Thin-walled tube weld joint ultrasonic detection device

A technology for inspection devices and thin-walled pipes, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc. Poor, difficult ultrasonic inspection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

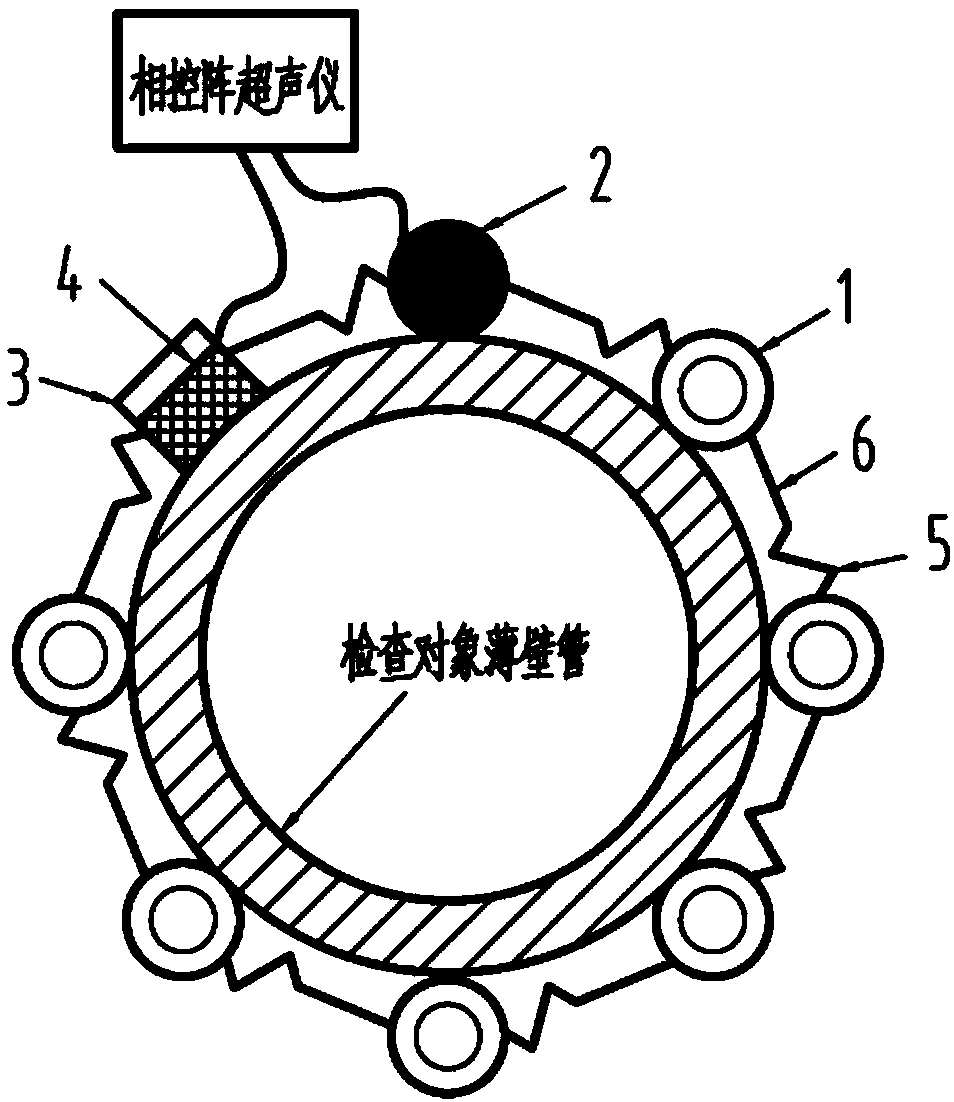

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

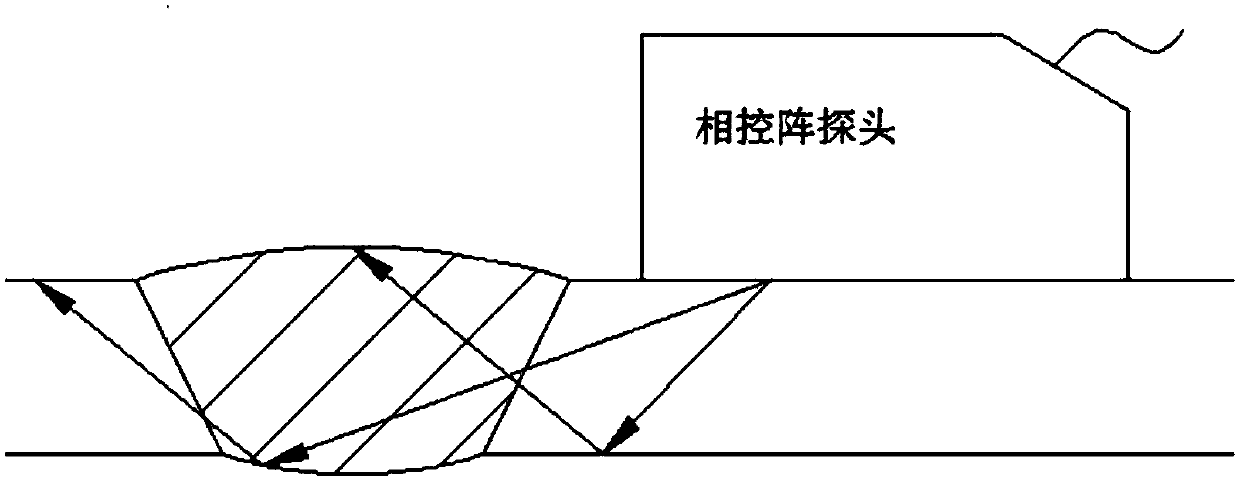

[0026] Phased array ultrasound (PA) is an advanced method. The piezoelectric wafer in the phased array probe is replaced and excited according to a selected sequence. Yes, electronic scanning (E-scan) can complete high-precision and rapid cross-sectional scanning (Sector S-scan), A-scan, rolling B-scan and L (linear) scan, and even C-scan can be completed. The ultrasonic beam can cover the component very quickly, and its detection efficiency is extremely efficient. The probe can complete multi-viewpoint scanning. One The probe can replace multiple previous probes with different angles and different focal points, thus greatly shortening the inspection time.

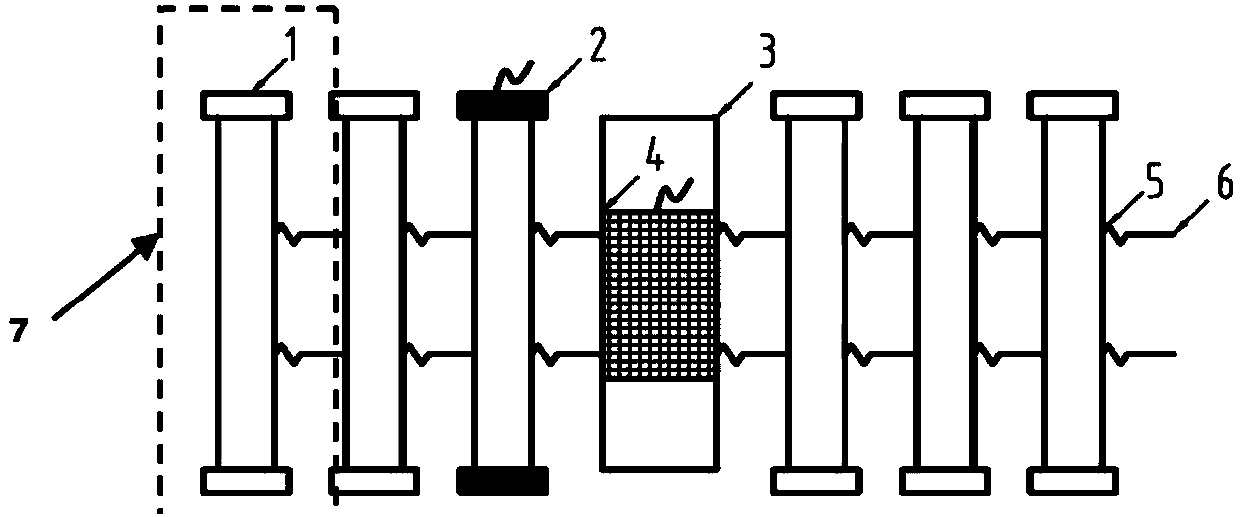

[0027] Based on the characteristics of phased array probe inspection, a crawler-type circumferential track can be designed, carrying phased array probes to carry out axial scannin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com