Particulate matter sensor with engineered particle size cut-off point

A technology of particulate matter and sensor, which can be used in the separation of dispersed particles, filtration of dispersed particles, instruments, etc., and can solve problems such as increasing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

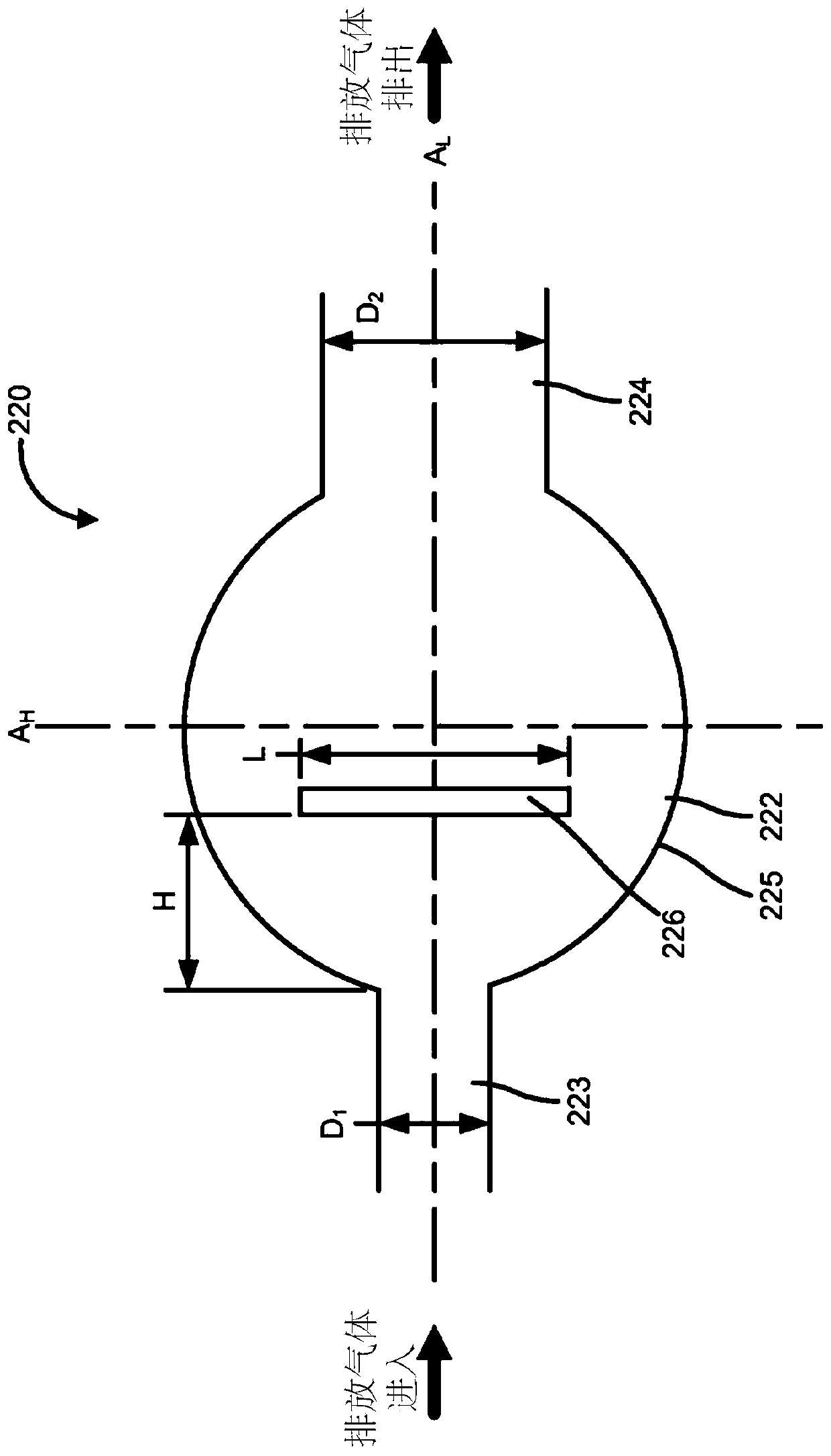

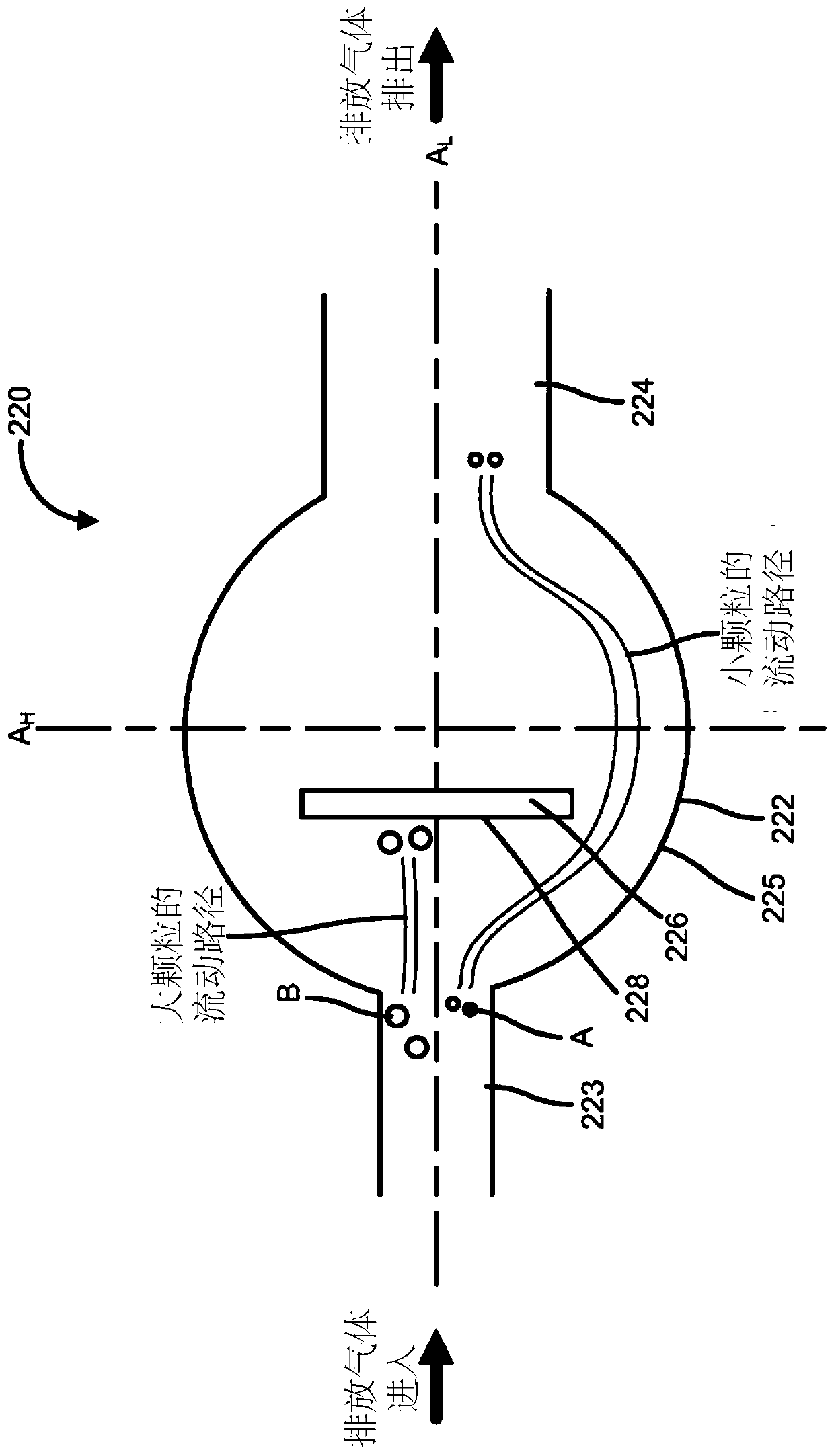

[0020] Embodiments described herein relate generally to systems and methods for detecting failure of a particulate filter of an aftertreatment system using a PM sensor assembly. In various embodiments, the systems and methods described herein include a PM sensor assembly including a PM sensor within a housing. The housing is configured to redirect the flow of exhaust gas entering the housing so that only large particles having a size greater than a predetermined size range (corresponding to a minimum effective filter size range of the particulate filter) impinge on and accumulate on the PM sensor. This accumulation causes changes in the electrical parameters of the PM sensor to indicate a malfunction of the particulate filter.

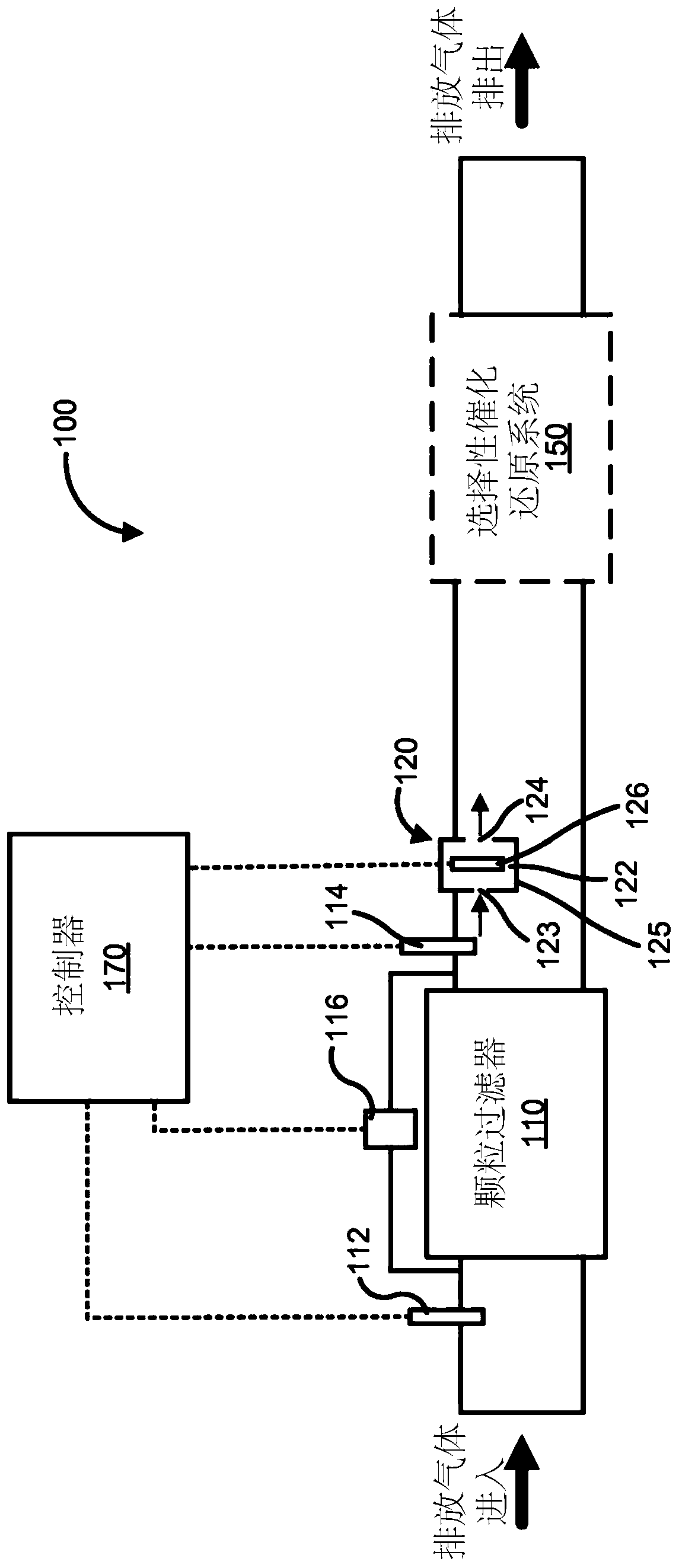

[0021] Conventional aftertreatment systems typically include particulate filters (such as figure 1 PM sensor downstream of the particulate filter 110). The PM sensor generally includes an accumulation type sensor that allows particles included in PM ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap