T-shaped three-channel reversing and automatic non-return plunger valve

A three-channel, shape-channel technology, applied in the valve field of food and beverage filling technology, can solve the problem that the valve cannot adjust the flow rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

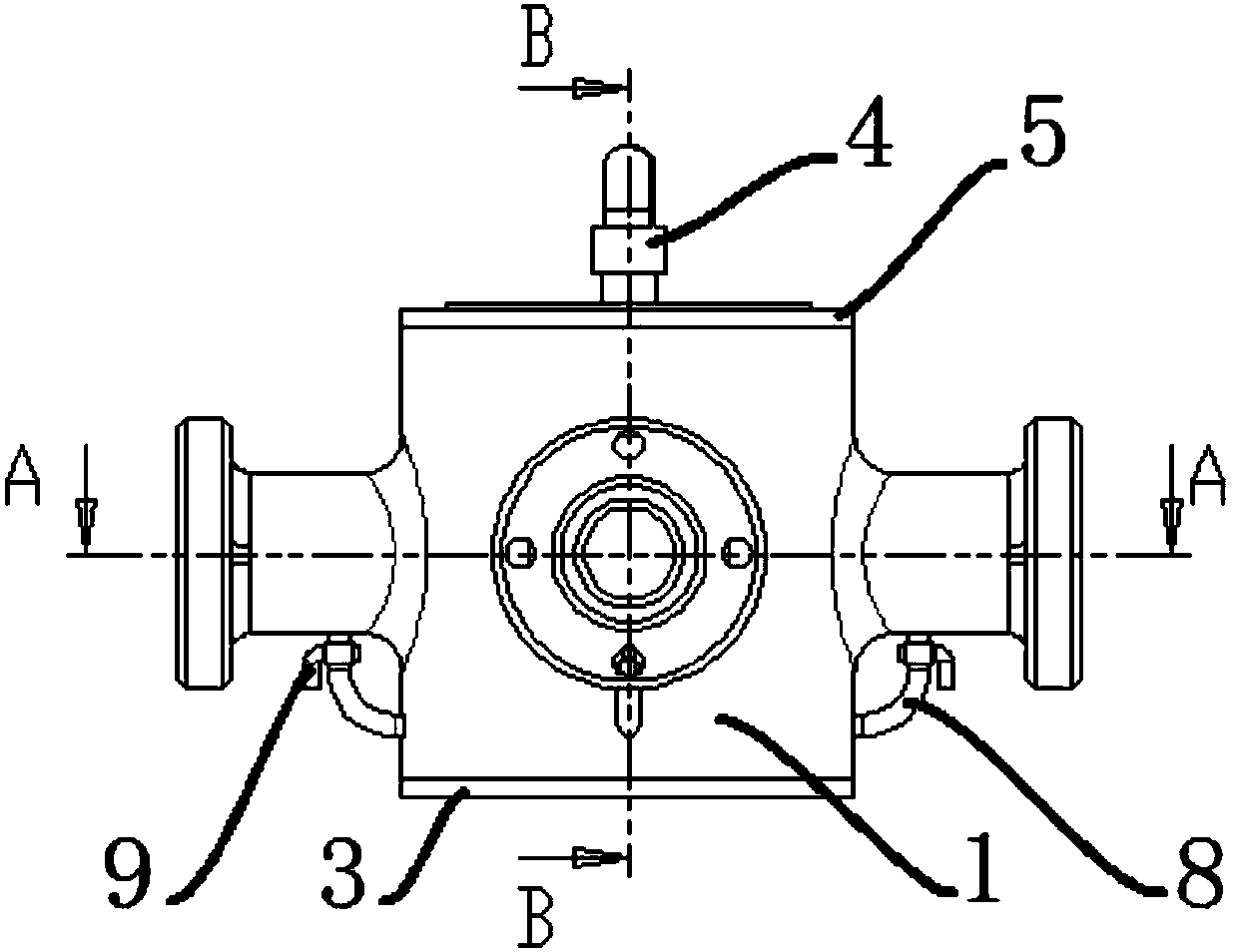

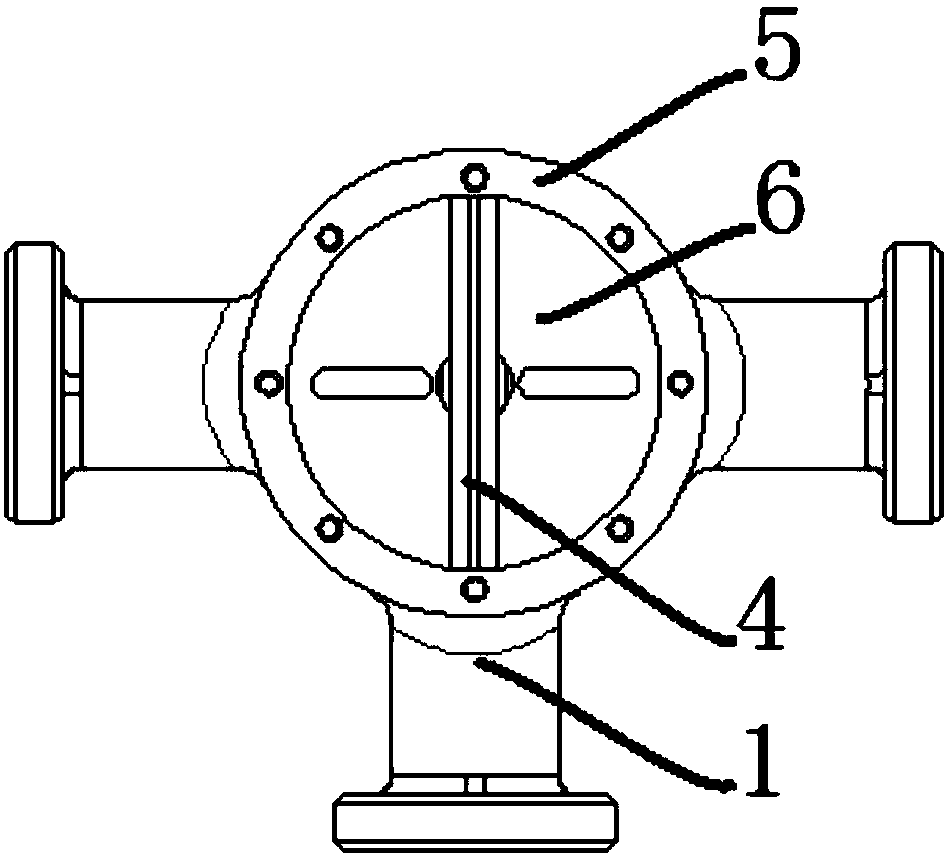

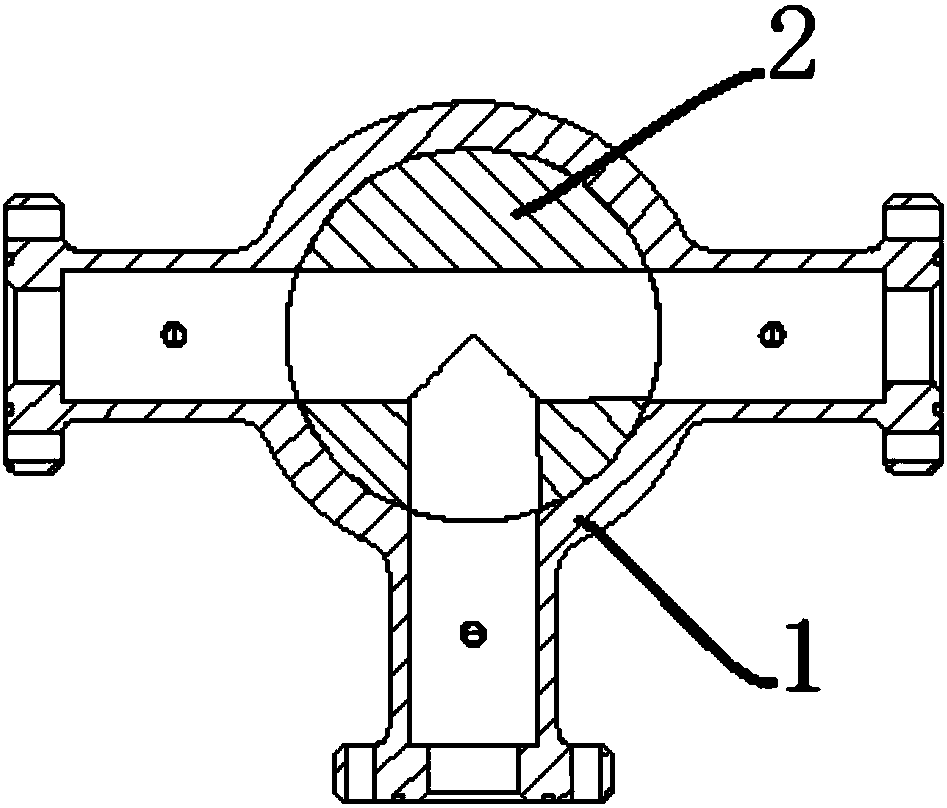

[0027] Such as Figure 1 to Figure 4 As shown, a T-shaped three-channel reversing and automatic check plunger valve of the present invention includes a valve body 1, a plunger body 2, and a valve bottom plate 3. The valve body 1 is a T-shaped three-way structure, and the valve body is respectively composed of a first The first channel, the second channel, the third channel and the cylinder body; the plunger body 2 is a cylindrical structure, the radial direction of the plunger body is provided with a T-shaped channel, and the T-shaped channels are connected to each other, and the plunger body 2 is arranged on the cylinder body Inside, the channel port of the T-shaped channel of the plunger body 2 communicates with any three or two of the first channel, the second channel, and the third channel; the valve bottom plate 3 is fixedly installed on the bottom of the valve body 1, and the valve bottom plate 3 There is a cylindrical guide sleeve on the top, a bearing rod is provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com