Combined type sound barrier

A sound barrier and combined technology, applied in buildings, noise absorption devices, etc., can solve problems such as traffic accidents and driver visual fatigue, and achieve the effect of avoiding vehicle driving conditions and reducing the probability of car accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

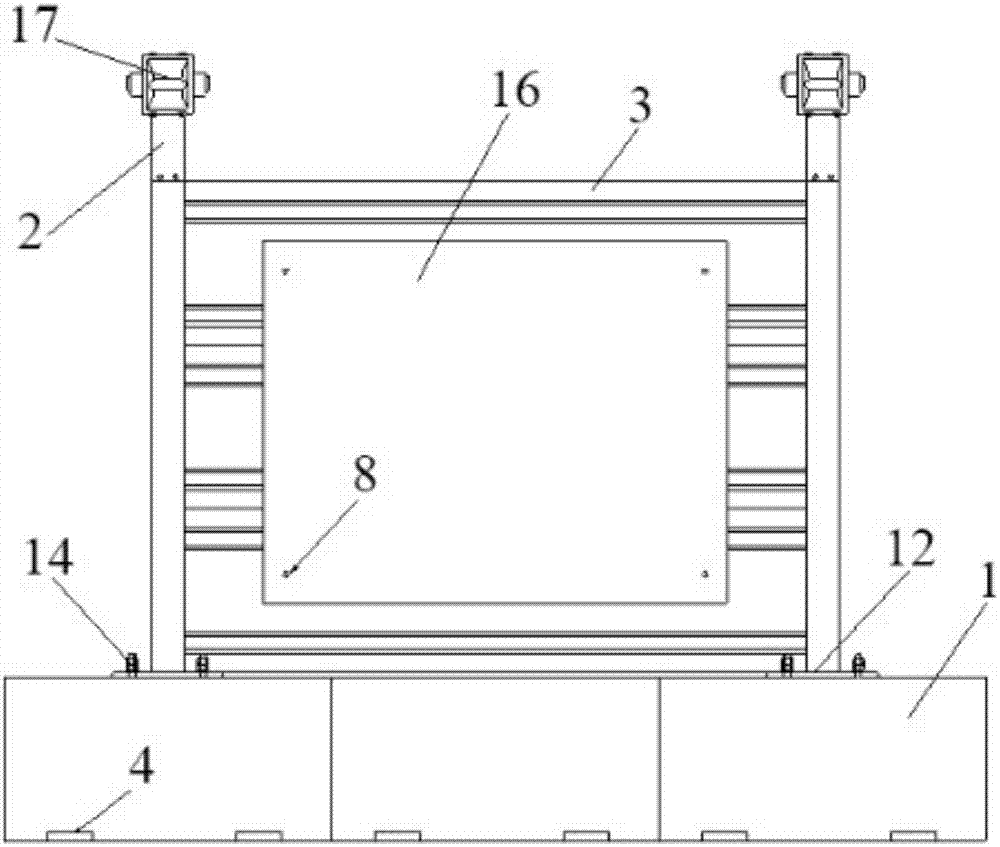

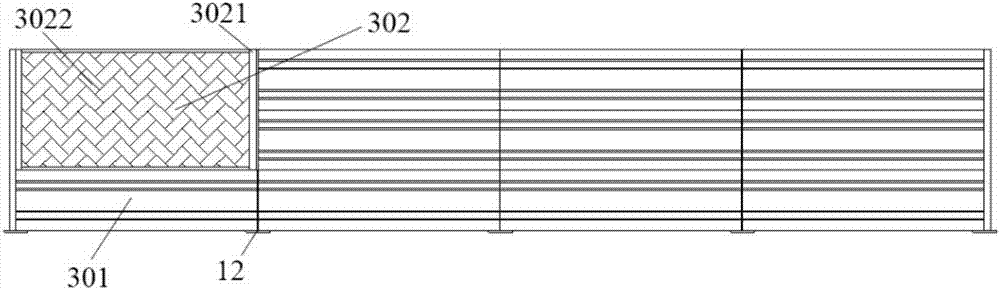

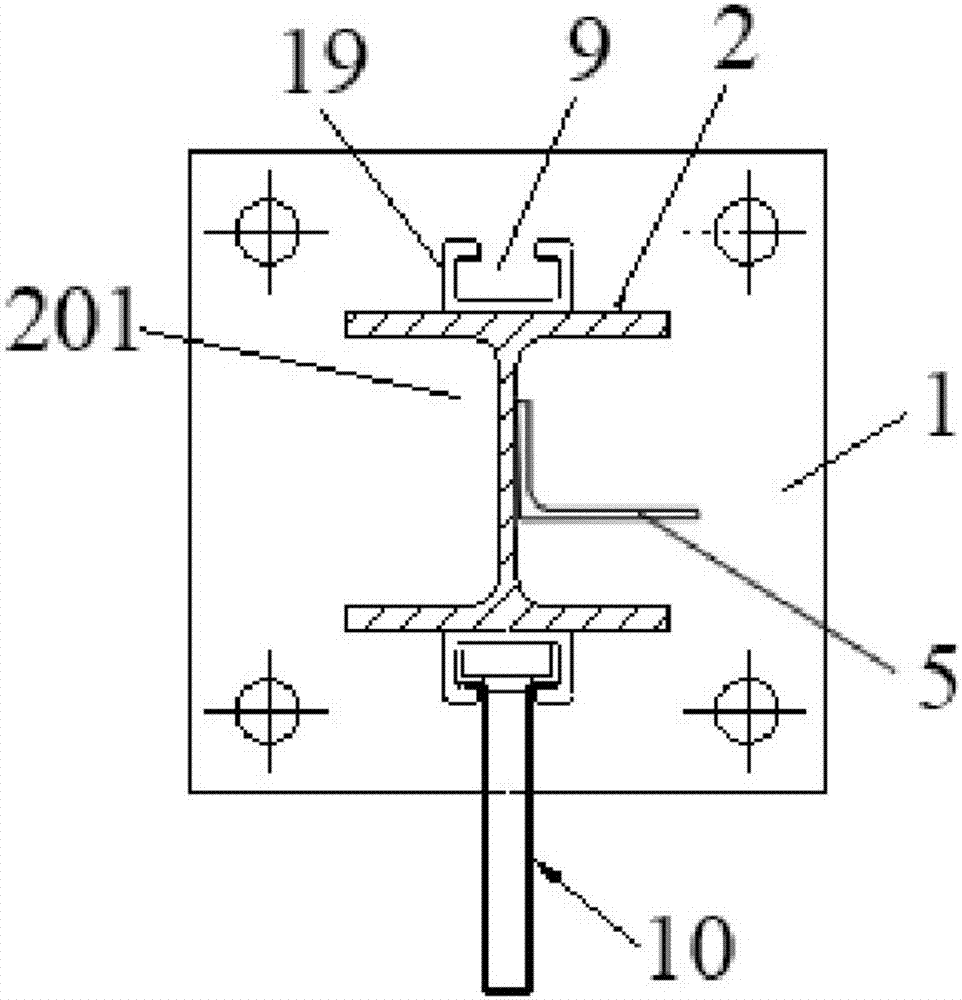

[0042] like figure 1 As shown, this embodiment provides a combined sound barrier, which includes a support 1 , several H-shaped steel columns 2 and several connecting plates 3 detachably installed between the H-shaped steel columns 2 . Wherein, the support 1 can be moved away from the ground, and the bottom of the support 1 is provided with a forklift hole 4, which is convenient for transportation. The H-shaped steel column 2 is detachably installed upright on the support 1, and the support 1 can be placed on the ground, without the need for the H-shaped steel column 2 to directly contact the soil. Therefore, corrosion damage to the bottom of the H-shaped steel column 2 is effectively avoided. , so that the combined sound barrier is easy to maintain and prolon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com