Sliding seat stroke adjusting and micro-moving auxiliary assembly for operating of screen printing machine

A technology of stroke adjustment and auxiliary components, applied in screen printing machines, printing machines, rotary printing machines, etc., can solve the problems of abnormal displacement distance and direction of the carriage, affecting the running effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

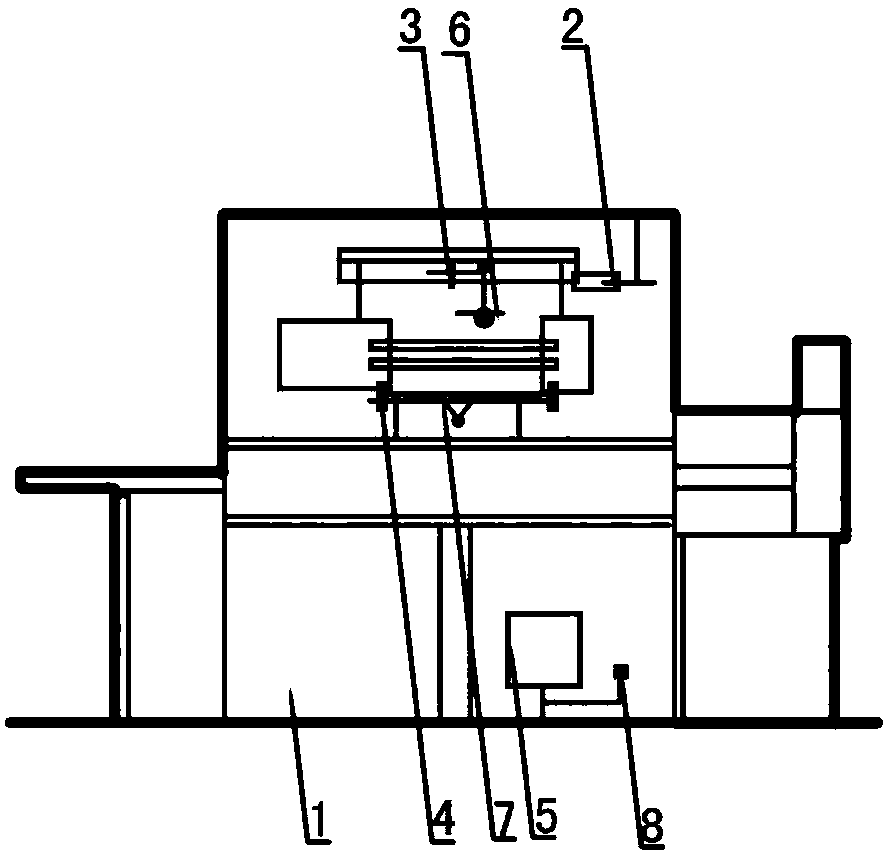

[0012] Embodiment: as shown in the accompanying drawing. The micro-movement auxiliary assembly for the stroke adjustment of the sliding seat in the operation of the screen printing machine includes a body (1), on which a fixed-point reference module (2), a displacement sensing module (3), a contact sensing module (4), and a management module are set (5), during operation, the fixed-point reference module (2) is set at the initial position of the sliding seat, the displacement sensing module (3) is set on the sliding seat part, the contact sensing module (4) is set on the pedal part, and the management module ( 5) Process comprehensive information.

[0013] The silk screen printing machine operates the sliding seat stroke adjustment micro-motion auxiliary component, and the orientation sensing module (6) is set on the displacement sensing module (3) to sense the movement of the sliding seat in the up, down, left, and right directions in real time.

[0014] The silk screen prin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com