An intelligent bridge hanging basket preloading device and its control method

A control method and preloading technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of boom collision, inability to truly reflect the working mechanical properties of hanging baskets, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the drawings are in simplified form and inaccurate proportions, and are only used to facilitate and clearly illustrate the purpose of the present invention.

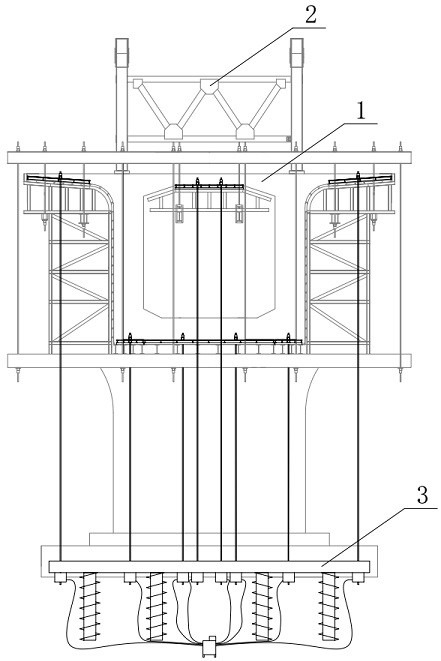

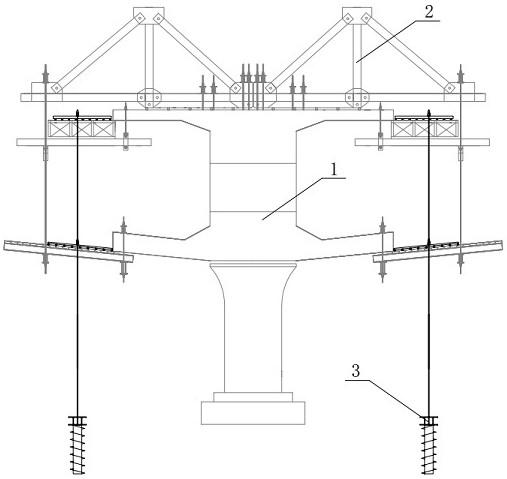

[0030] Such as figure 1 and figure 2 As shown, after the hanging basket is installed and debugged on the beam body of the bridge, the present invention can be deployed, that is, the intelligent preloading system of the bridge hanging basket. This system includes a press frame module, a ground anchor module, an intelligent loading module and a monitoring module.

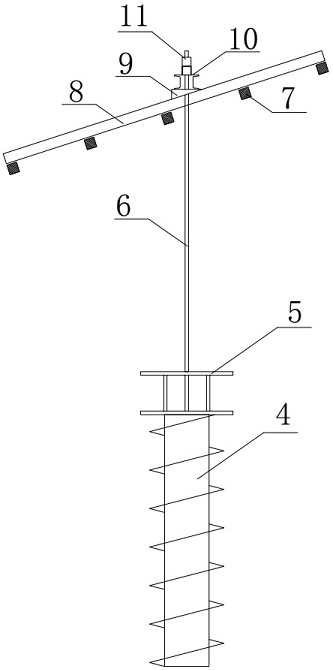

[0031] First, install the press frame module on the hanging basket, including steel strand 6, square wood 7, I-beam 8, leveling wedge 9, double channel steel 10, and steel strand anchor 11. According to the drawing of the box girder body, it is divided into four parts:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com