Pulley protection device of stage hanging steel wire rope

A protective device and single-point technology, applied in the field of wire rope pulleys, can solve the problems of increased theater maintenance costs, increased pulley bearing capacity, hidden dangers to performers, etc., to avoid breakage of the pulley structure, strengthen the pulley bearing capacity, and reduce the occurrence of safety accidents. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

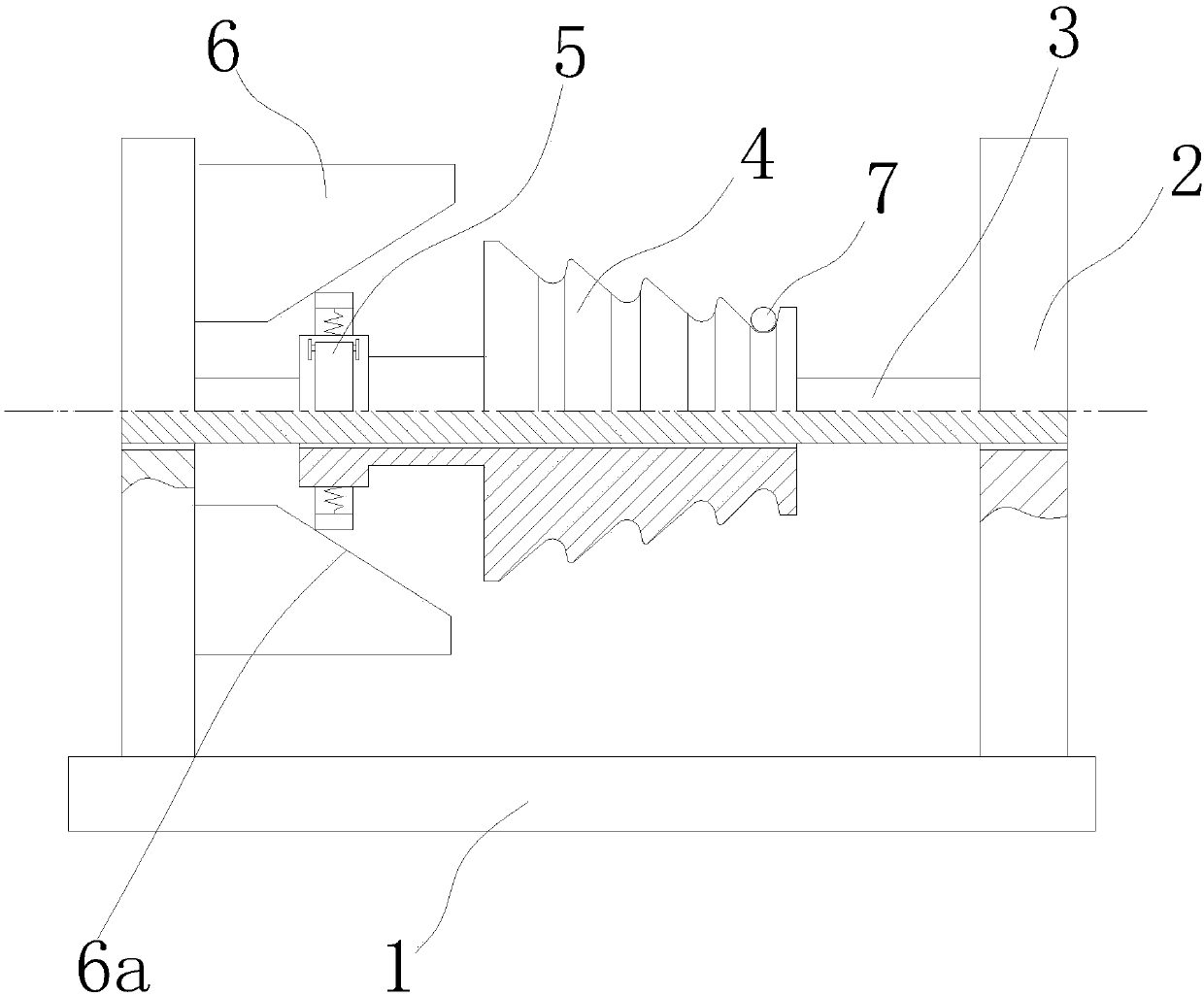

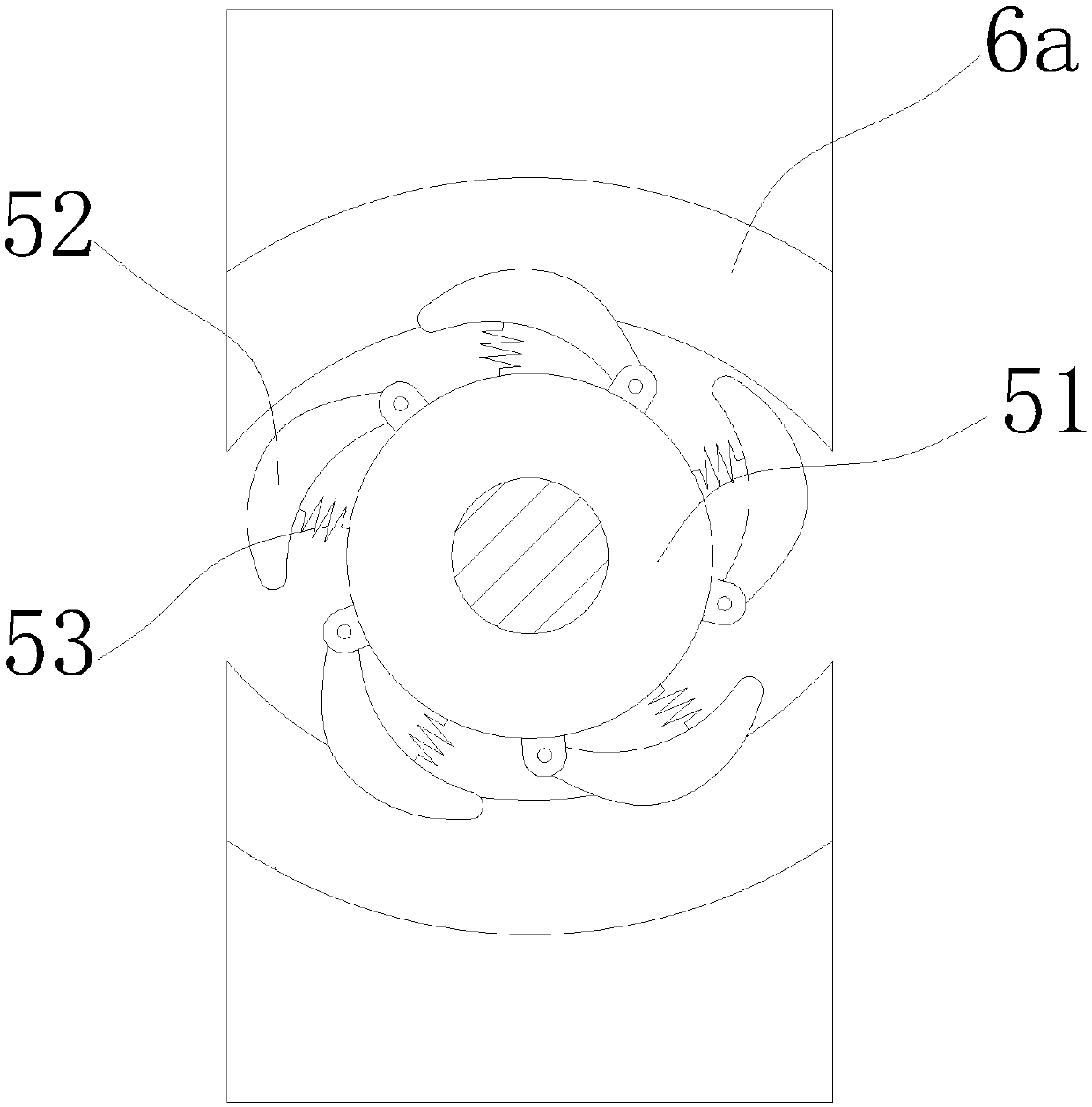

[0016] Such as Figure 1 to Figure 3 As shown, a pulley protection device for stage single-point suspension includes a bottom mounting plate 1, side mounting plates 2 fixed on the left and right sides of the bottom mounting plate 1, and a long shaft 3 connected to the side mounting plate 2. A conical pulley 4 is installed on the shaft 3, and the conical pulley 4 is fixedly connected with a flywheel mechanism 5 installed on the long axis 3 and performing centrifugal movement, and a guide block is fixed on the side mounting plate 2 near the flywheel mechanism 5 6. The guide block 6 is provided with a tapered arc surface 6a which cooperates with the flywheel mechanism 5 and whose radius gradually increases.

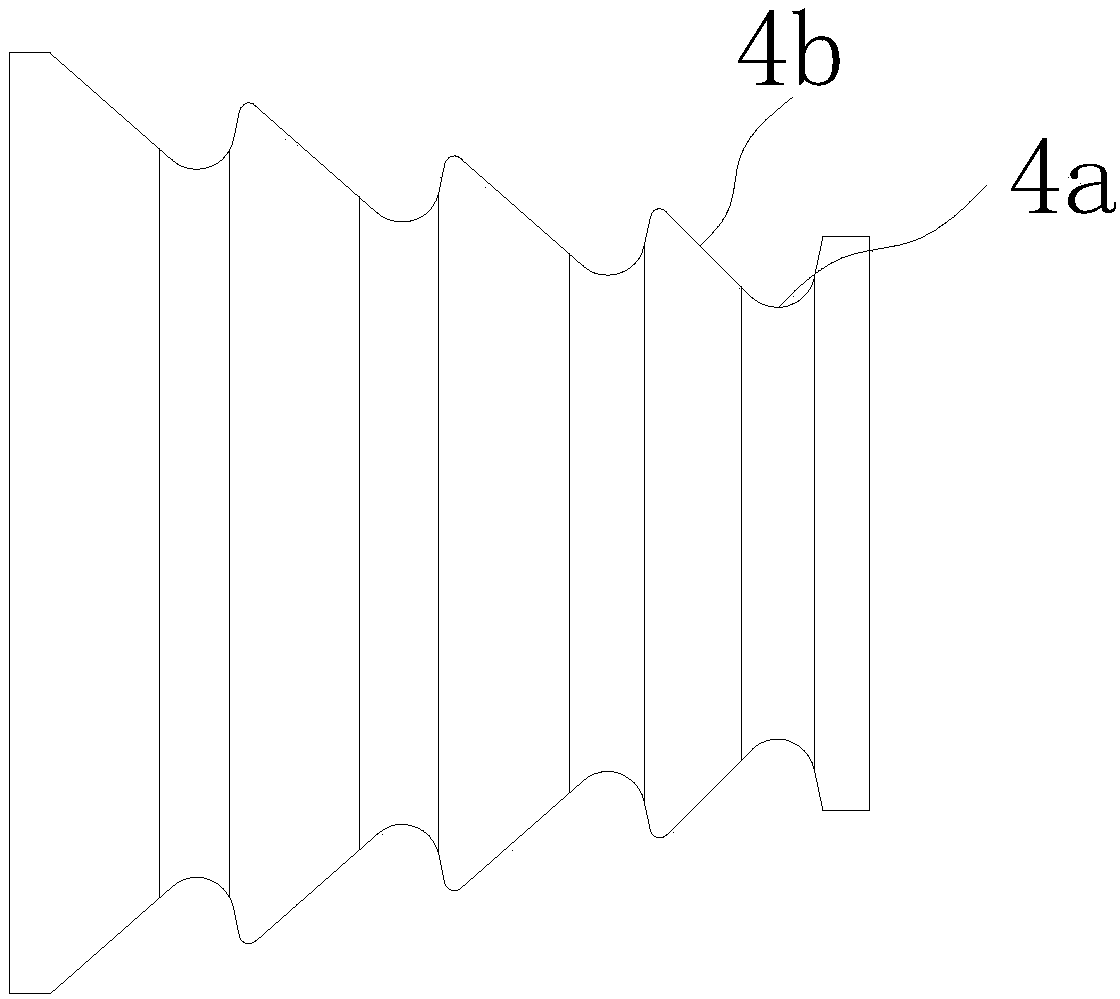

[0017] The tapered pulley 4 is evenly distributed with several rope grooves 4a a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com