Improved flushing structure of closestool

A flushing and toilet technology, applied in the field of sanitary ware, can solve the problems of poor compatibility of toilets, pollution of domestic water sources, poor connectivity with tap water pipelines, etc., and achieve the effects of reasonable design, convenient flushing operation, and prevention of siphons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

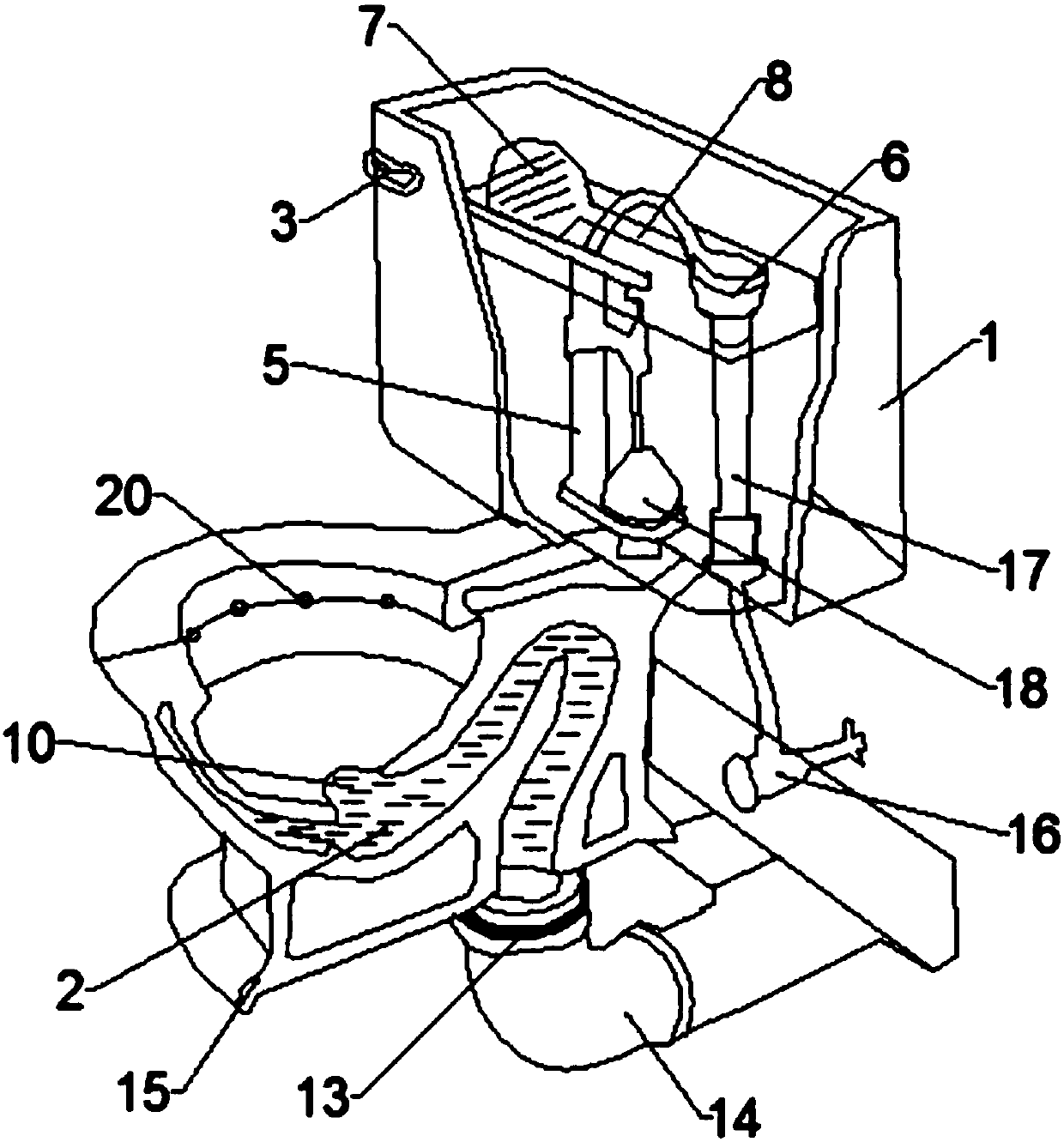

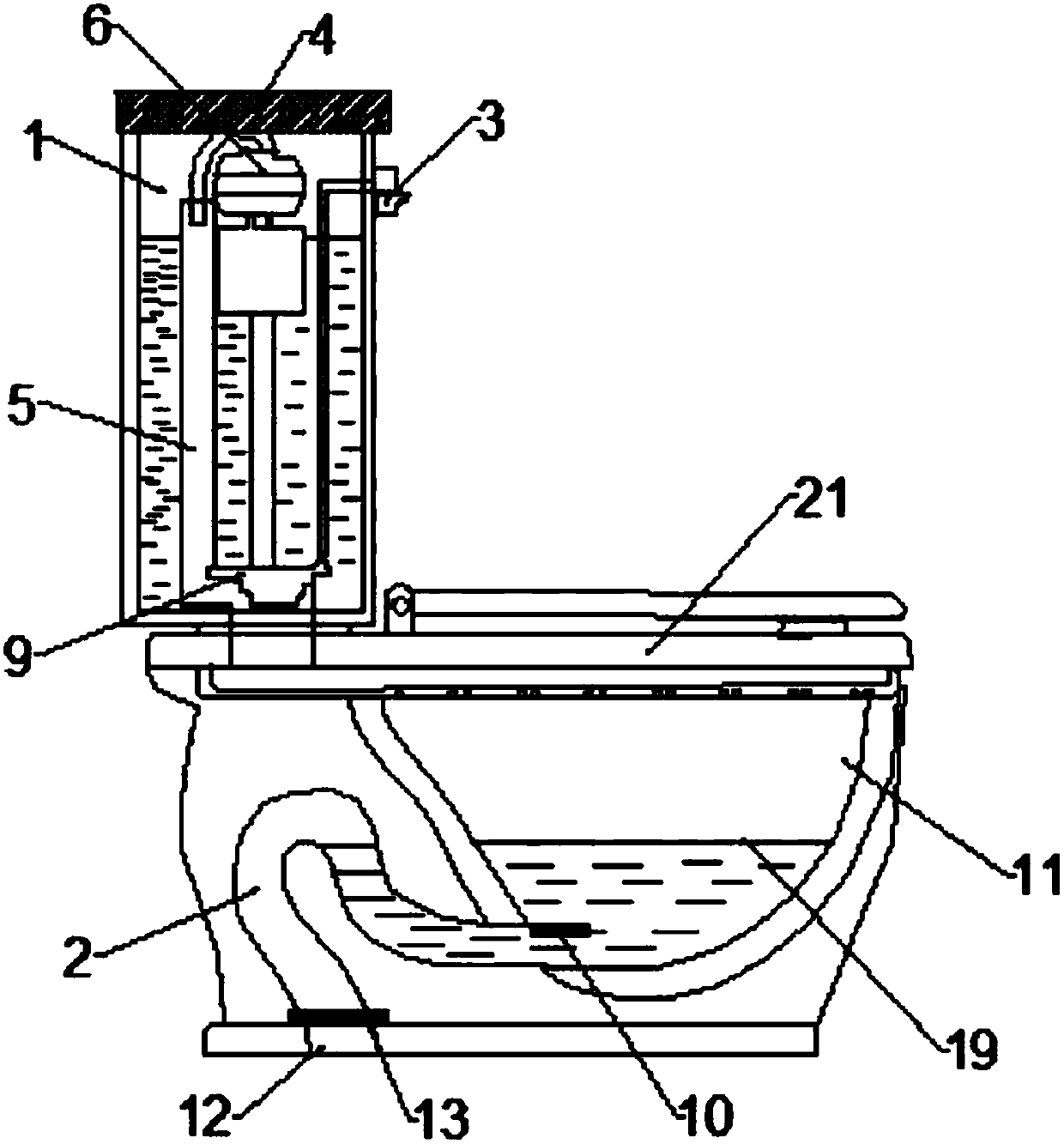

[0018] see figure 1 and figure 2 , the present invention provides a technical solution: an improved toilet flushing structure, including a water tank 1 and a siphon 2, a flushing handle 3 and a cover plate 4 are fixedly installed on the outer surface of the water tank 1, and the cover plate 4 is arranged on the water tank 3 On the upper surface of the water tank 1, an overflow pipe 5 is fixedly installed inside the water tank 1, and a water inlet pipe 17 is fixedly installed on the right side of the overflow pipe 5, and an angle valve 16 is also fixedly installed at the bottom of the water tank 1, and the top of the overflow pipe 5 An injection valve 6 and a floating ball 7 are fixedly installed, and the floating ball 7 is fixedly installed on the left side of the injection valve 6 through an air guide pipe 8 installed on its top, and a flush valve 9 is arranged at the bottom end of the overflow pipe 5, and the overflow Also be provided with water-stop rubber ring 18 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com