A full-section pouring monitoring system and monitoring method

A monitoring system and full-section technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problems of high stress on the formwork system, achieve the effect of ensuring quality, improving dimensional accuracy, and ensuring dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] This embodiment provides a monitoring system for full-section pouring of immersed tube segments.

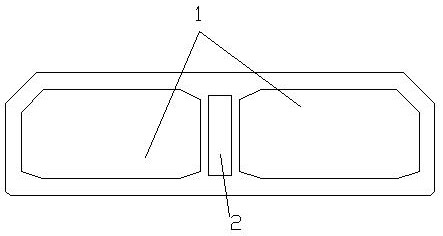

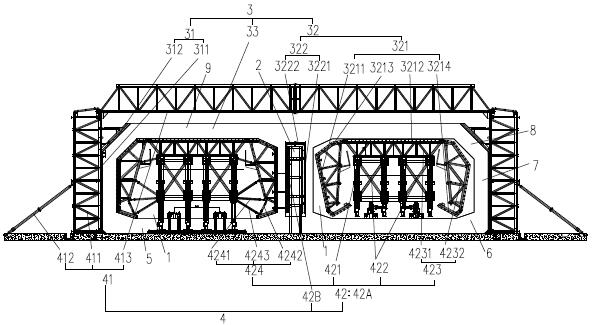

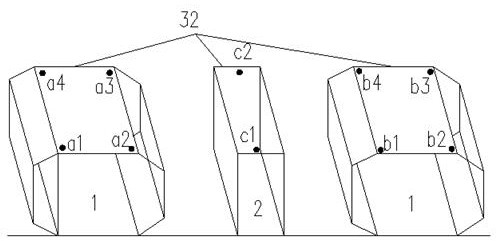

[0094] like figure 1 and figure 2 As shown in the figure, the immersed tube structure is a three-chamber structure, including the traffic lanes 1 on the left and right sides, and the middle corridor 2 in the middle. The immersed tube formwork system is used in the full-section pouring process of the immersed tube segment, including the pouring formwork 3 and the formwork. Support system 4. The formwork support system 4 is used to support the pouring formwork 3. The pouring formwork 3 includes an outer mold 31 and an inner mold 32. The formwork support system 4 includes an outer mold support system 41 and an inner mold support system 42. This embodiment The full-section pouring monitoring system of the example includes the preload monitoring of the formwork system and the real-time monitoring of the formwork system during the pouring process. The real-time monitoring incl...

Embodiment 2

[0100] This embodiment provides a preload monitoring method for full-section pouring. During the full-section pouring process, the formwork system will be subjected to a large load and there will be large deformation, including elastic deformation and inelastic deformation. Apply preload load for preload monitoring, eliminate the inelastic deformation of the formwork system, and measure the elastic deformation of the formwork system after being subjected to construction loads, and the bearing capacity and stability of the formwork system can be checked through preload monitoring. The pour monitoring system includes preload monitoring of the formwork system.

[0101] The preload monitoring method for full-section pouring includes the following steps:

[0102] a. Assemble the formwork system, and arrange multiple monitoring points on the pouring formwork;

[0103] b. Apply preloading load, adopt equal load preloading, divide the preloading area into several preloading units and...

Embodiment 3

[0116] The present embodiment provides a monitoring method for the full-section pouring construction process of the immersed tube section. The monitoring method, as a part of the full-section pouring monitoring system, includes the following implementation steps:

[0117] a. Measurement preparation, including establishing monitoring benchmarks;

[0118] b. Adjust the position of the formwork system, and arrange a plurality of monitoring points on the pouring formwork and the formwork support system respectively, and each monitoring point on the formwork support system is provided with a stress sensor, and the stress sensor is connected to the a data display and analysis system, the data display and analysis system is used for receiving the data of the stress sensor and performing summarization, analysis and display, and the data display and analysis system is preset with an early warning value obtained according to the template support system structure;

[0119] c. Collect the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com