Heat preservation sealing module blocking body

A technology of sealing modules and blocking bodies, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., and can solve problems such as seepage plugging, resource loss and environmental problems, and large land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

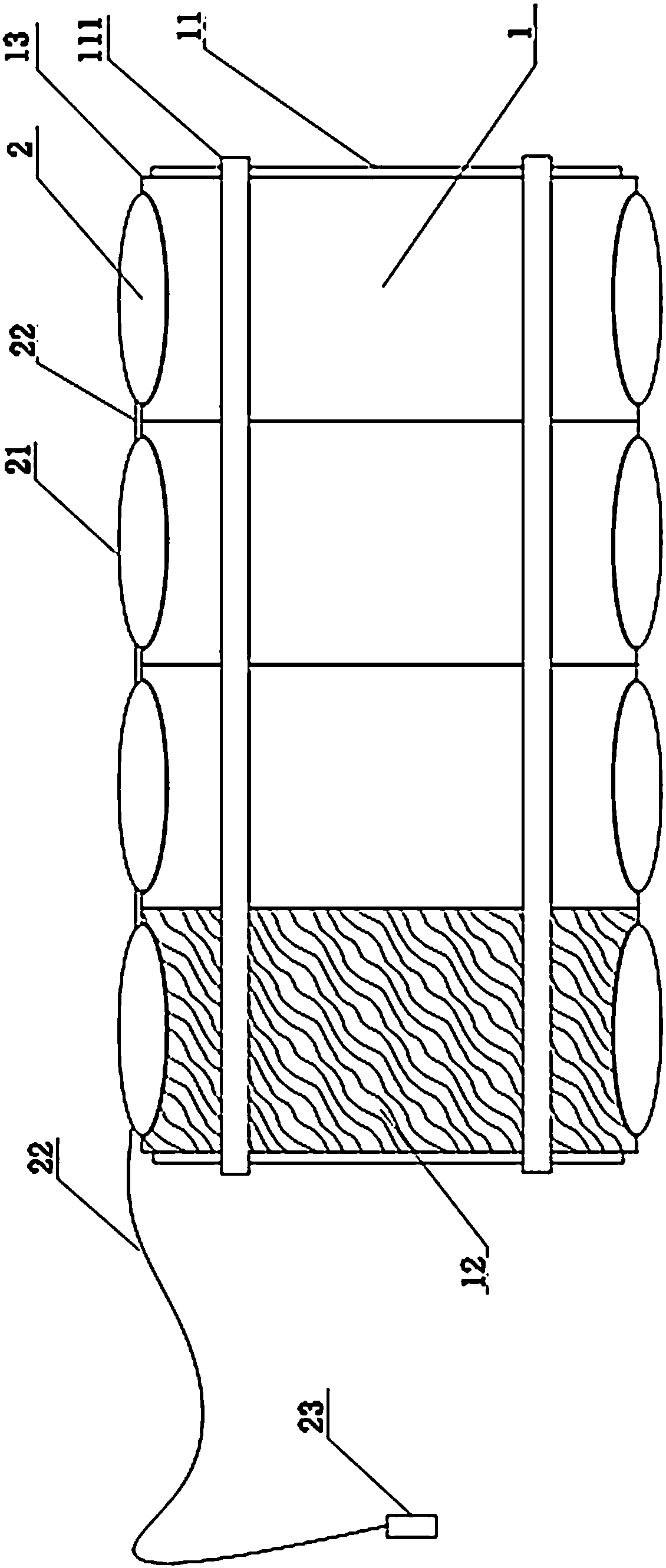

[0012] The thermal insulation sealing module blocking body includes a module (1) and an air bag (2), and is characterized in that: the module (1) is composed of an end cover (11), an insulation layer (12), and a module body (13); the module body (13) Built-in insulation layer (12), sealed end caps (11) at both ends, reserved pipeline through-holes (111) on the end caps (11); nozzle (23); the annular air bag body (21) is connected with the air nozzle (23) through the trachea (22), and the air nozzle (23) is a one-way air guide device, and the annular air bag body (21) is imprisoned in the module body (13 ) outside.

[0013] As mentioned above, the module body (13) can be connected with multiple seals to form a multi-connected module body, and the end caps (11) are sealed at both ends; the annular air bag body (21) can also be connected to each other through the trachea (22) to form The multi-joint annular air bag body is imprisoned on the outside of the multi-joint module body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com