Screwing tool and tool holder comprising a subdivided support section

A technology of support area and support area, which is applied to the accessories of tool holders, milling cutters, manufacturing tools, etc., can solve problems such as fracture, achieve the effects of reducing friction loss, preventing overload, and improving vibration attenuation/vibration reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

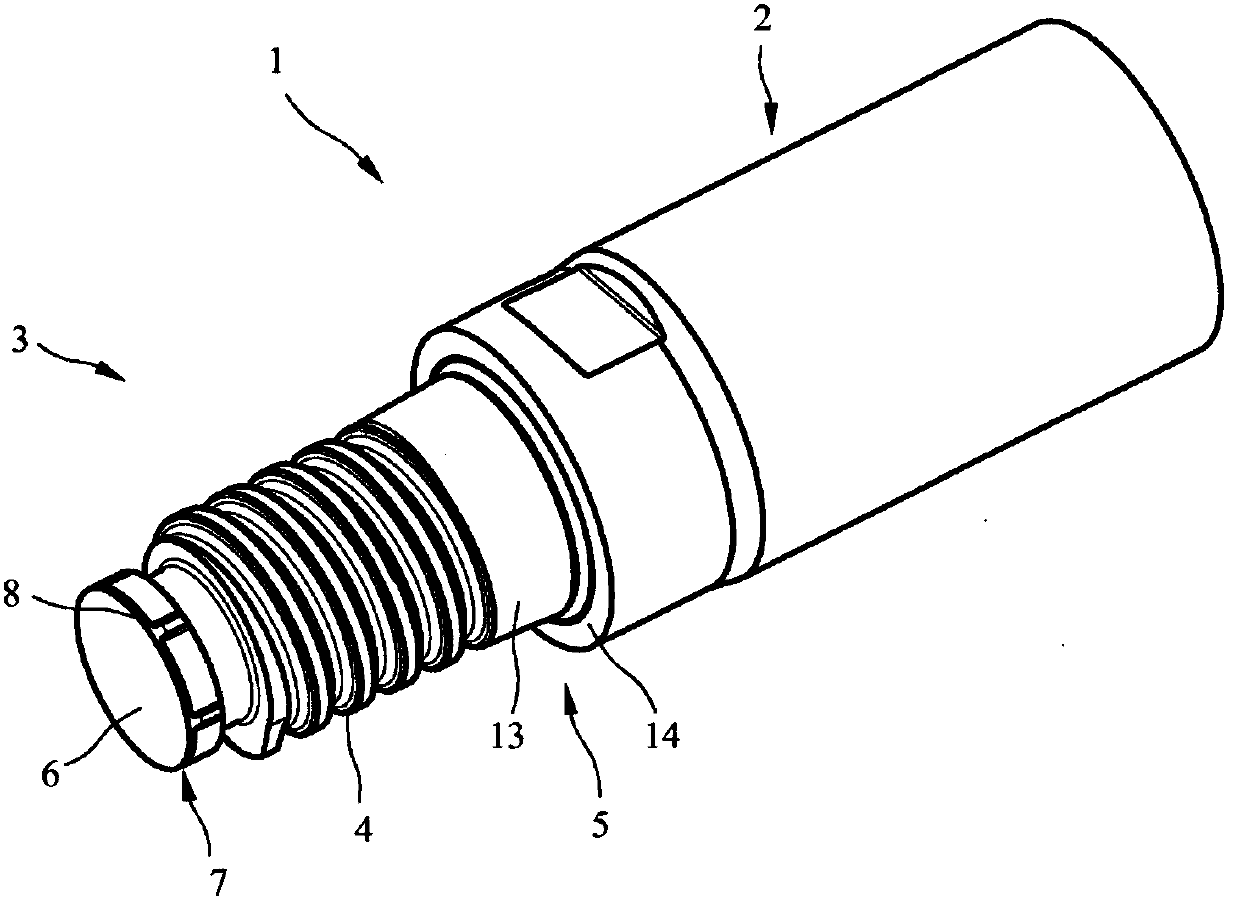

[0029] exist figure 1 shows a screw-in tool 1 with a tool head 2 and a tool shank 3 . A cutting edge (not shown) is arranged on the tool head 2 for cutting a workpiece. The tool shank 3 has an external thread 4 , a first support region 5 arranged between the tool head 2 and the external thread 4 and a second support region arranged between the free end 6 of the tool shank 3 and the external thread 4 7. The free end 6 is formed by the end face of the tool shank 3 .

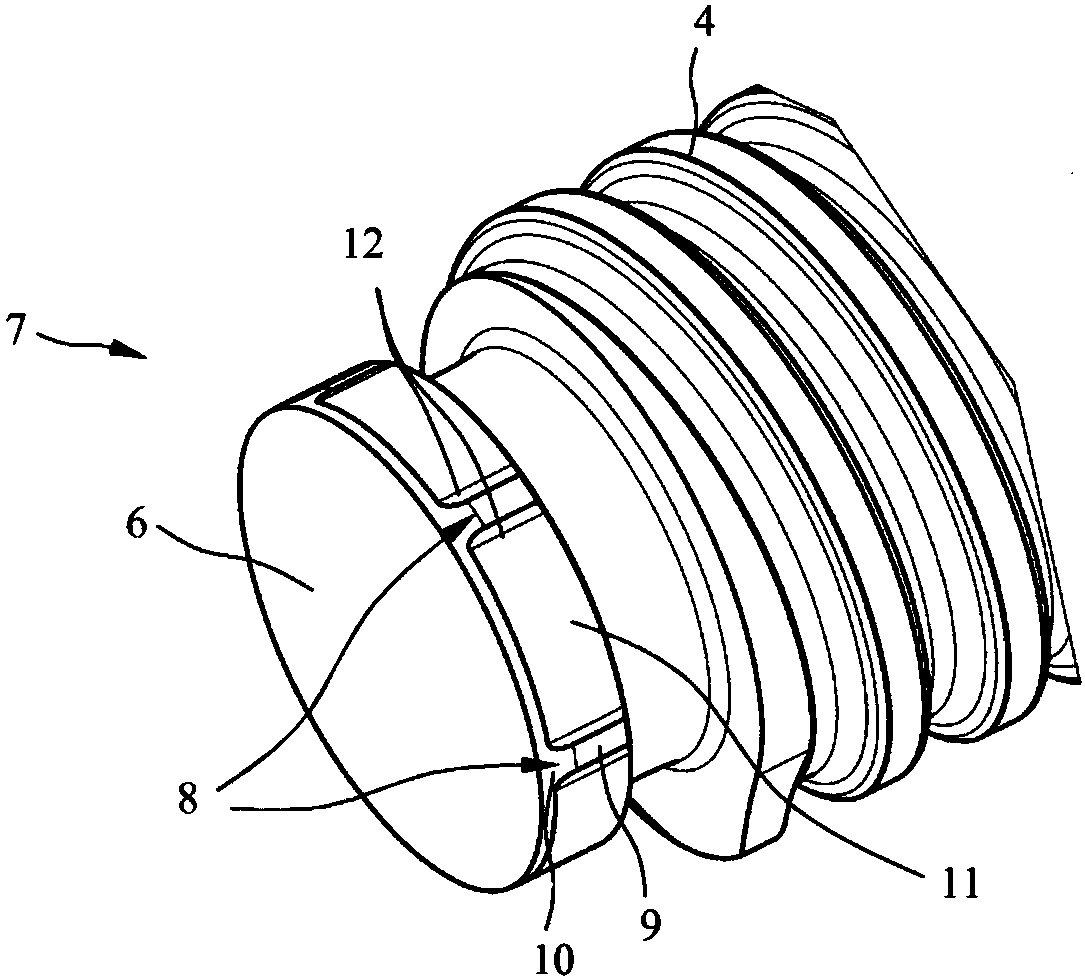

[0030] The first support region 7 has support elements 8 spaced apart from one another in the circumferential direction and projecting radially outward. refer to figure 2 The configuration of the support member 8 is described in detail.

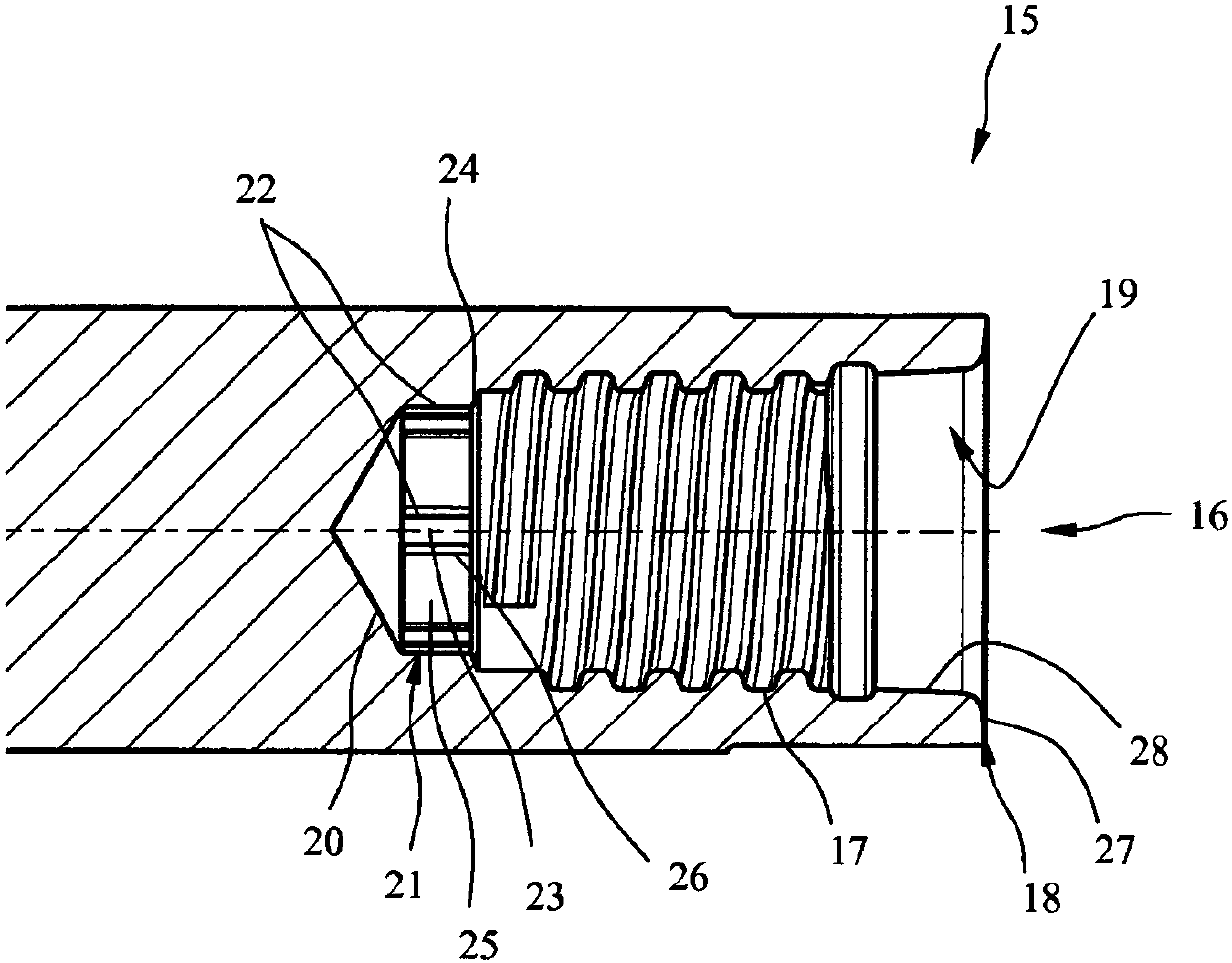

[0031] exist figure 2 shown in detail in figure 1 The second support area 7 of the screw-in tool 1. As can be seen in the figure, the support elements 8 are designed as webs extending in the axial direction of the screw-in tool 1 and spaced evenly from one another. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com