Electrostatic powder spraying machine with automatic spraying function

An electrostatic powder and automatic spraying technology, which is applied in the direction of liquid spraying equipment, spraying devices, liquid supply devices, etc., can solve the problems of poor spraying effect and uneven spraying, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

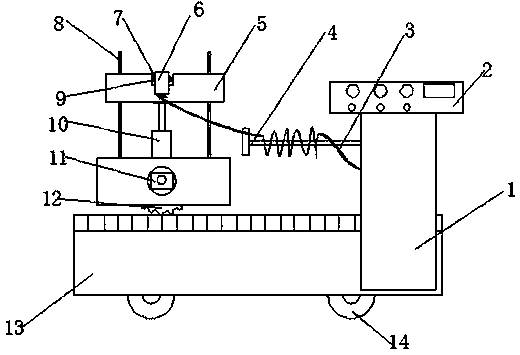

[0016] Such as Figure 1 to Figure 2 The electrostatic powder spraying machine for automatic spraying includes a base 13 , a moving base, a spray gun fixing base 5 , a spraying machine body 1 , a spraying machine console 2 and a spraying gun 6 . The sprayer body 1 is set on the base 13, the moving seat is set on the base 13, and can move left and right on the base 13, set on the base A rack is provided, and a motor and a gear are arranged on the moving seat, and the gear is meshed with the rack. The spray gun fixed seat 5 is arranged on the described moving seat through the lifting cylinder 10 and the guide rod 8, and the vertical movement of the spray gun fixed seat 5 is realized by lifting the lifting cylinder 10.

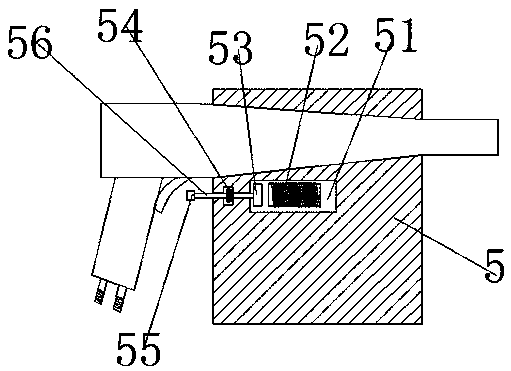

[0017] Spray gun 6 is fixed on the described spray gun holder 5, is provided with slot 7 on described spray gun holder 5, is provided with symmetrical clamping block 9 in described slot 7, described spray gun 6 It is arranged in the slot 7 and clamped by the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com