Hoisting winch assembly

A hoisting winch and component technology, which is applied to cranes, trolleys, transportation and packaging, etc., can solve the problems of expensive assembly and difficult layout of the hoisting winch system, and achieve low weight, less sealing points, and less compensation couplings. effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

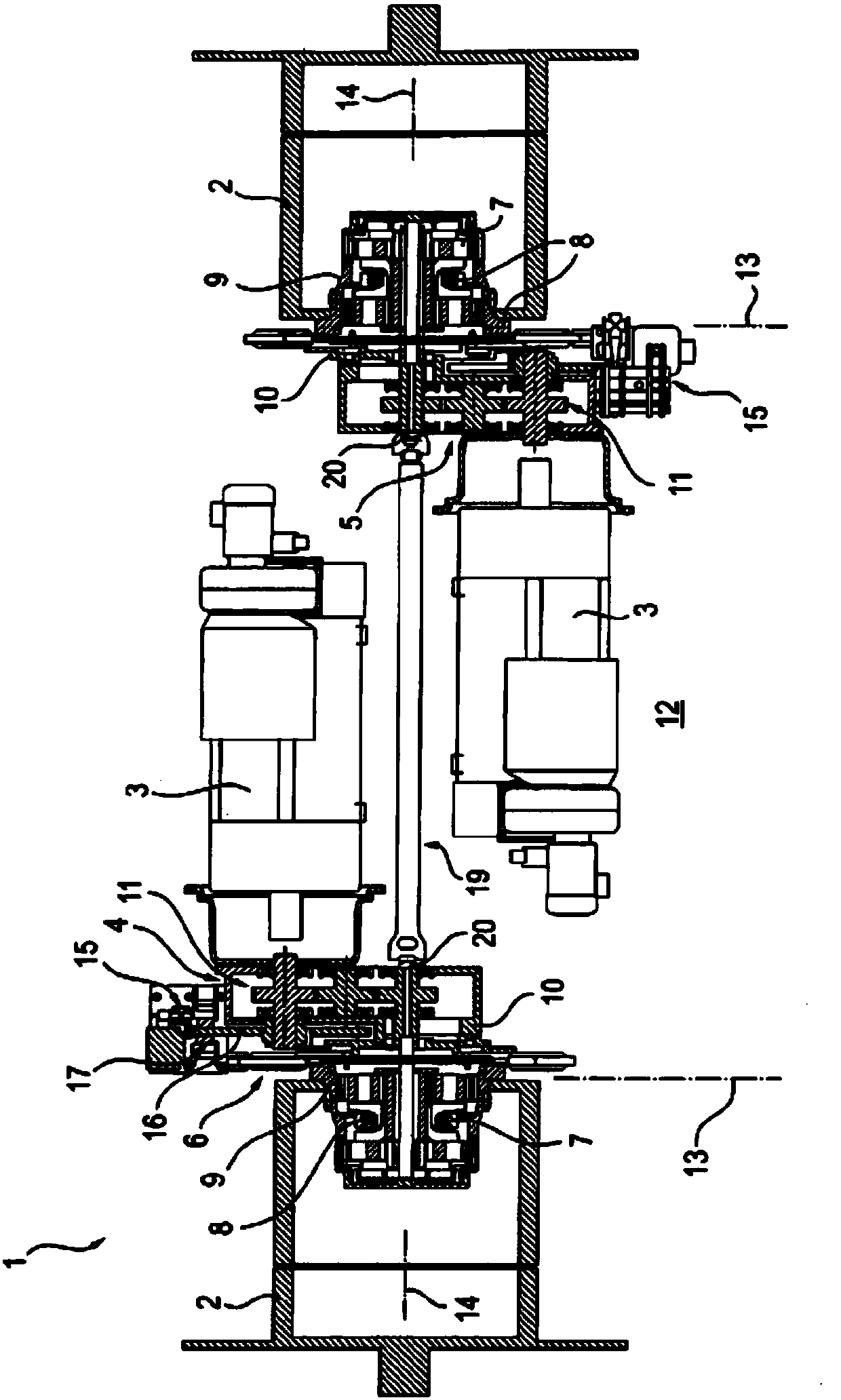

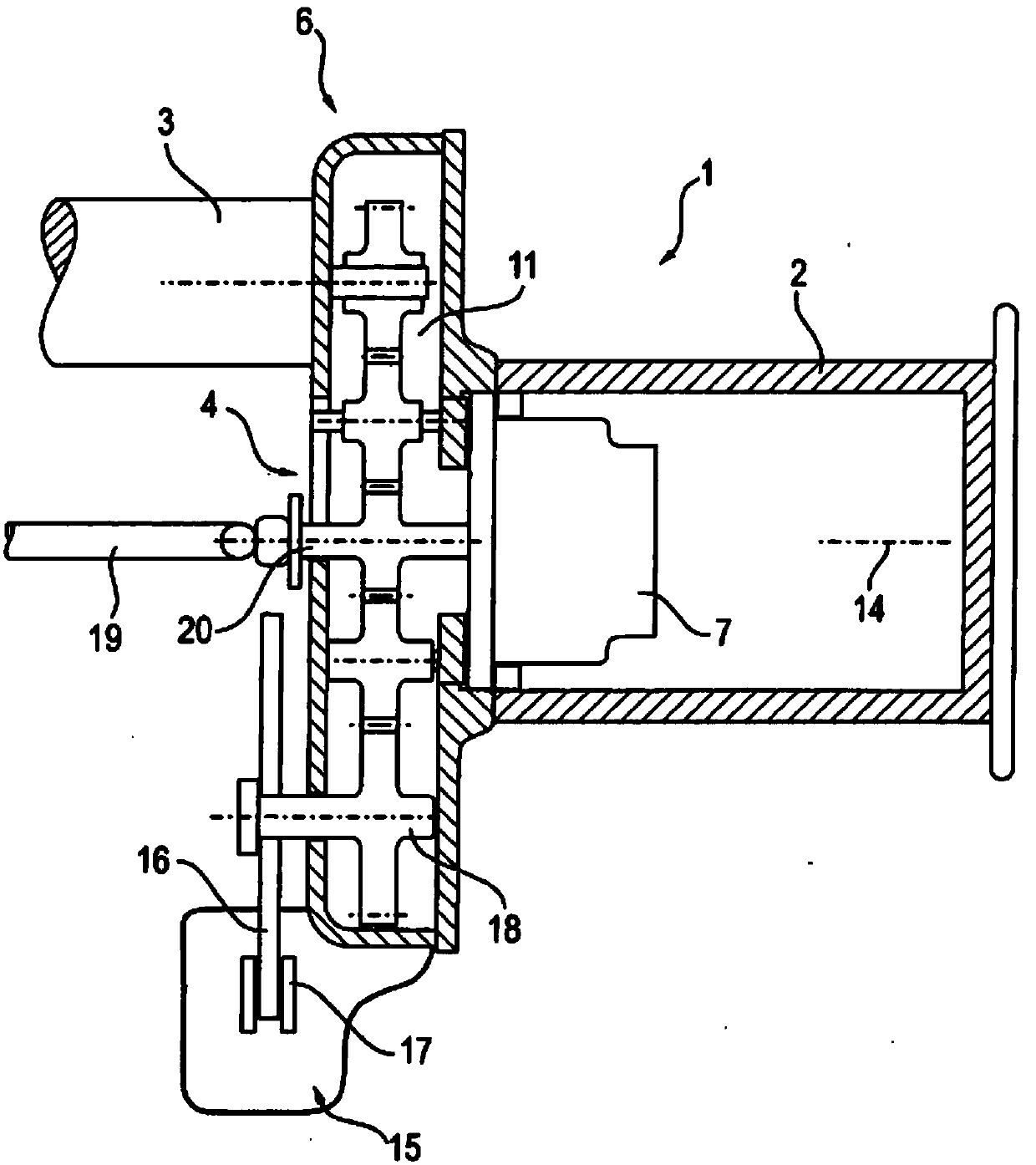

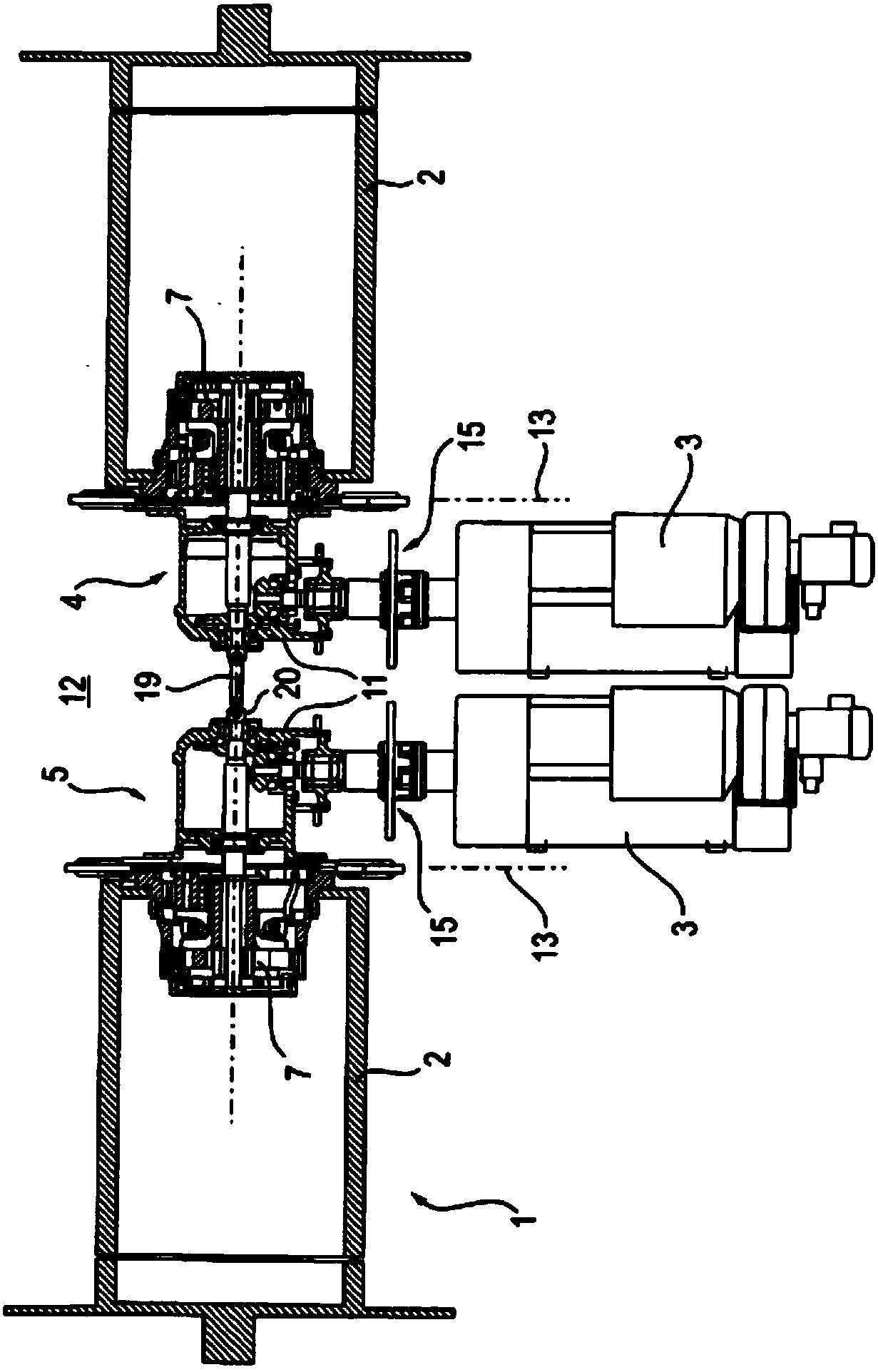

[0026] As shown in the figures, the hoisting winch assembly 1 comprises two axially parallel drums 2 spaced apart from each other, which drums can be constructed in the usual manner per se with respect to their basic structure, and can in particular consist of flanged wheels with grooves. Roller body. On the edge portion of the end face, the drum 2 may also comprise a non-grooved cylindrical portion forming a reserve if longer ropes are to be pulled up. In a manner known per se, in order to be able to stably raise and lower the lifting spreader for picking up the containers, two ropes can be drawn from each drum 2 , as can be the case, for example, in gantry cranes or container cranes .

[0027] As shown, in particular, the drums 2 may be arranged coaxially with each other.

[0028] Each drum 2 here is driven by an electric motor 3 , and the motor 3 is drivingly connected to only one drum respectively via a separate gear transmission mechanism 4 or 5 of a transmission assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com