Passive automatic antifoam delivery system for use with single-use bioreactors

A technology of bioreactor and defoamer, which is applied in specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, biochemical instrument, etc., can solve problems such as system controller failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present disclosure is generally directed to using antifoaming agent devices and methods in order to improve the use of bioreactor bags. As will be appreciated, the various diagrams, flowcharts, and scenarios described herein are examples only, and that there are many other scenarios to which the present disclosure will apply.

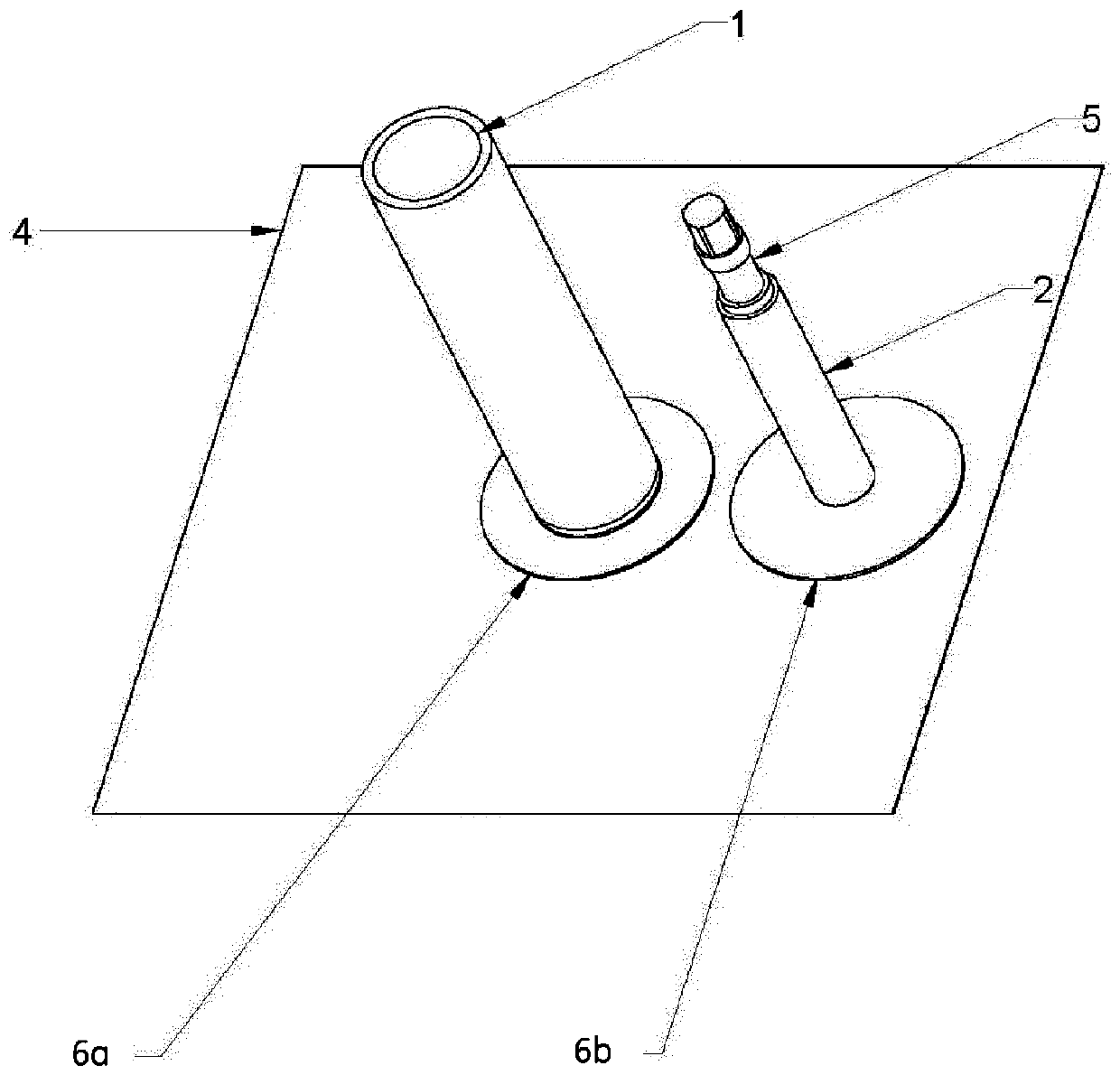

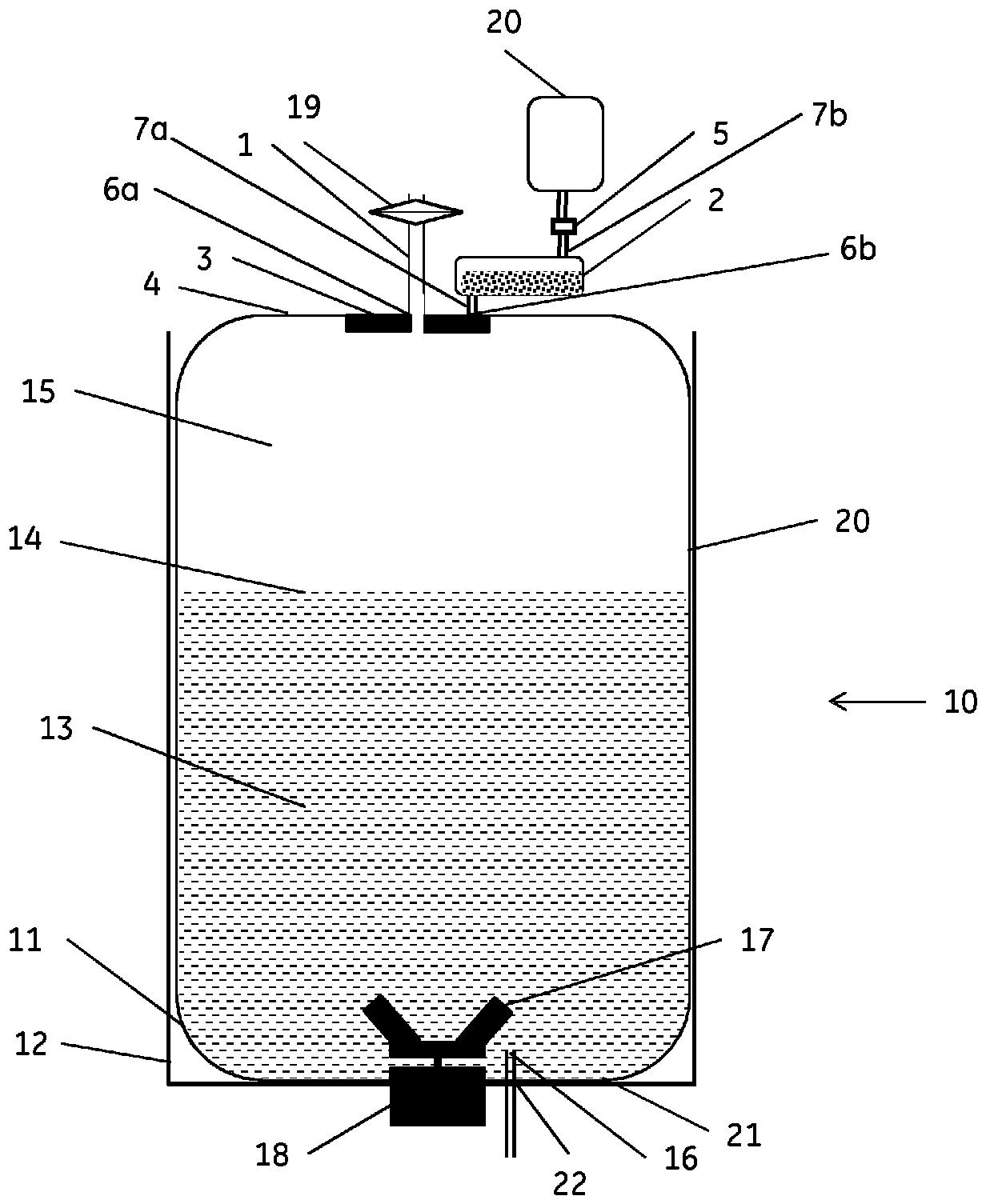

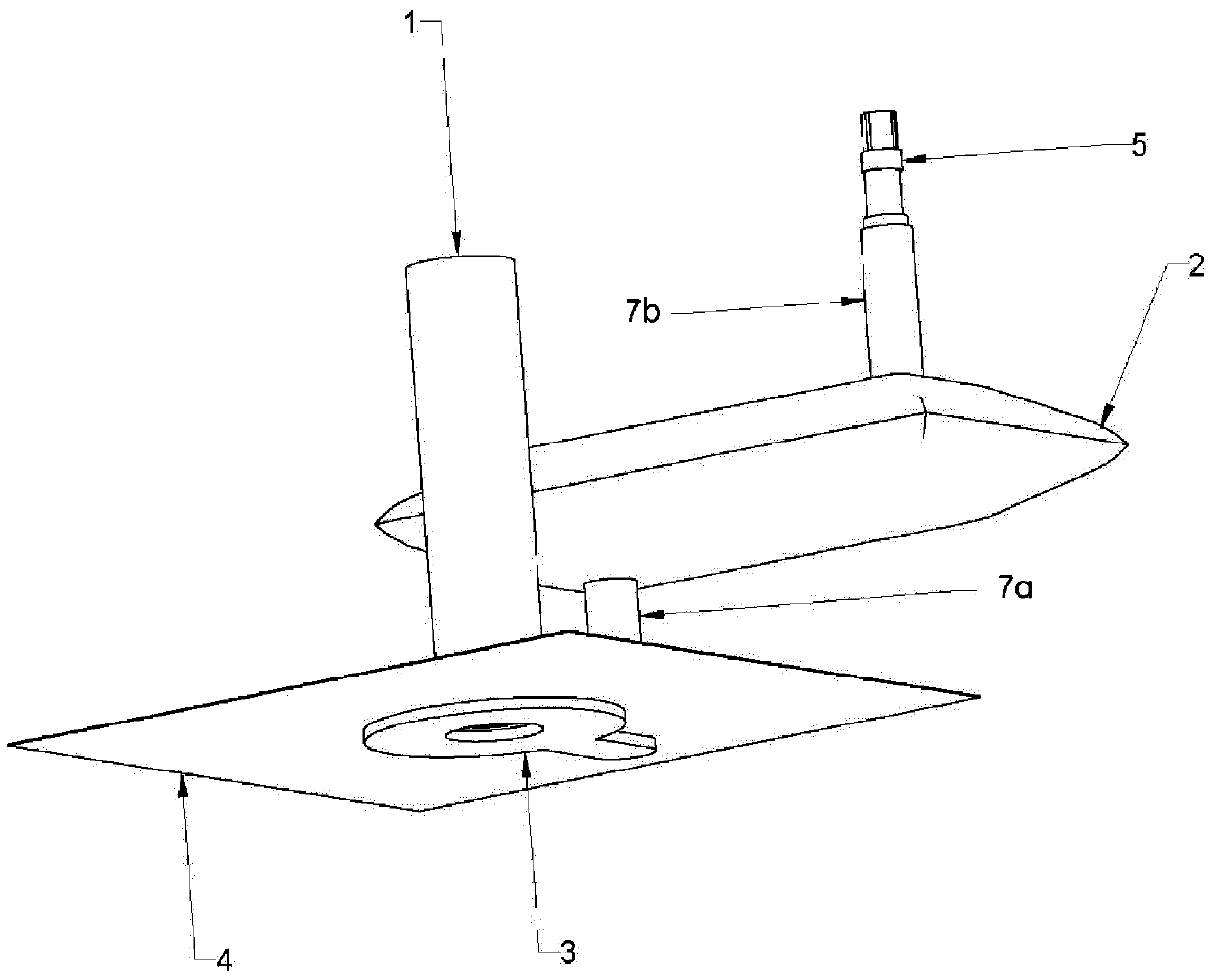

[0042] see figure 1 , figure 2 and Figure 7 , showing two embodiments of passive defoamer systems. In these figures, the exhaust gas outflow pipe 1 is shown connected to a section of the bioreactor bag wall 4 via a port fitting 6 a which can be heat welded to the bag membrane 4 . The tube can be made from one of many materials commonly used in the pharmaceutical industry such as platinum cured silicon or C-Flex. Tubes may be flexible, semi-rigid or rigid. There may be one or more exhaust gas outflow tubes attached to the bioreactor bag 11 . The other end of each exhaust pipe may be connected to a condenser (not shown), an exhaust filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com