Continuous rigid frame bridge cast-in-place bracket pre-pressing device and method

A rigid-frame bridge and bracket technology is applied in the field of cast-in-place bracket preloading devices for continuous rigid-frame bridges, which can solve the problems of unreusable preloading devices, low preloading efficiency, concrete falling off, and the like, and achieve low construction investment costs. , High utilization rate, the effect of eliminating inelastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

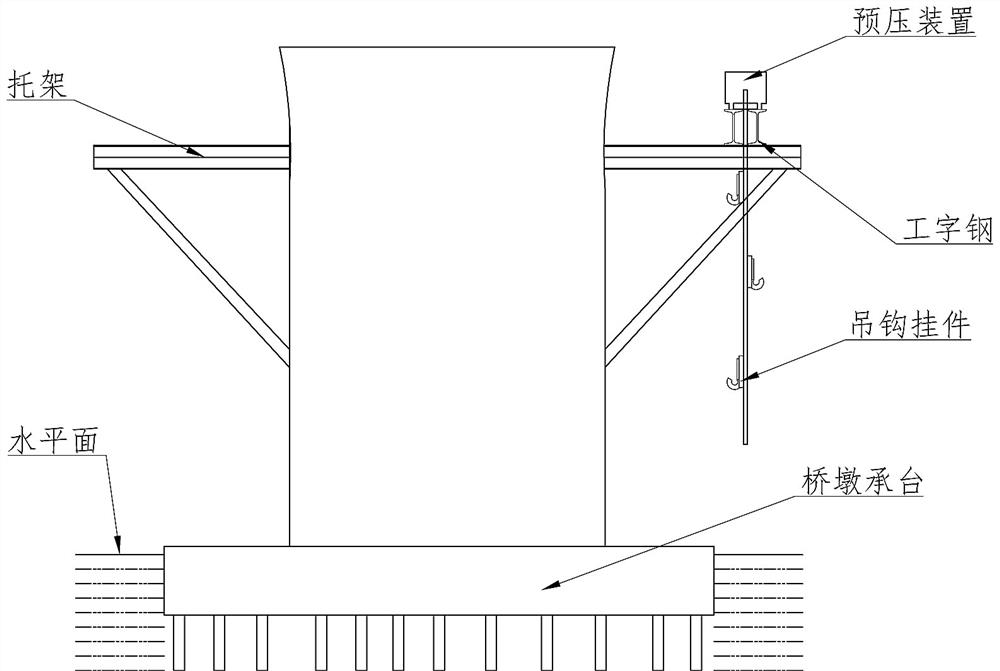

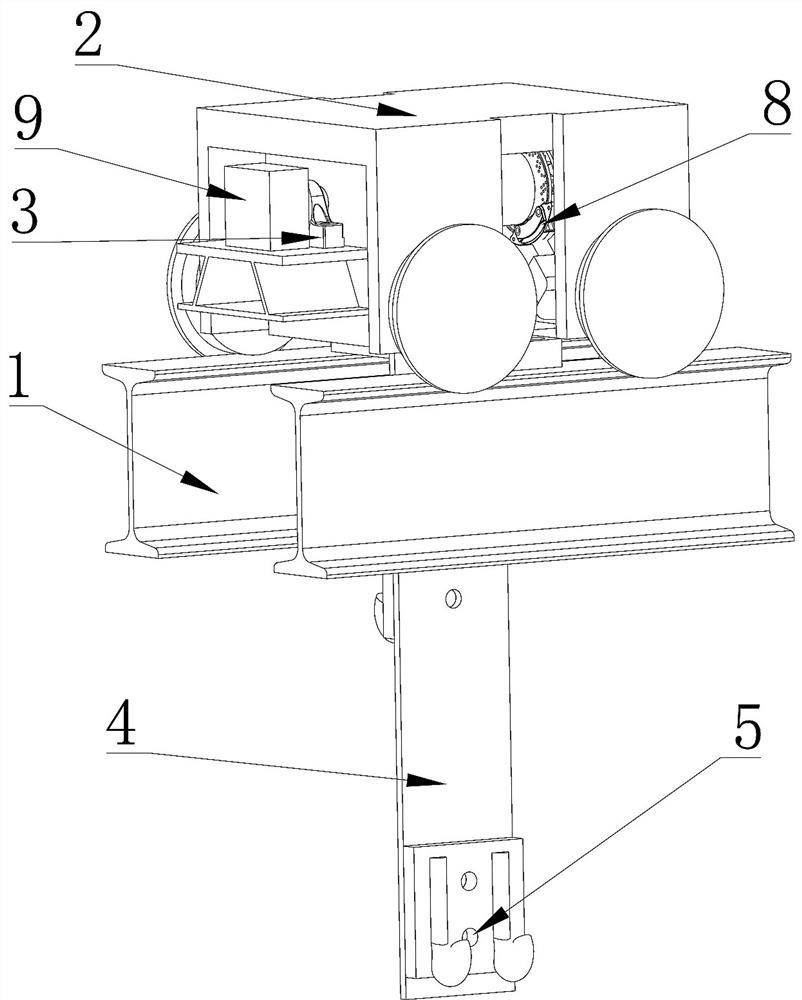

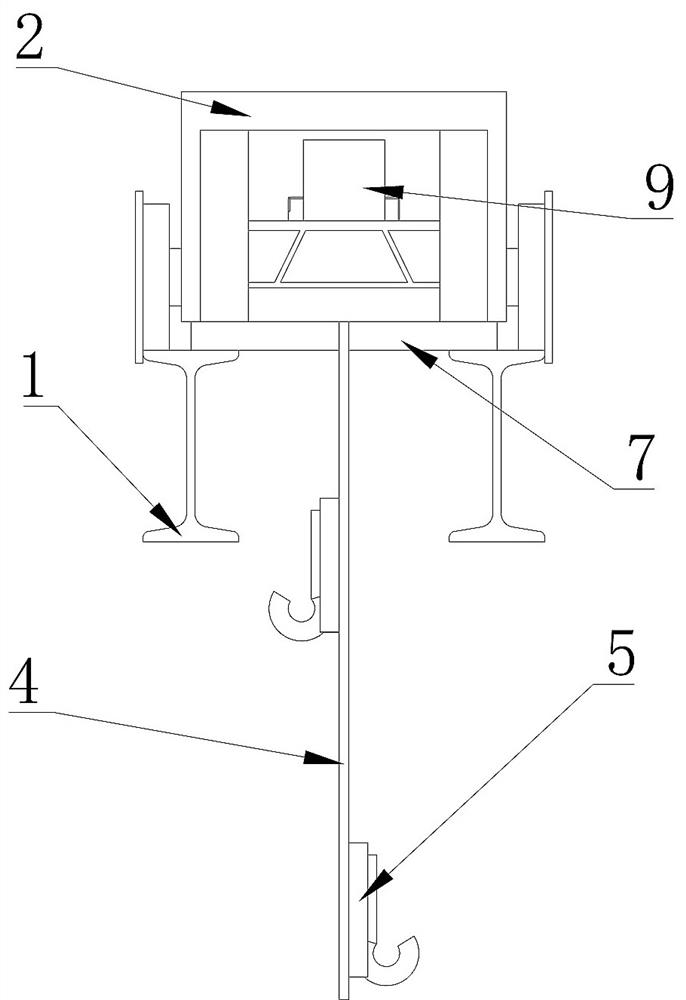

[0038] Such as Figure 1~9shows a continuous rigid frame bridge cast-in-place bracket preloading device and method, including a plurality of I-beams 1 installed on the bracket, and is characterized in that: a plurality of I-beams 1 are provided with slidable moving devices 2. The moving device 2 is provided with a rotatable rotating shaft 601. The rotating shaft 601 is provided with a through groove 602. One side of the rotating shaft 601 is provided with a motor 9. The output shaft of the motor 9 is fixedly connected with one end of the rotating shaft 601. The rotating shaft 601 is provided with a coiled steel plate sling 4, and one end of the steel plate sling 4 is fixed against the through groove 602. There are multiple detachable sling pendants 5 on both sides of the steel plate sling 4, and a shear bar is also provided on the steel plate sling 4. The hole 402, the shear rod 7 runs through the shear rod hole 402 and leans against the shear rod hole 402, and the two ends of...

Embodiment 2

[0050] Further illustrate in conjunction with embodiment 1, as Figure 1~9 As shown, the method is: in the factory, the shear bar 7 and the suspender 5 are processed and formed according to the appropriate situation, and the steel plate suspender 4 is opened according to the size of the shear bar 7 and the suspender 5; the steel plate is placed on the ground. One end of sling 4 is fixed in the through groove 602 by fixing column 604, and motor 9 drives rotating shaft 601 to rotate, and drives steel plate sling 4 to wind up on rotating shaft 601, and reserved sling pendant 5 is not installed on steel plate sling 4; The preloading device of the cast-in-place bracket of the bridge is hoisted on the bracket as a whole, the position of the I-beam 1 installed on the bracket is adjusted, and the distance between the I-beam 1 is adjusted so that the I-beam 1 just passes through the sling pendant 5 and the Install and connect the steel plate sling 4, fix the I-beam 1 on the top surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com