Waterproof and vapor permeable soles for shoes

A technology of steam and air, applied in the direction of shoe soles, footwear, applications, etc., can solve problems such as unpredictable, unreliable, and affecting final costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

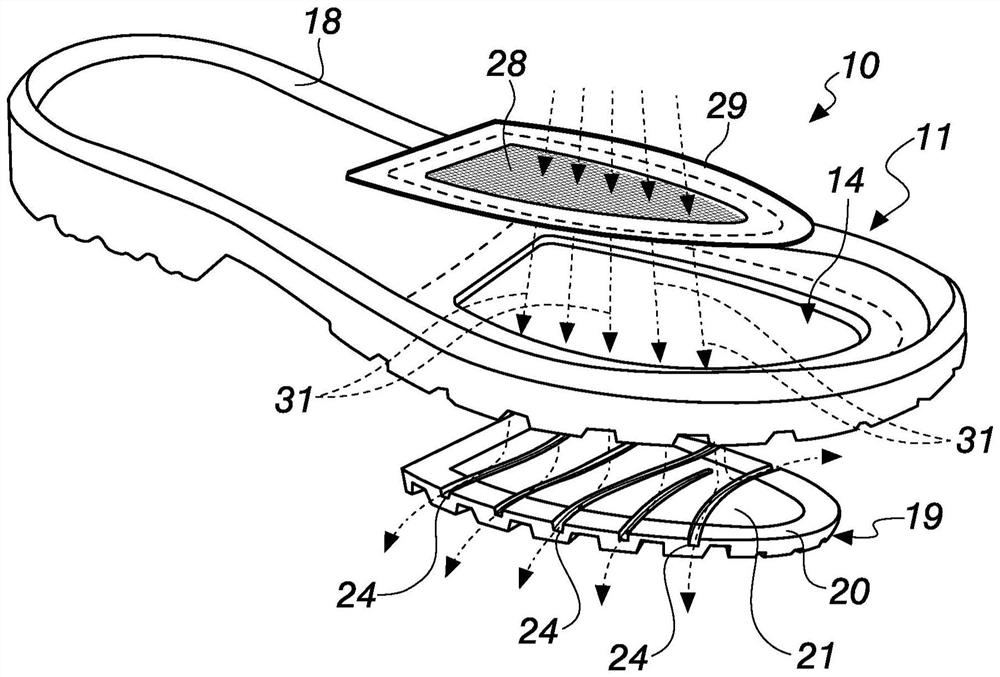

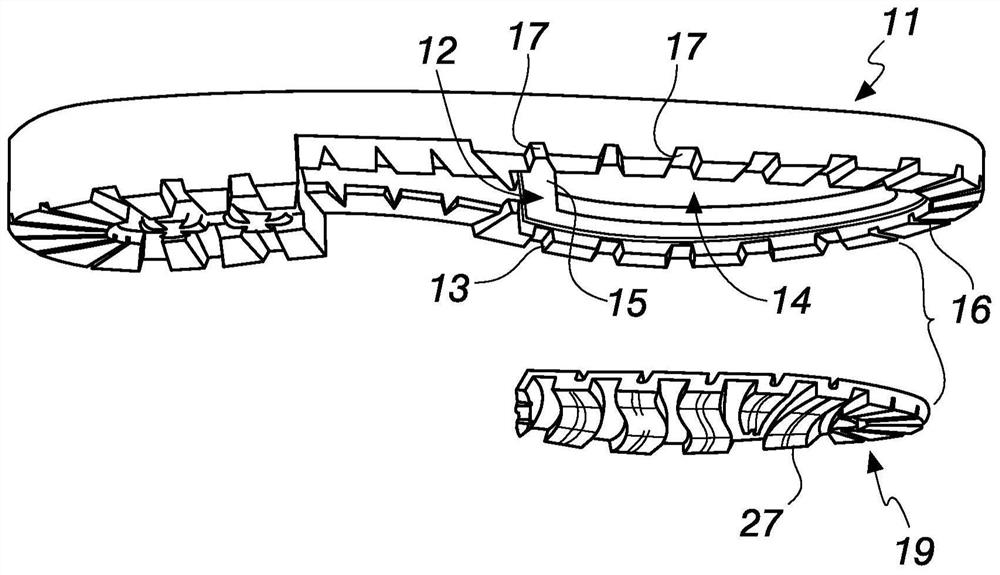

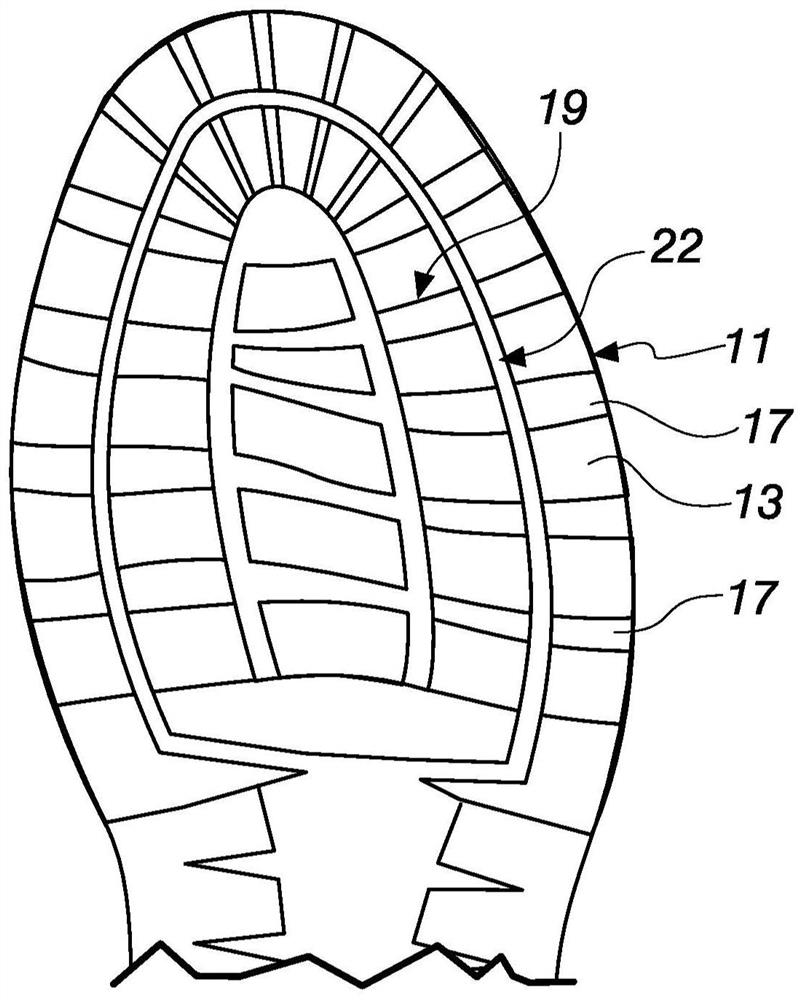

[0049] Referring to the drawings, a shoe sole according to the invention is indicated generally by the reference numeral 10 .

[0050] The sole comprises a first profiled element 11 made of polymer material having a hollow lower part 12 in the plantar area (in figure 2 shown in ), the hollow lower part 12 is delimited by a border 13 and is provided with a through-opening 14 at right angles to the ground resting structure. The through-opening 14 is in turn delimited by an inner edge 15 of the boundary 13 .

[0051] In particular, the hollow lower part 12 is located at the forefoot of the sole 10, while in the waist (i.e. middle) and heel parts, the first contoured element 11 is contoured in a known manner and in this example without other openings.

[0052]A first tread 16 for resting on the ground is integrated in the lower part with the first profiled element 11 .

[0053] The surface of the first tread 16 may be continuous, or may be interrupted in some portions thereof,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com