Single cantilever type gas sensor with curled structure and sensor array

A gas sensor, single cantilever technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of complex process, difficult positioning, low efficiency, etc., and achieve the effect of simple process, easy preparation, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

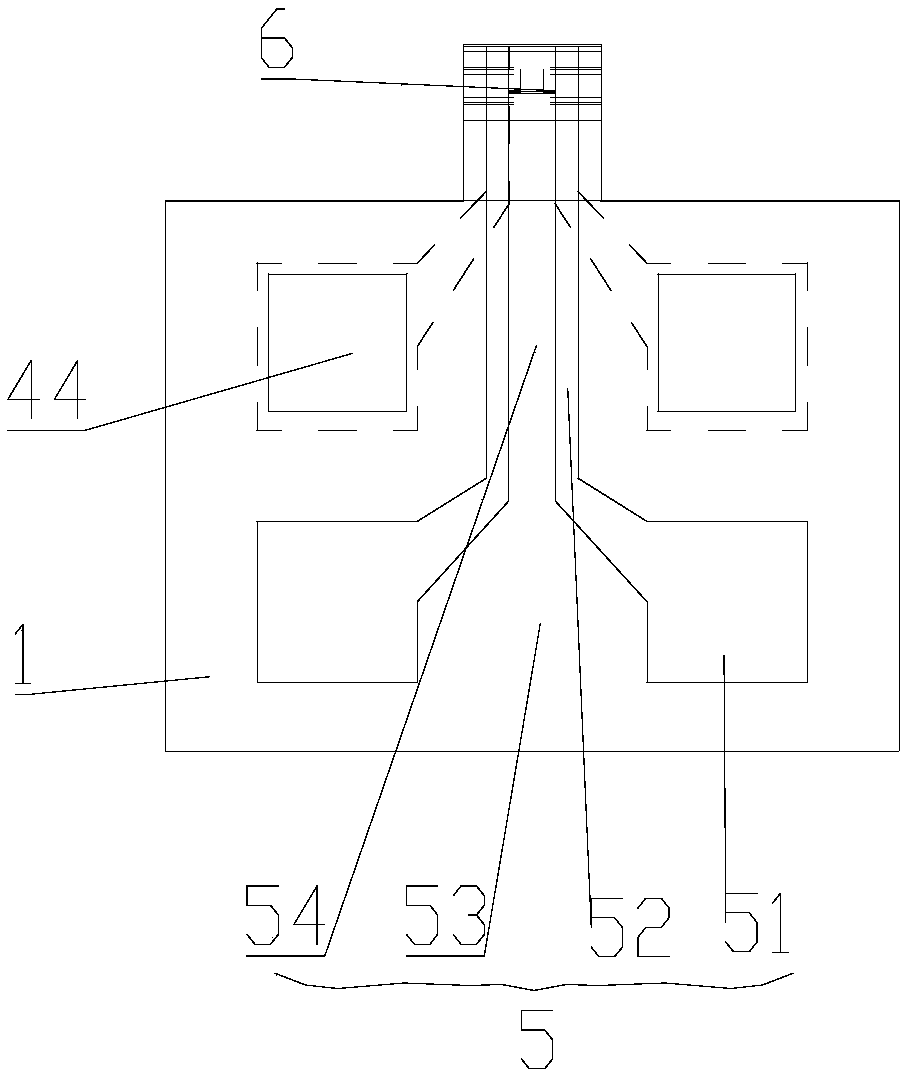

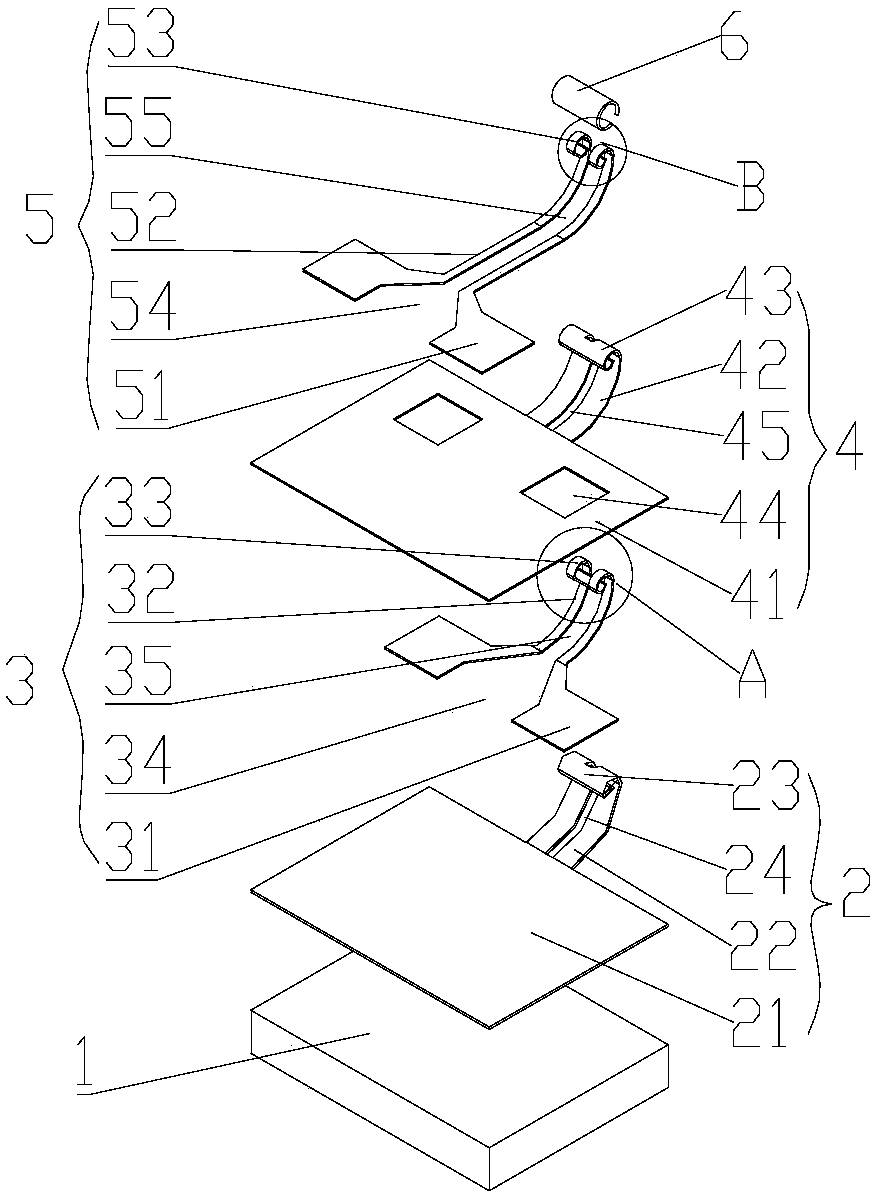

[0034] refer to Figure 1 to Figure 4 , this embodiment provides a warped single-cantilever gas sensor, including a silicon substrate 1 , a support film 2 , a heating resistor 3 , an isolation film 4 , a detection electrode 5 and a gas-sensing material 6 .

[0035] The sensor has a base structure and a suspension beam structure. Generally, the base structure is rectangular, and the suspension beam structure is arranged in the middle of a long side of the base structure. Therefore, the horizontal projection of the sensor is in a "T" shape. Its specific structure is as follows:

[0036] The upper and lower end faces of the silicon substrate 1 are rectangular;

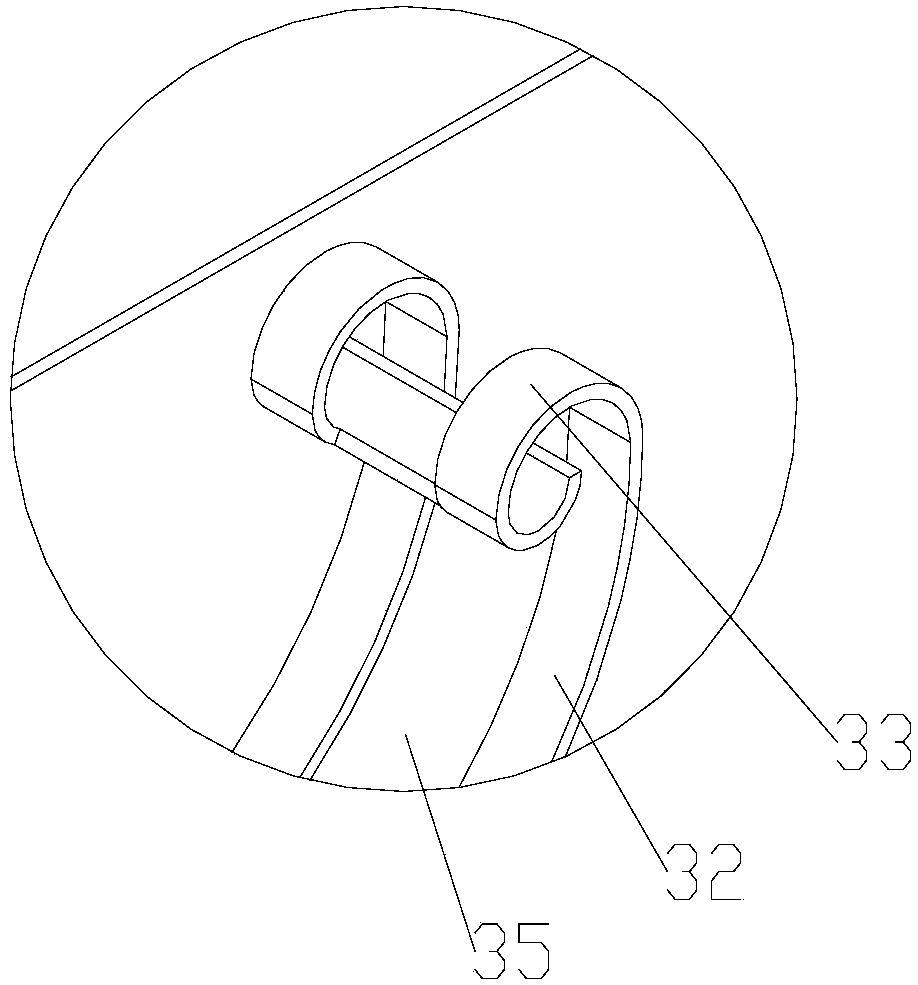

[0037] The support film 2 is used to support the entire suspension beam structure, which is a silicon nitride layer. It includes a first base 21 , a first cantilever 22 and a first crimp 23 . The first base 21 is rectangular, the first cantilever 22 is connected to the middle of a long side of the first base 21, and th...

Embodiment 2

[0060] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the horizontal projections of the first cantilever 22, the second cantilever 32, the third cantilever 42 and the fourth cantilever 52 are all in the shape of an isosceles trapezoid, and the direction, the widths of the first cantilever 22 , the second cantilever 32 , the third cantilever 42 and the fourth cantilever 52 gradually increase. By widening the connection width between the cantilever beam structure and the base structure, while retaining the low power consumption characteristic of the single cantilever beam structure, the mechanical strength of the entire sensor is also improved.

[0061] Compared with the first embodiment, the preparation method of the sensor described in this embodiment is only different in the preparation parameters.

Embodiment 3

[0063] In the application of odor identification, it is often necessary to integrate many sensors to work together. Because of the unique structure of the single cantilever sensor with the coiled structure described in the above-mentioned embodiment 1 and embodiment 2, it is very easy to realize multiple The integration of sensors constitutes a sensor array. Such as Figure 6 As shown, the present embodiment provides a sensor array, which is flattened by the above-mentioned single cantilever sensor with a curled structure, wherein the cantilever structure of each sensor is located on the same side of the base structure. Of course, the cantilever structures of the sensors can also be distributed on both sides of the base structure or in other arrangements as required.

[0064] The preparation method of the sensor array described in this embodiment is equivalent to the preparation method of the sensor in the first embodiment, it only needs to set the etching conditions in step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com