Wire positioning device of insulator

A technology for positioning devices and insulators, which is applied in the direction of insulators, electrical components, circuits, etc., can solve the problems of wire casualties, wire wear, and broken wires, and achieve the effects of avoiding fixed binding methods, reducing wear rates, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

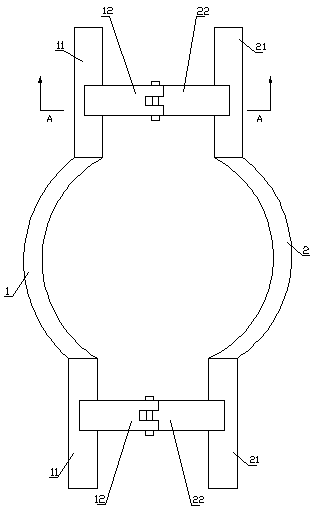

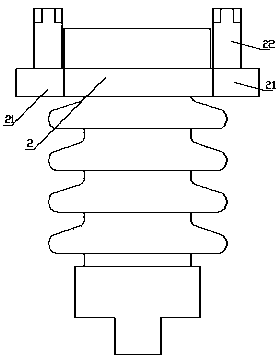

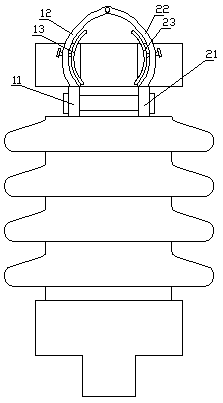

[0016] Such as figure 1 The shown insulator wire positioning device includes a first semicircular clamp 1 installed between the upper cap of the insulator and the ceramic part of the insulator and a second semicircular clamp 2 opposite to the first semicircular clamp 1 , both ends of the first semicircular clamp 1 are provided with a relatively outwardly extending first extension section 11, and both ends of the second semicircular clamp 2 are provided with a relatively outwardly extending section 11 that is in line with the first extension section. 11 parallel to the second extension section 21 , a locking device is provided between the end of the first extension section 11 and the end of the second extension section 21 . In this embodiment, the locking device includes a bolt arranged between the end of the first extension section 11 and the end of the second extension section 21, and the extended end of the bolt is provided with a lock nut, which can be locked by turning the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com