Using method of heat storage, boiling, burning, precipitation and purification device for VOCs waste gas absorbed solid waste

A solid waste, regenerative combustion technology, applied in the direction of combustion method, combustion type, combustion technology mitigation, etc., can solve the problems of coking, uneven fluidization, furnace temperature not reaching the effective pyrolysis temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

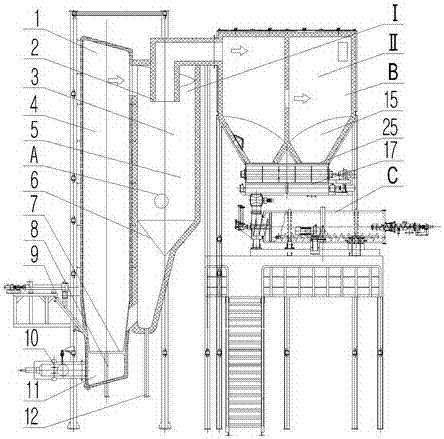

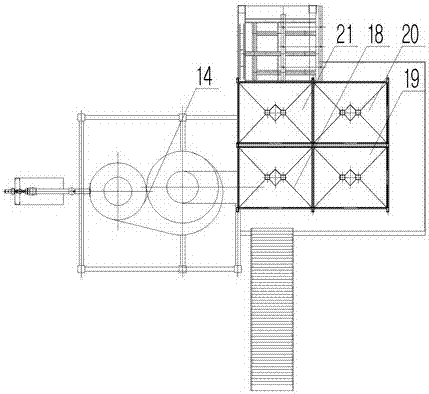

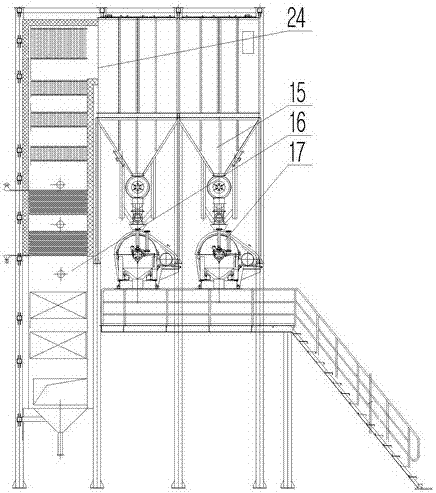

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 As shown, a method for using a thermal storage boiling combustion sedimentation purification device for adsorbing VOCs waste gas solid waste is characterized in that:

[0039] Step 1: Adsorbing VOCs waste gas and solid waste regenerated fuel particles is sent into the furnace 1 by the screw feed assembly 9, and a 30cm material layer (fluidized layer) is evenly laid on the water-cooled air distribution plate 7, and then the primary air is sent to the water-cooled air chamber assembly 11 , to ensure uniform air distribution and good fluidization of the material layer, and then start to ignite the ignition burner 10 to raise the temperature of the furnace body 4 and reach the ignition temperature. , carried by the high-temperature flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com