Hot compress pad

A hot compress and heat technology, applied in the shape of heating elements, heating appliances for therapeutic treatment, cooling appliances for therapeutic treatment, etc., can solve the problems of complex overall structure and increased cost, and achieve the reduction of material and processing costs and power saving energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

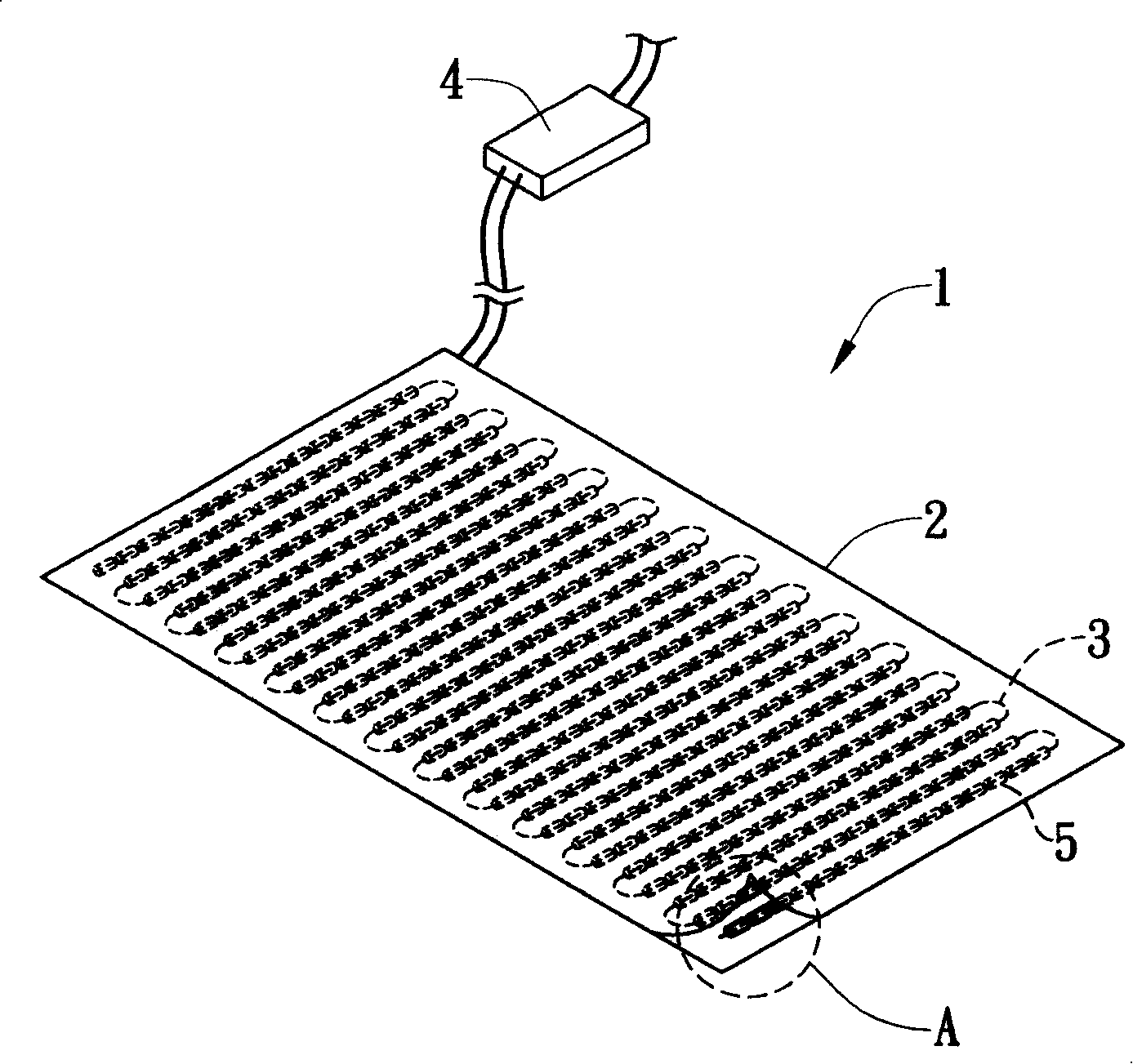

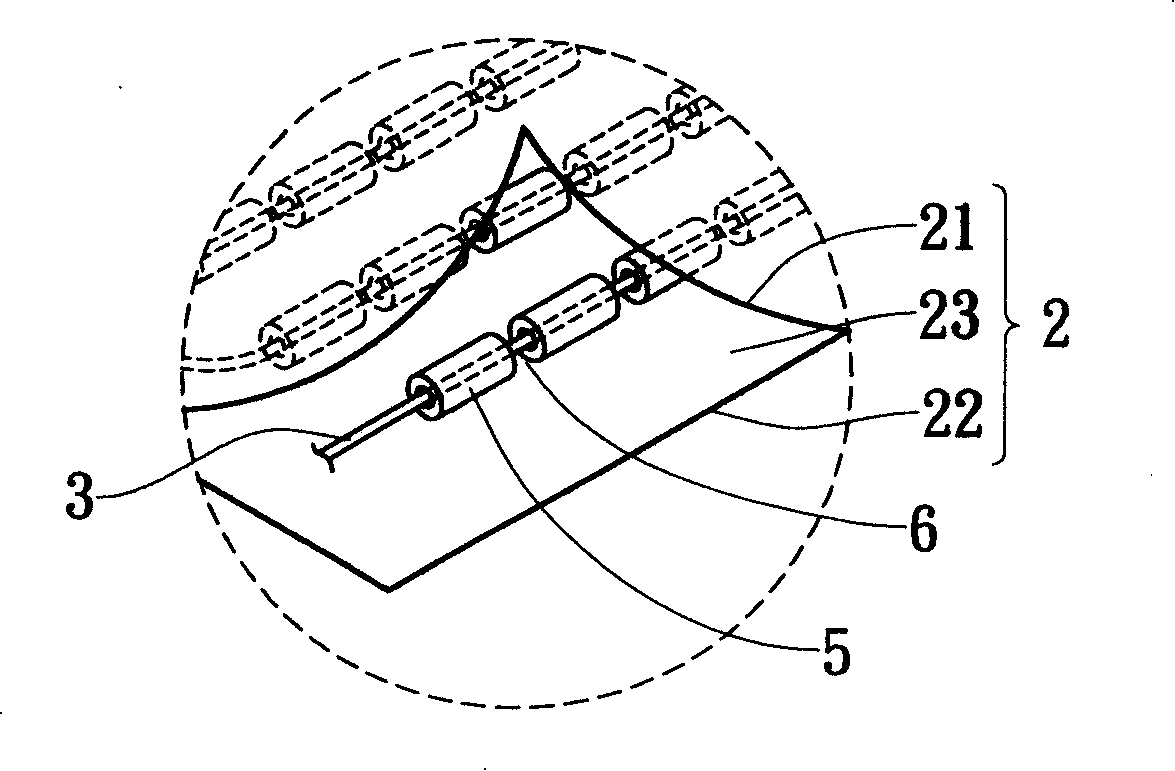

[0024] see figure 1 , figure 2 As shown, it is a preferred embodiment of the heating pad 1 of the present invention, including a bag body 2 , a heating wire 3 , a controller 4 and a plurality of heat preservation components 5 .

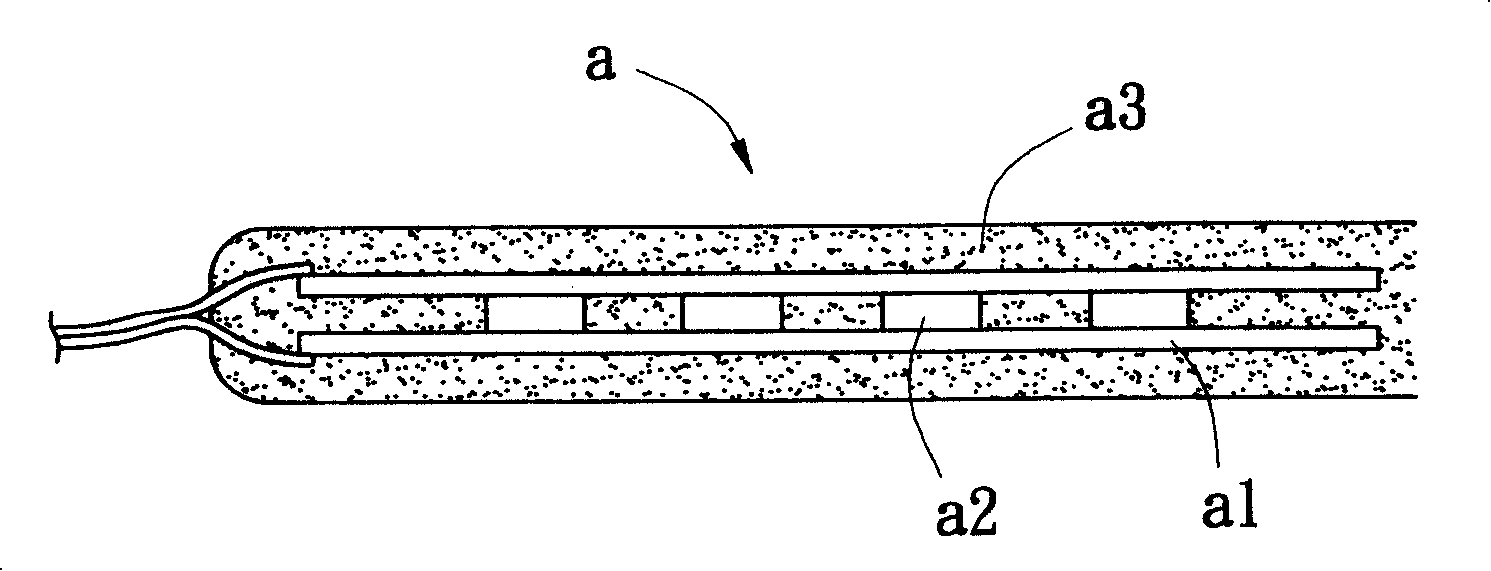

[0025] The bag body 2 is formed by stacking a surface layer 21 and a bottom layer 22 up and down to form an accommodating space 23 inside the bag body 2 . The heating wire 3 is accommodated in the bag body 2 and combined in the accommodating space 23 sandwiched between the surface layer 21 and the bottom layer 22 in a manner of continuous bending on the same plane. One end of the heating wire 3 is connected to a power supply, and the other end is grounded, and a controller 4 is connected between the heating wire 3 and the power supply. During implementation, a trigger circuit, a temperature feedback circuit and a microprocessor connected to each other are provided in the controller 4, and the trigger circuit is connected with the heating wire 3, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com