A stent preloading device and method

A technology of support bottom and reaction force frame, which is applied in the field of support preloading device for template engineering preloading, which can solve the problems of non-elastic deformation of support and construction safety, so as to eliminate non-elastic deformation, ensure construction safety, and reduce manpower and material resources the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

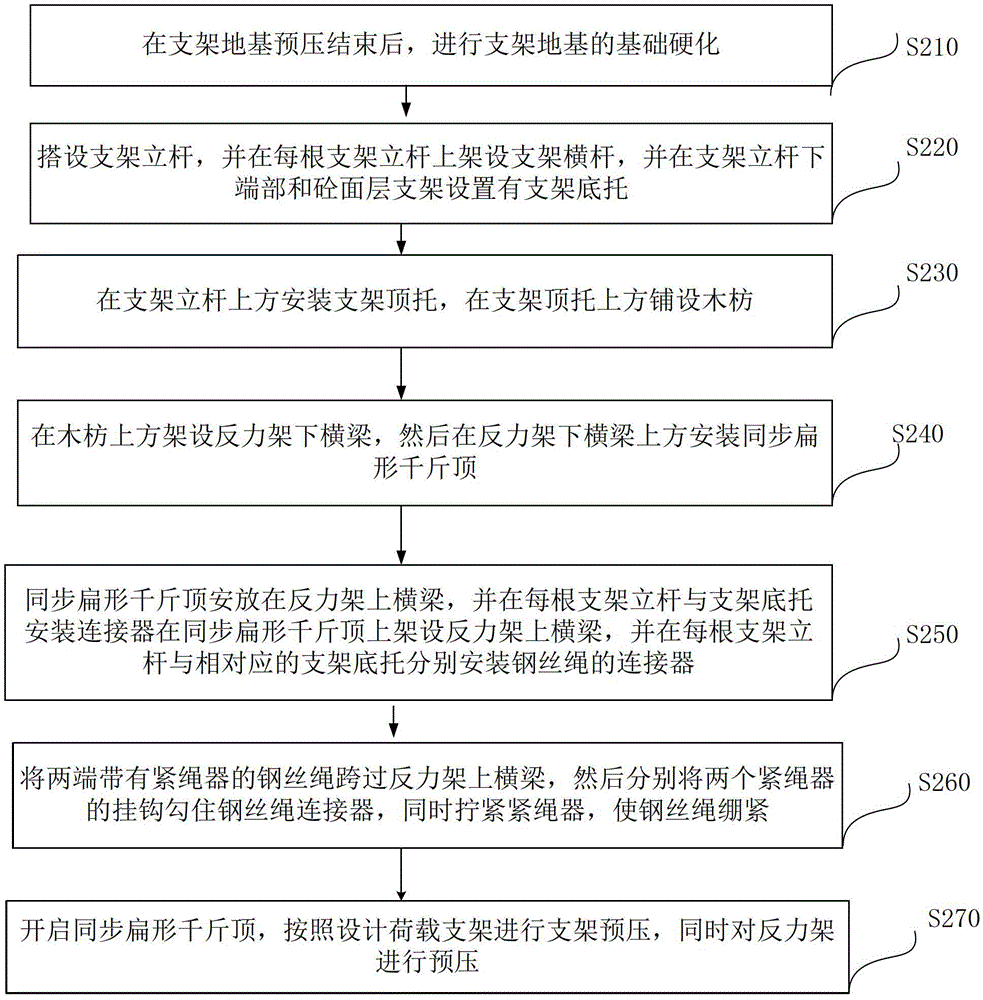

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

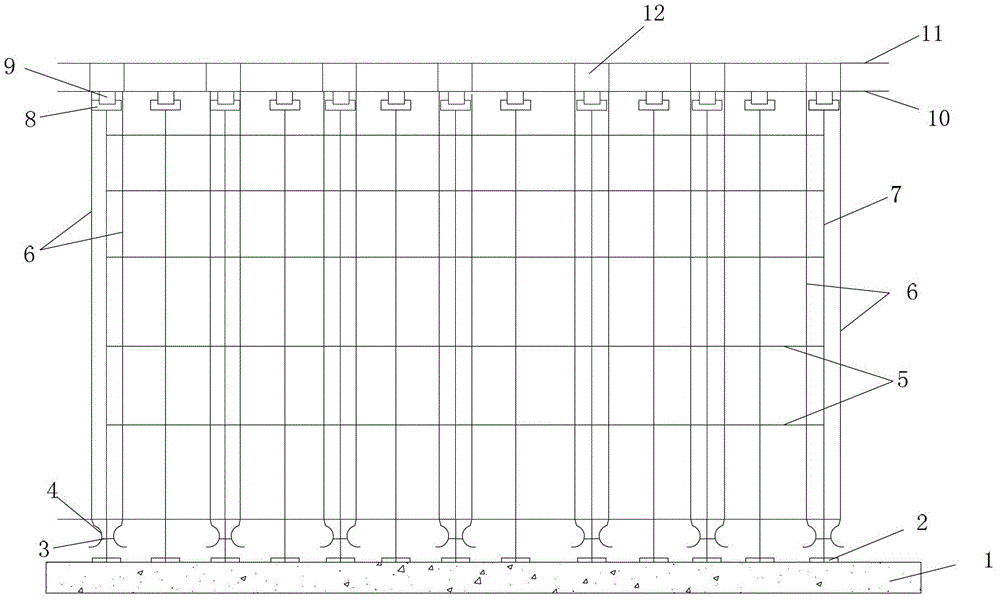

[0036] figure 1 It is a diagram of a stent preloading device according to an embodiment of the present invention.

[0037] Such as figure 1 As shown, the present invention provides a support preloading device, which includes a synchronous flat jack 12, a reaction force frame, a steel wire rope 6, a rope tightener 4 and a support.

[0038] Wherein, the reaction frame comprises the upper beam 11 of the reaction frame and the lower beam 10 of the reaction frame, the lower beam 10 of the reaction frame and the upper beam 11 of the reaction frame are steel beams, and the upper beam 11 of the reaction frame is provided with a smaller steel beam. Fastener clamp (not in figure 1 Marked above), used to fix the wire rope 6.

[0039] The support includes a support pole 7 and a support cross bar 5 perpendicular to the support pole 7 .

[0040] Corres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com