Lifting winch components

一种起重绞车、组件的技术,应用在起重机、小车的起重机、卷扬装置等方向,能够解决布置难题、起重绞车系统组装昂贵等问题,达到小重量、少密封点、少抗摩擦轴承的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

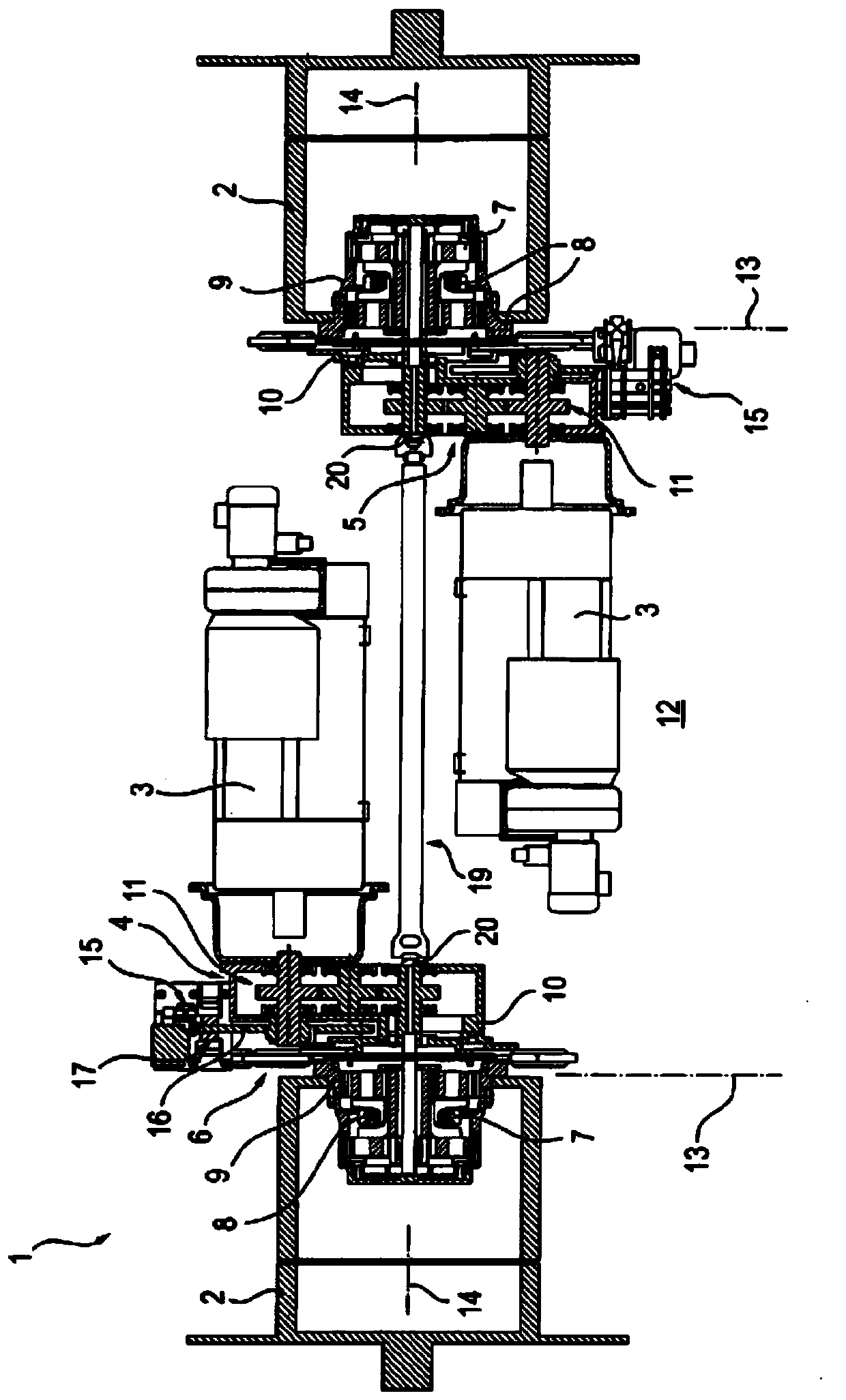

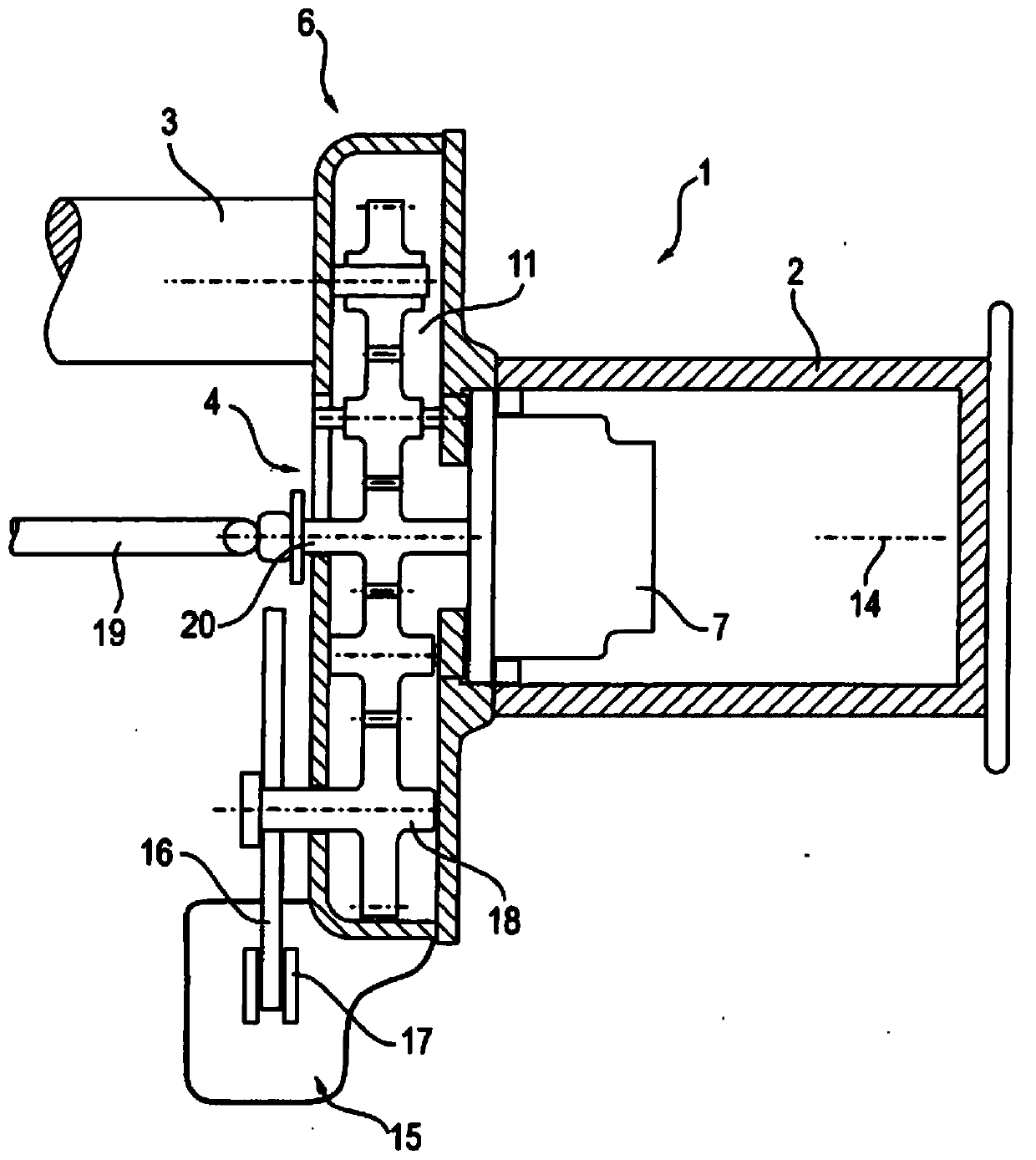

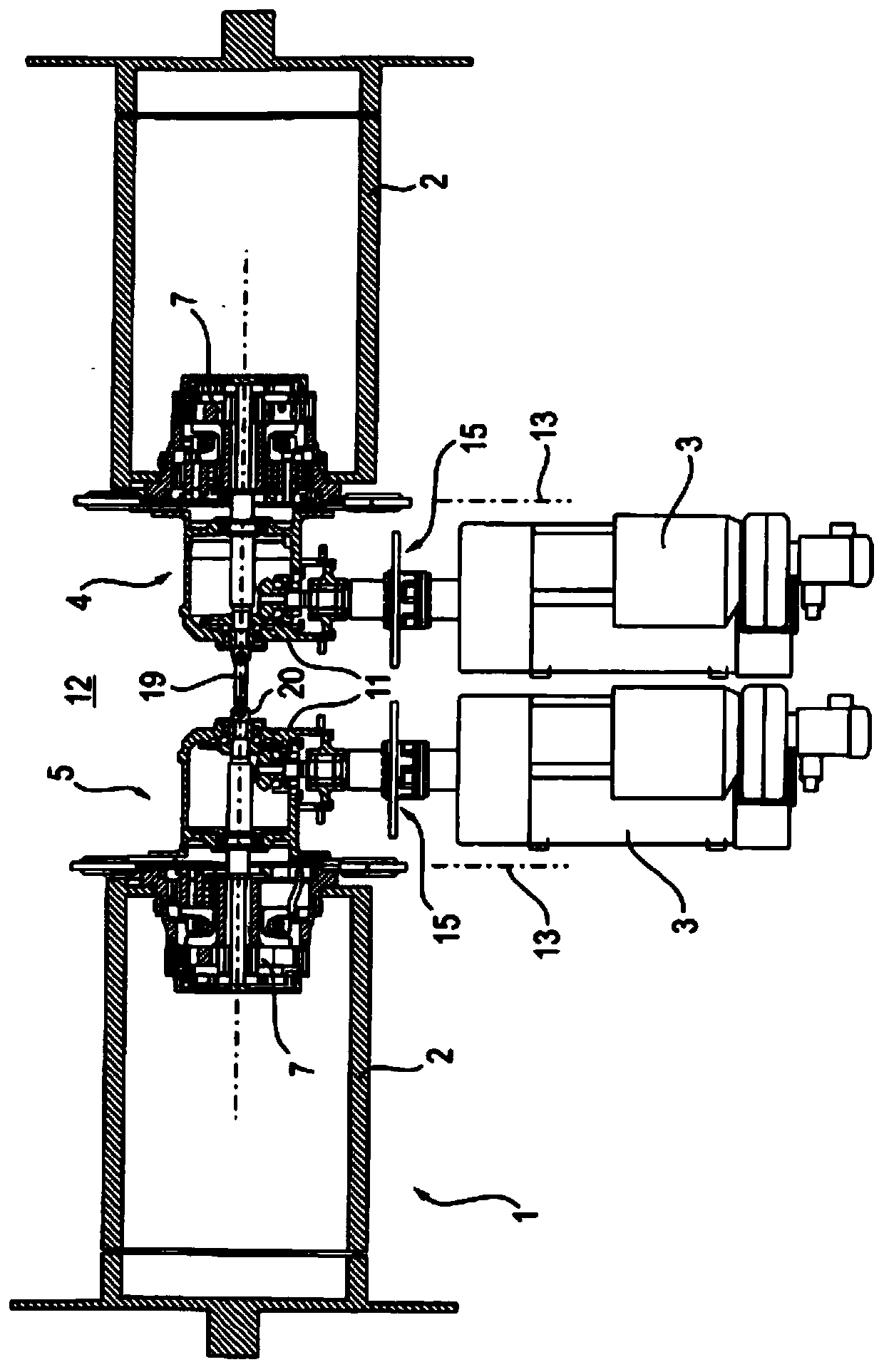

[0026] As shown in the figures, the hoisting winch assembly 1 comprises two axially parallel drums 2 spaced apart from each other, which drums can be constructed in the usual manner per se with respect to their basic structure, and can in particular consist of flanged wheels with grooves. Roller body. On the edge portion of the end face, the drum 2 may also comprise a non-grooved cylindrical portion forming a reserve if longer ropes are to be pulled up. In a manner known per se, in order to be able to stably raise and lower the lifting spreader for picking up the containers, two ropes can be drawn from each drum 2 , as can be the case, for example, in gantry cranes or container cranes .

[0027] As shown, in particular, the drums 2 may be arranged coaxially with each other.

[0028] Each drum 2 here is driven by an electric motor 3 , and the motor 3 is drivingly connected to only one drum respectively via a separate gear transmission mechanism 4 or 5 of a transmission assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com