Two-channel stainless steel plunger valve element

A stainless steel column and plunger valve technology, which is applied in the valve field of food and beverage filling technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

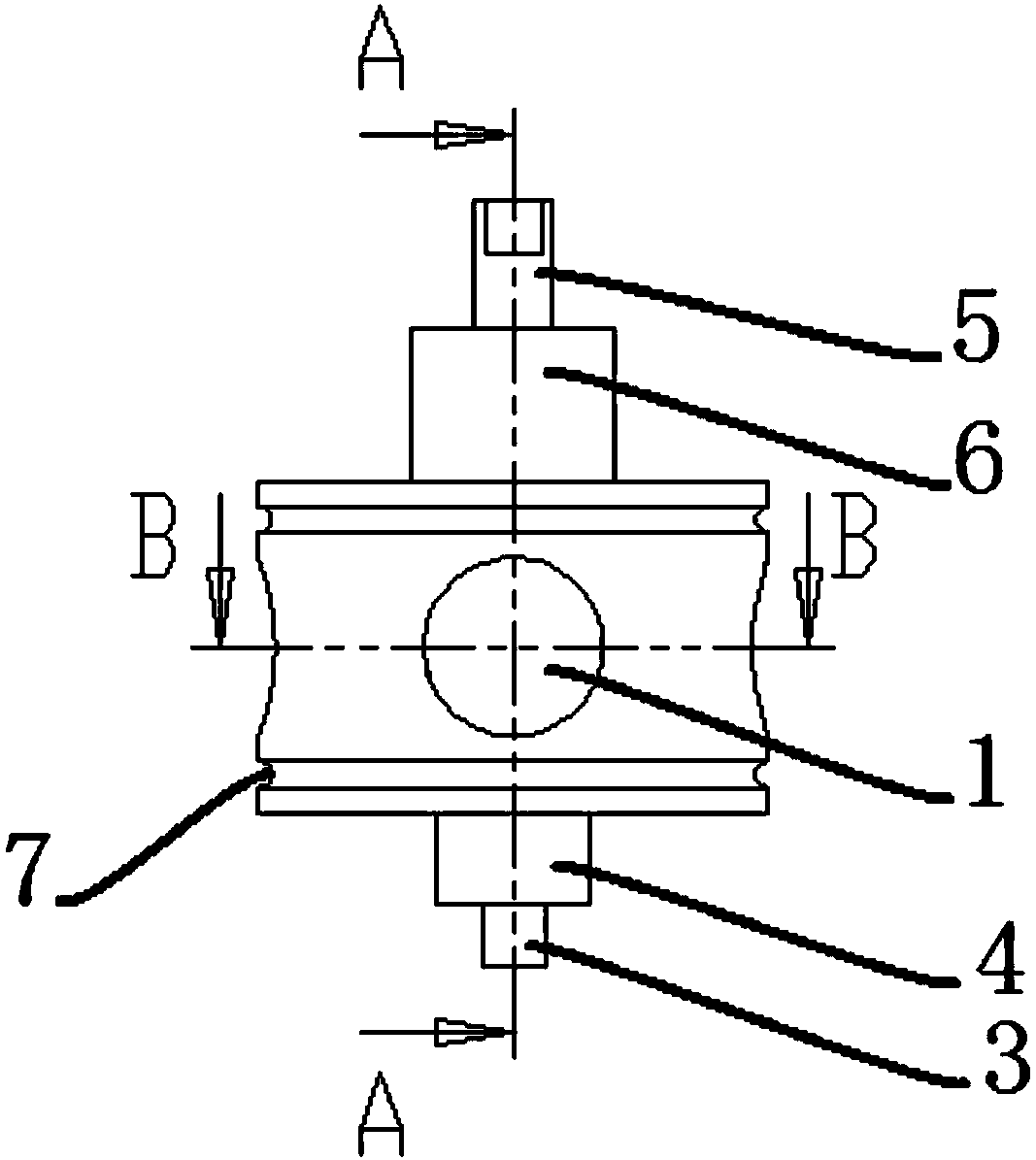

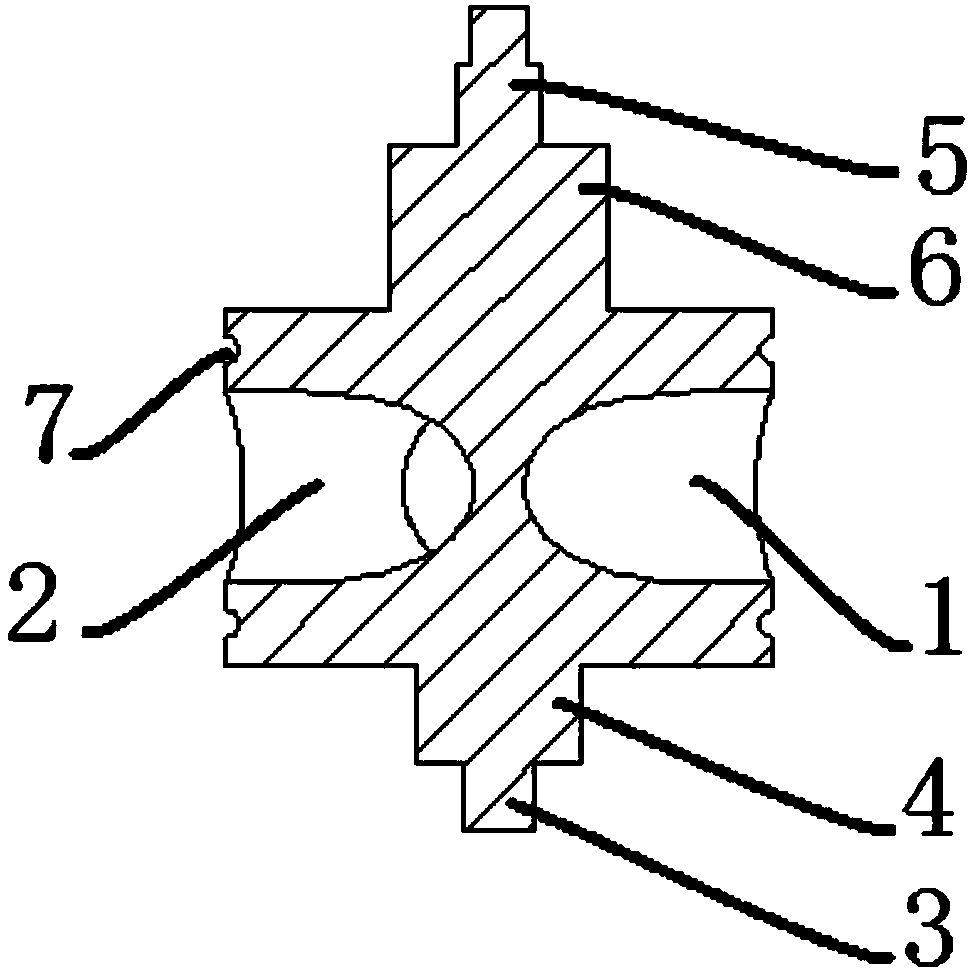

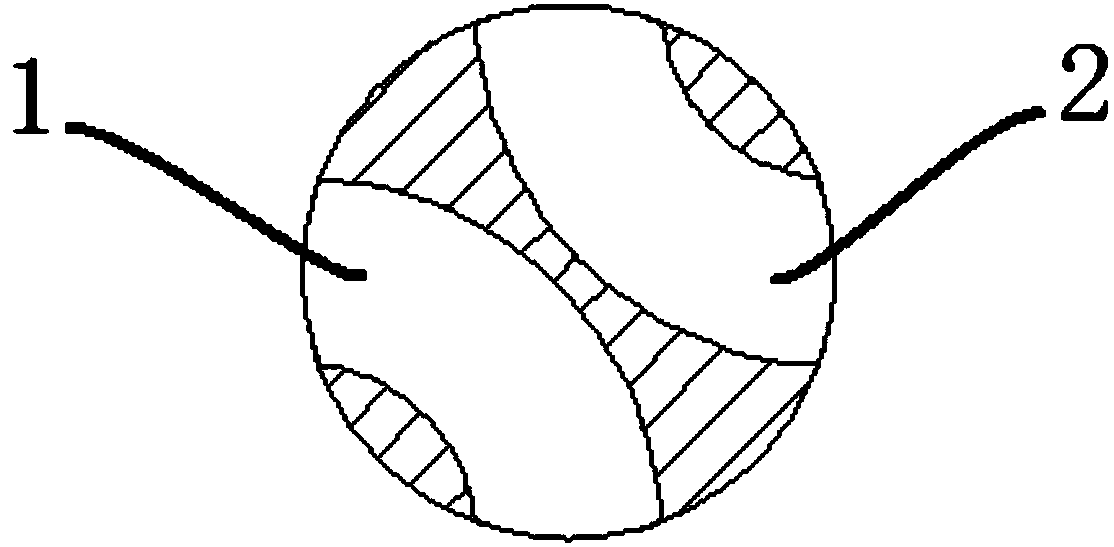

[0026] like Figure 1 to Figure 3 As shown, the present invention has a double-channel stainless steel plunger valve core, the plunger valve core is a cylindrical structure, and the radial direction of the plunger valve core is provided with a first U-shaped channel 1, a second U-shaped channel 2, and a first U-shaped channel 2. U-shaped channel 1 and the second U-shaped channel 2 are not connected. The first U-shaped channel 1 and the second U-shaped channel 2 of the plunger spool are symmetrical left and right along the center line of the plunger spool, and the channel openings of the first U-shaped channel 1 and the second U-shaped channel 2 are along the center line of the plunger spool. uniformly distributed around the circumference.

[0027] In a preferred embodiment, one end of the plunger spool is provided with a bearing rod 3, and the other end of the plunger spool is provided with a rotating shaft 5, the bearing rod 3 and the rotating shaft 5 are integrally formed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com