Crankshaft front oil seal seat and assembly method

An assembly method and oil seal seat technology, which is applied to the sealing device of the engine, machine/engine, manufacturing tools, etc., can solve the interference of peripheral parts and other problems, and achieve the effects of high reliability, simple and convenient operation, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

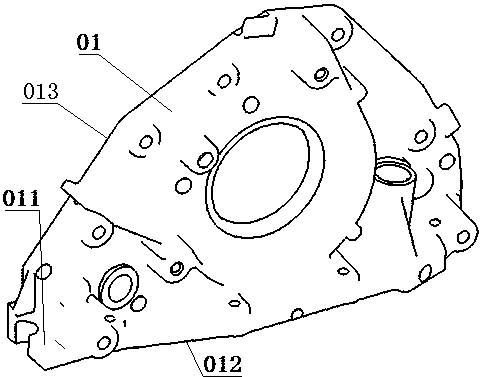

[0016] like figure 1 The shown crankshaft front oil seal seat includes the crankshaft front oil seal seat body 01, a positioning platform 011 is provided on the outer edge of the crankshaft front oil seal seat body 01, and an opening is arranged on the positioning platform 011. The opening is an arc-shaped opening. The axis line of the arc-shaped opening is perpendicular to the positioning surface 012 of the crankshaft front oil seal seat body 01, and the positioning surface 012 of the crankshaft front oil seal seat body 01 is perpendicular to the working surface 013 of the crankshaft front oil seal seat body 01.

Embodiment 2

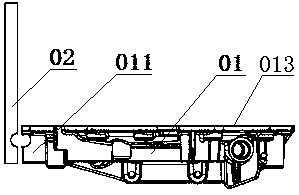

[0018] like figure 1 The shown crankshaft front oil seal seat includes the crankshaft front oil seal seat body 01, a positioning platform 011 is provided on the outer edge of the crankshaft front oil seal seat body 01, and an opening is arranged on the positioning platform 011. The opening is an arc-shaped opening. The axis line of the arc-shaped opening is perpendicular to the positioning surface 012 of the crankshaft front oil seal seat body 01, and the positioning surface 012 of the crankshaft front oil seal seat body 01 is perpendicular to the working surface 013 of the crankshaft front oil seal seat body 01; the crankshaft The assembly method of the front oil seal seat includes the following steps:

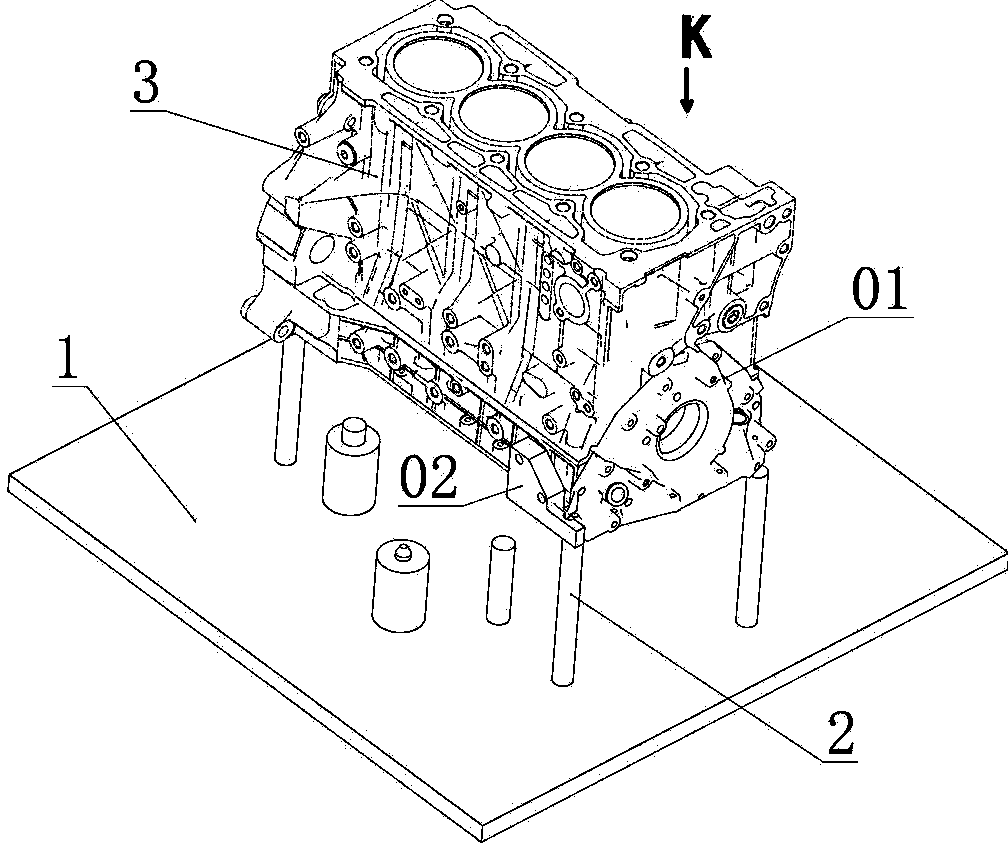

[0019] A. Put the cylinder block 3 on the pallet 1 of the assembly line, install one end of the auxiliary positioning block 02 on one side of the cylinder block 3 through bolts, and the other end of the auxiliary positioning block 02 is provided with the crankshaft front oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com