Efficient cleaning device for LED lamps

A technology of LED lights and cleaning devices, applied in the direction of cleaning methods, cleaning methods and utensils, chemical instruments and methods using gas flow, etc., can solve the problems of inability to guarantee the dust removal effect, unsatisfactory dust removal effect, and increased costs, and achieve dust removal And drying effect is better, there is no dead angle, efficient dust removal, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

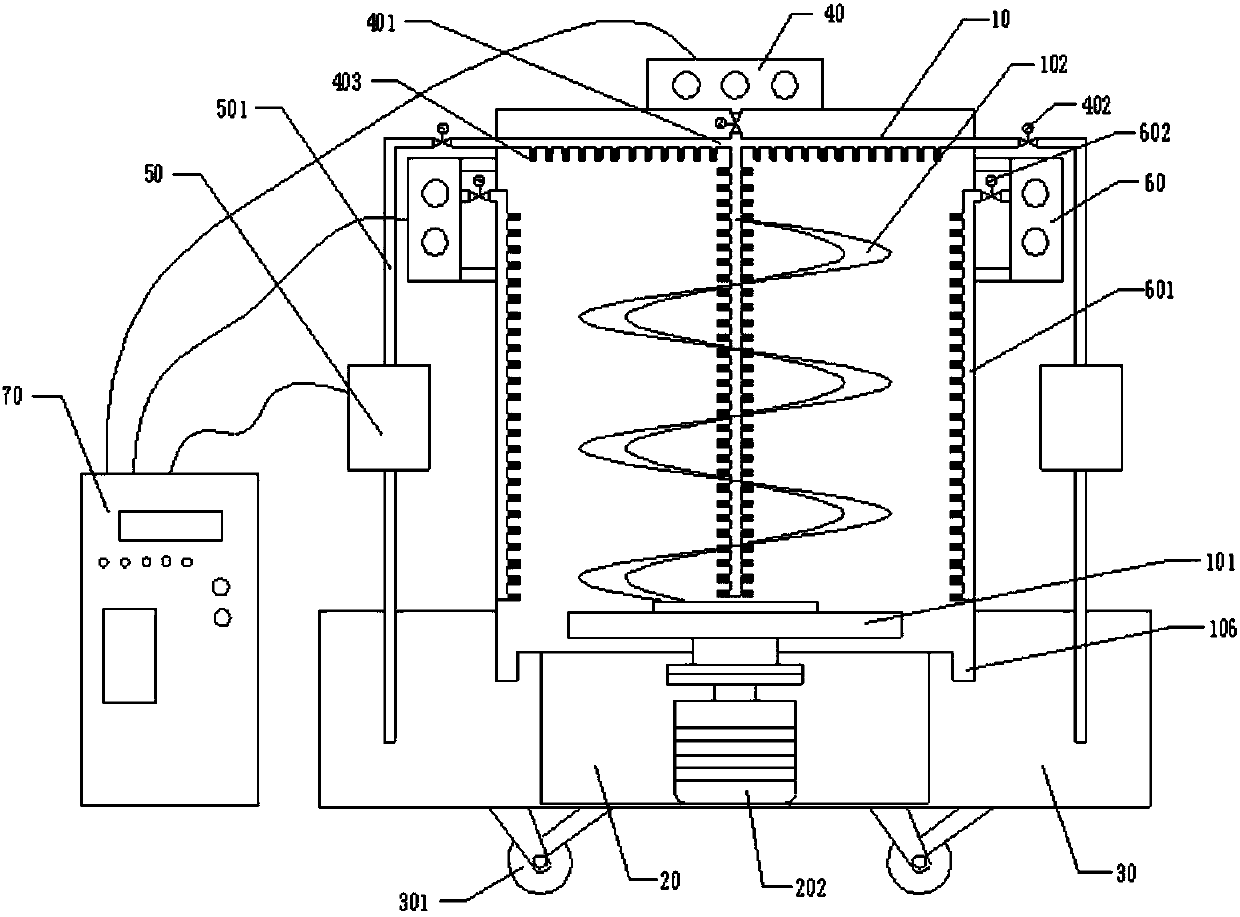

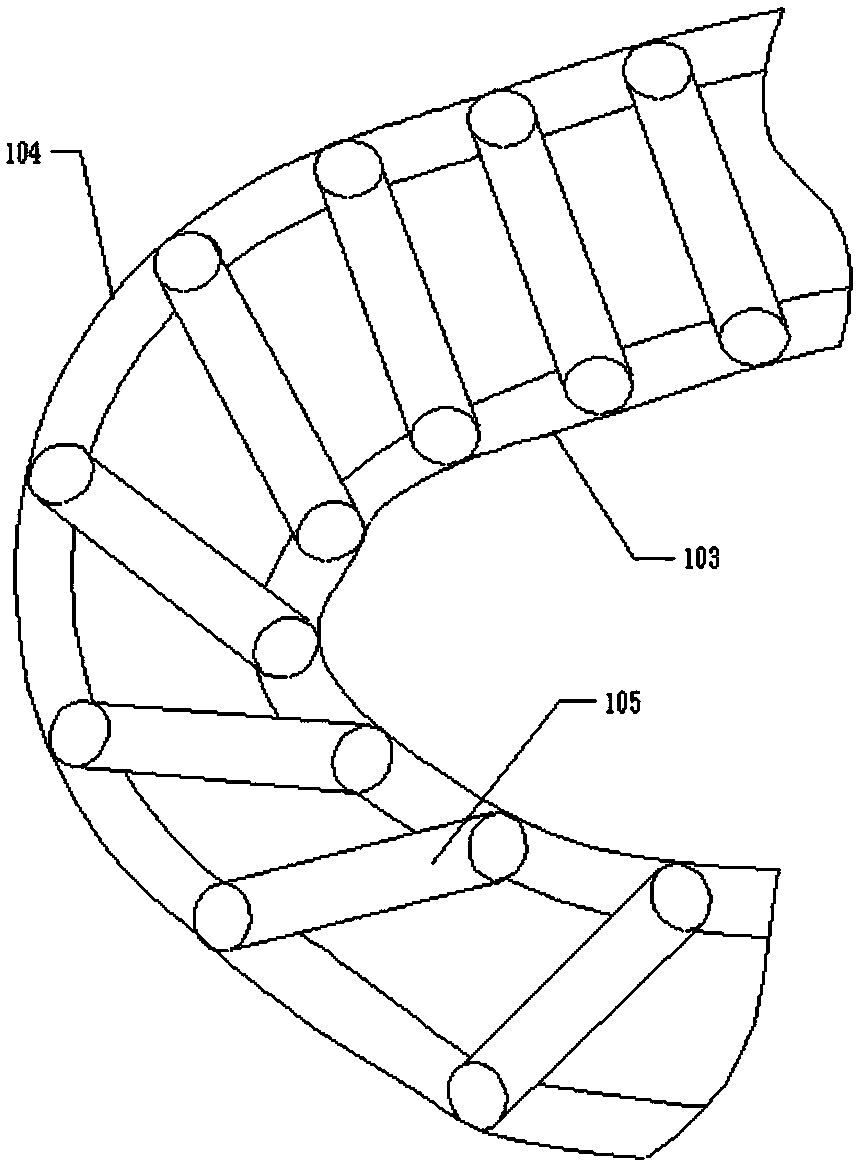

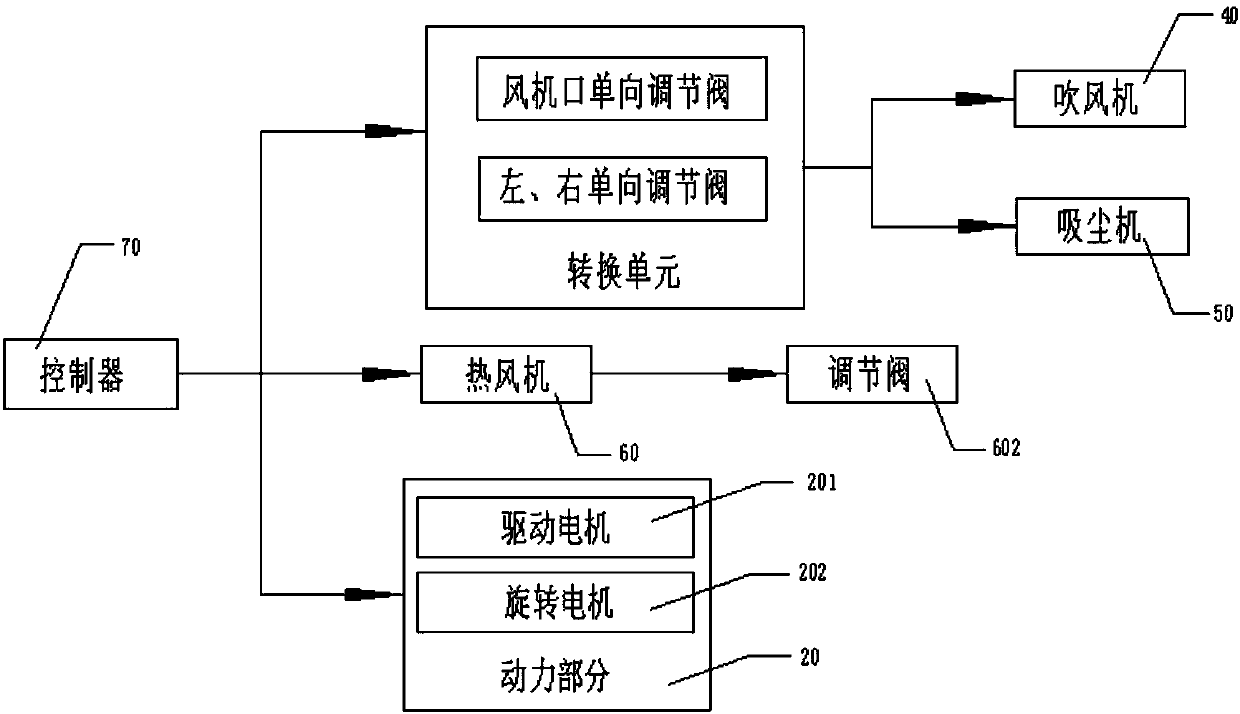

[0026] Such as Figure 1-Figure 3 As shown, a high-efficiency cleaning device for LED lamps includes a dust removal device body 10, a power part 20, a dust collection box 30, a blower 40, a vacuum cleaner 50, a hot air blower 60 and a controller 70. The bottom of the dust removal device body 10 is set The power part 20, the dust collection box 30, and the blower 40 are arranged on the top of the dust removal device body 10, and the left and right sides of the dust removal device body 10 are provided with a vacuum cleaner 50 and a hot air blower 60, and the hot air blower 60 is set to be communicated through a heat pipeline 601 The inner cavity of the dust removal device body 10, the power part 20, the blower 40, the vacuum cleaner 50 and the hot air blower 60 are all set to be electrically connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com