Cross-over type bridge cast-in-place platform simulating identical load sectional pre-pressing construction method

A construction method and leap-forward technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of inability to simulate and high cost, and achieve the effect of reducing equipment shifts, waste materials, and preloading time.

Active Publication Date: 2018-04-13

CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG +1

View PDF2 Cites 32 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] When a large number of bridges in the prior art use steel pipe piles + Bailey beams as the support system, the actual working conditions cannot be simulated by using time-sharing preloading span by span, and there is a problem of high cost whe

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a cross-over type bridge cast-in-place platform simulating identical load sectional pre-pressing construction method, and belongs to the technical field of cast-in-place concrete bridge pre-pressing. The problems that a practical working condition cannot be simulated by span-by-span time-share pre-pressing while the cost is high by adopting whole bridge simultaneous pre-pressing when a bridge adopts a steel pipe pile and a Bailey beam to serve as a supporting system are solved. According to the construction method, Midas-civil is adopted to conduct modeling calculation,the deformation situation of a support can be analyzed in advance, when span-by-span pre-pressing loading is conducted, load arrangement is conducted pointedly so as to be equivalent to full span loading, and the purpose that span-by-span pre-pressing simulates full span pre-pressing is achieved. Because limited pre-pressing materials can be used repeatedly, one-time investment is greatly reducedaccordingly, the construction period is shortened, and the cost is saved.

Description

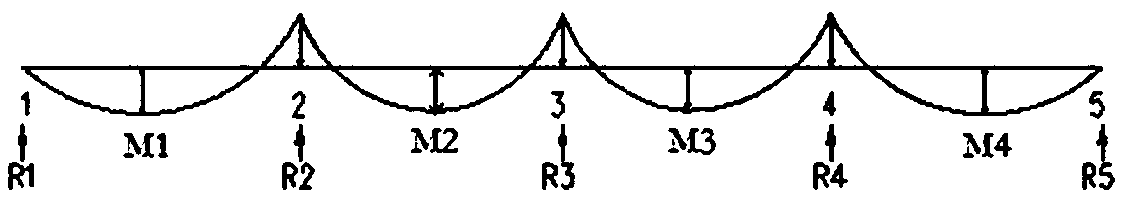

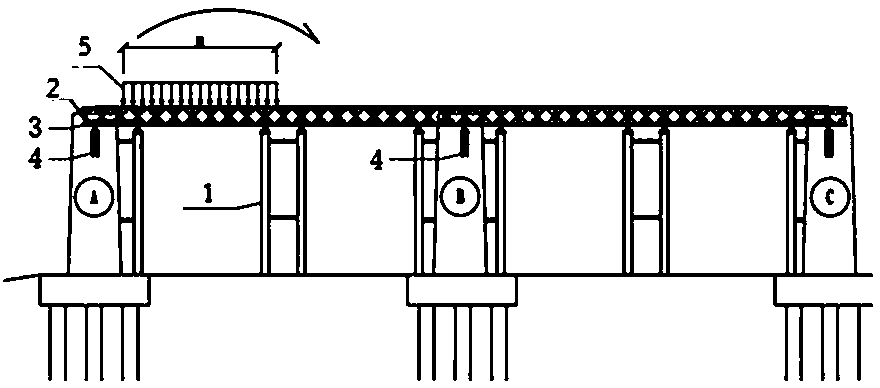

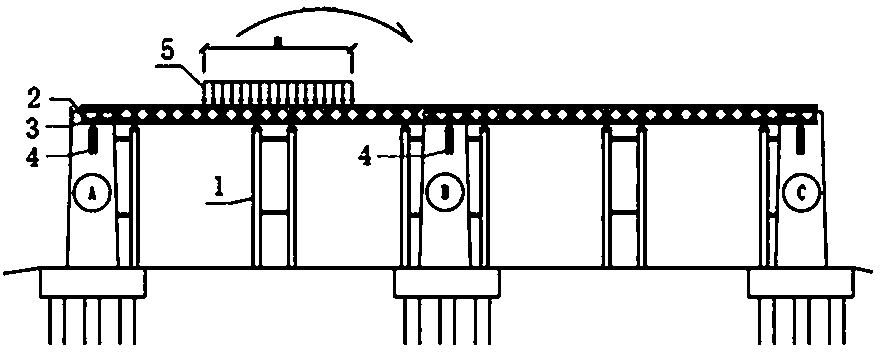

technical field [0001] The invention belongs to the technical field of preloading of cast-in-place concrete bridge supports, and specifically relates to a segmental preloading construction method for supports of cast-in-situ continuous beam bridges using steel pipe columns and Bailey beams as support systems. Background technique [0002] With the continuous and rapid advancement of my country's infrastructure construction, a large number of cast-in-place bridges need to be erected, and the preloading test is an important link to verify the safety of cast-in-place bridge supports and eliminate related inelastic deformation. In order to reduce the amount of supports erected, spanning supports formed by steel pipe columns and Bailey beams are usually used as the support system for bridge cast-in-place construction. [0003] For long-span continuous girder bridges, the preloading of supports can be divided into simultaneous preloading of the whole bridge and time-sharing preloa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E01D21/00G06F17/50

CPCE01D21/00G06F30/13G06F2119/06

Inventor 杨翔张庆明易雄川江真张志飞李丽萍陶伟向起来李晓倩

Owner CHONGQING CONSTR ENG MUNICIPAL TRAFFIC ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com