Auxiliary device of cable test

An auxiliary device and cable test technology, applied in the direction of the measuring device shell, fault location, clamping/spring connection, etc., can solve the problem of reducing work efficiency and rushing to repair electricity time, unstable, affecting work progress, and testing work safety test data Accuracy and other issues to achieve the effect of improving work efficiency and safety, and increasing operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

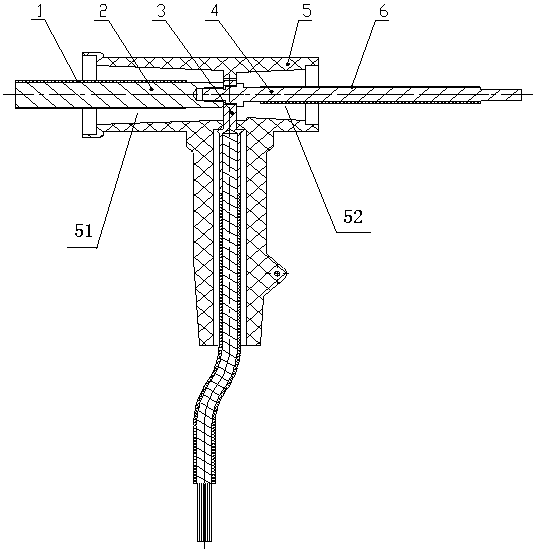

[0020] Such as figure 1 Shown is an embodiment of a 10 kV cable test auxiliary device. The auxiliary device includes a joint insulation layer 1, a threaded joint 2, a cable lug 3, an auxiliary terminal 4, a T-shaped joint 5, a terminal insulation layer 6, and a joint insulation layer 1 Wrapped on the outside of the threaded joint 2, one end of the threaded joint 2 is provided with a threaded hole 21, and the end of the cable lug 3 fits with the end of the threaded hole 21; the auxiliary terminal 4 matches the threaded hole 21; the cable lug 3 It is clamped with the T-shaped joint 5 , and the terminal insulation layer 6 is wrapped on the outside of the T-shaped joint 5 .

[0021] Wherein, the T-shaped joint 5 is provided with a first air cylinder 51 and a second air cylinder 52 , the auxiliary terminal 4 is installed on one side of the second air cylinder 52 , and the threaded joint 2 is arranged on one side of the first air cylinder 51 .

[0022] In addition, part of the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com