Multi-ridge multipurpose ponding machine

A rack and conveyor belt technology, applied in the field of multi-ridge and multi-purpose pond making machines, can solve the problems of multiple groups of manpower, time-consuming and labor-intensive, and achieve the effects of avoiding splashing and hurting people, fast sliding speed, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

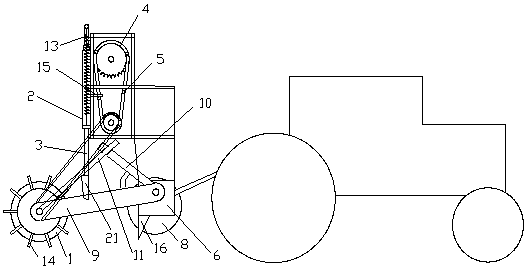

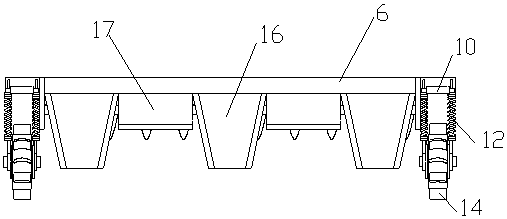

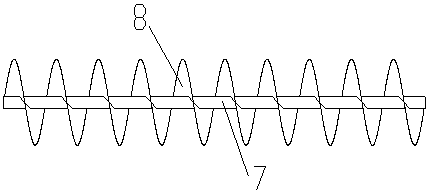

[0028] Ridge is multi-purpose pond making machine, is pulled by traction equipment, comprises soil loosening mechanism, sub-ridge plate 16, walking wheel 1, pond making mechanism, described loosening mechanism comprises frame 6, rotating shaft 7, and described rotating shaft 7 two ends and The frame 6 is connected, and the rotating shaft 7 is provided with a soil turning blade 8, and the rotating shaft 7 is driven by the power device. Along the forward direction, the dividing ridge plate 16 is arranged at the rear of the loosening mechanism. The number of the dividing ridge plates 16 is three, and the machine The frame 6 is evenly distributed from one end to the other;

[0029] Described traveling wheel 1 is arranged on frame 6 both sides, and the gap between described pond-making mechanism corresponding dividing ridge plate 16 is installed in the rear of soil loosening mechanism; Pond-beating bar 3 and conveyor belt 4 in the slide rail 2; described conveyor belt 4 is provided...

Embodiment 2

[0032] Ridge is multi-purpose pond making machine, is pulled by traction equipment, comprises soil loosening mechanism, sub-ridge plate 16, walking wheel 1, pond making mechanism, described loosening mechanism comprises frame 6, rotating shaft 7, and described rotating shaft 7 two ends and The frame 6 is connected, and the rotating shaft 7 is provided with a soil turning blade 8, and the rotating shaft 7 is driven by the power device. Along the forward direction, the dividing ridge plate 16 is arranged at the rear of the loosening mechanism. The number of the dividing ridge plates 16 is three, and the machine The frame 6 is evenly distributed from one end to the other end; the frame 6 between the adjacent described rib-dividing plates 16 is provided with a caressing plate 17, and the bottom end of the caressing plate 17 is higher than the rib-dividing plate 16 bottom. Smoothing the top of the ridge formed by the smoothing plate 17 is convenient for making ponds and farming in t...

Embodiment 3

[0036]Ridge is multi-purpose pond making machine, is pulled by traction equipment, comprises soil loosening mechanism, sub-ridge plate 16, walking wheel 1, pond making mechanism, described loosening mechanism comprises frame 6, rotating shaft 7, and described rotating shaft 7 two ends and The frame 6 is connected, and the rotating shaft 7 is provided with a soil turning blade 8, and the rotating shaft 7 is driven by the power device. Along the forward direction, the dividing ridge plate 16 is arranged at the rear of the loosening mechanism. The number of the dividing ridge plates 16 is three, and the machine The frame 6 is evenly distributed from one end to the other end; the frame 6 between the adjacent described rib-dividing plates 16 is provided with a caressing plate 17, and the bottom end of the caressing plate 17 is higher than the rib-dividing plate 16 bottom. Smoothing the top of the ridge formed by the smoothing plate 17 is convenient for making ponds and farming in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com