Coupling method of small-angle ultrasonic monitoring sensor of inservice wind power main shaft

A wind power spindle and small-angle technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and instruments. It can solve the problems of high processing difficulty, low yield, and long coupling agent time. problem, to achieve the effect of solving the problem of long-term coupling and small-angle ultrasonic detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

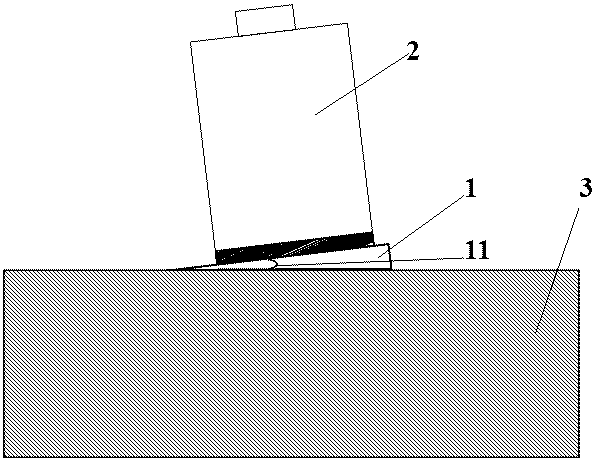

[0009] Examples such as figure 1 As shown, a coupling method of small-angle ultrasonic monitoring sensors for wind power main shafts in service is characterized in that a sound-conducting flexible wedge 1 is bonded and fixed on the detection surface of the ultrasonic straight probe 2, and the sound-conducting flexible wedge 1 The cross section is a small angle right triangle, the small angle is to control the angle range of the small acute angle 11 of the sound guiding flexible wedge 11 to 3 °, and the ultrasonic straight probe 2 is perpendicular to the long right angle of the sound guiding flexible wedge 1 On the other hand, the inclined surface of the sound guiding flexible wedge 1 is bonded and fixed on the detection surface of the monitored main shaft 3 as the detection surface, so that the gapless coupling function between the ultrasonic straight probe 2 and the monitored main shaft 3 detection surface is realized, and the ultrasonic straight probe is realized at the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com