Multifunction rotavator, speed change gear box thereof capable of reversing easily and extending shaft thereof

The technology of a variable speed gearbox and a rotary tiller is applied in the fields of farming equipment, agricultural machinery and equipment, and application, etc., and can solve the problems of time-consuming and laborious disassembly and assembly, inconvenient adjustment and maintenance, and burying straw into the soil, etc., and achieves simple structure and low cost. Low, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

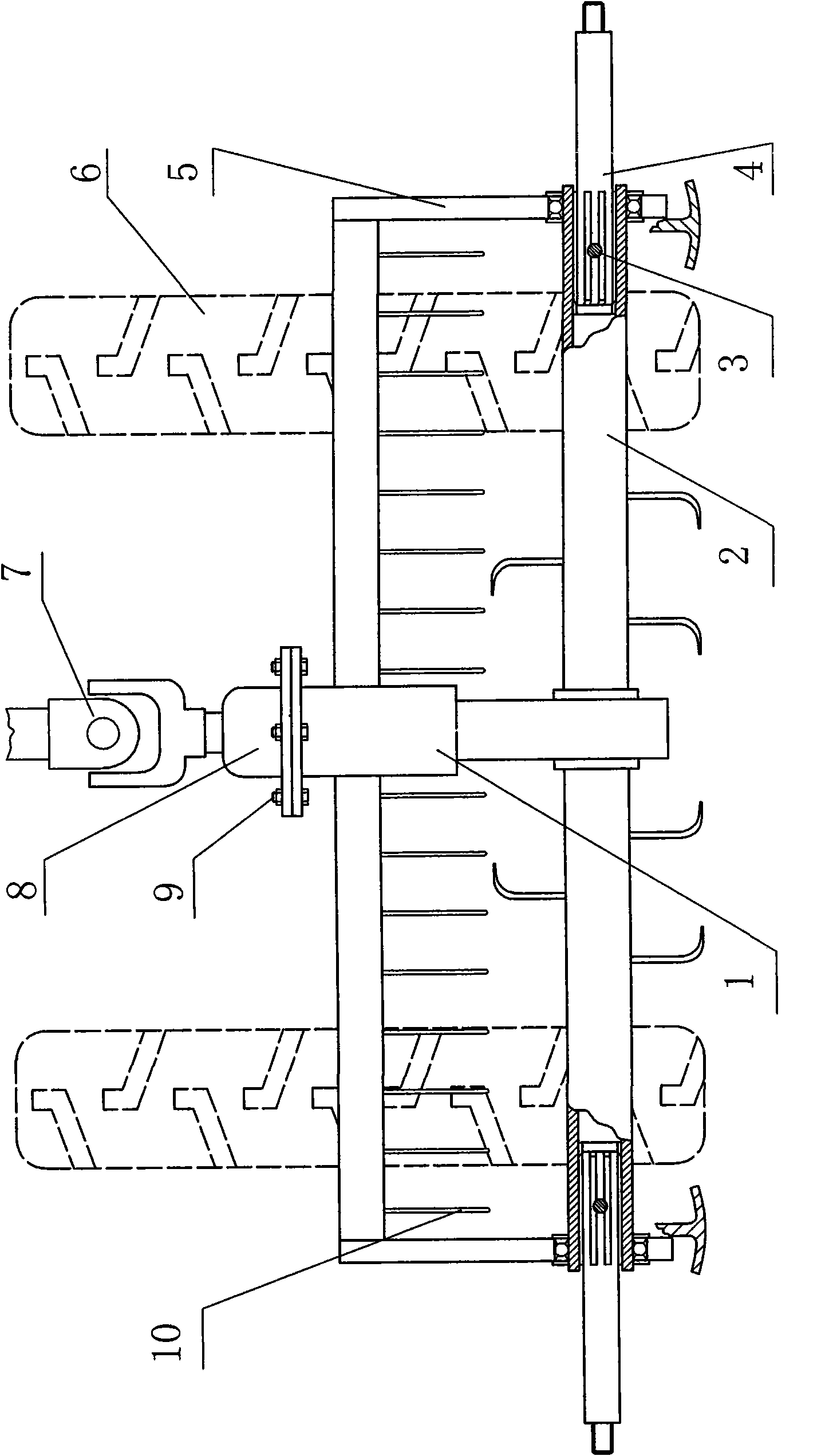

[0041] Embodiment 1, the multifunctional rotary tiller of the present invention, figure 1 It is the structure of Embodiment 1 shown from the rear view direction of the tractor: figure 1 Middle: 1. Gear box lower housing, 2. Coulter shaft, 3. Locking pin, 4. Extension shaft, 5. Rotary cultivator frame, 6. Tractor drive wheel, 7. Universal joint, 8. Gear Case upper shell, 9, connecting bolts, 10, stubble fence. figure 1 The middle coulter shaft 2 is a circular tube structure, the inner walls of both ends are provided with internal splines, the extension shaft 4 is inserted into the coulter shaft 2, and its section is an external spline corresponding to the inner wall of the coulter shaft 2 tube , and use the locking pin 3 to position the two for torque transmission. The cross-sectional shape of the elongated shaft 4 and the tubular coulter shaft 2 can also be polygonal, square or directly cylindrical, and the locking pin 3 is axially positioned to transmit the torque, and the ...

Embodiment 2

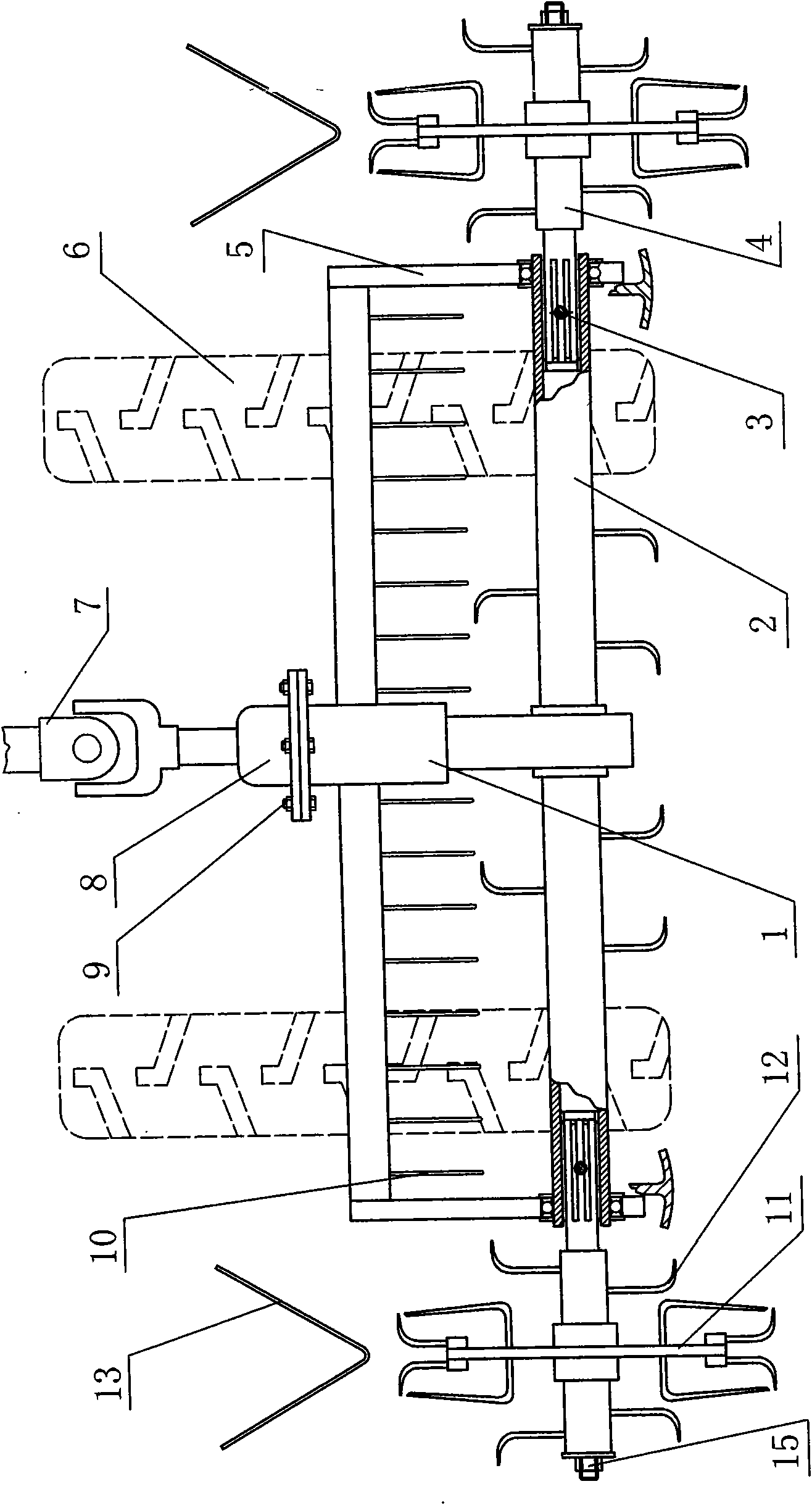

[0043] Embodiment 2, the multifunctional rotary cultivator of assembling ditching cutter head, figure 2 It is the structure of Embodiment 2 of assembling the ditching cutter head on the extension shaft 4 shown from the rear view direction of the tractor, figure 2 Middle: 1. Gear box lower housing, 2. Coulter shaft, 3. Locking pin, 4. Extension shaft, 5. Rotary cultivator frame, 6. Tractor drive wheel, 7. Universal joint, 8. Gear Case upper casing, 9, connecting bolts, 10, stubble fence, 11, ditching cutter head, 12, rotary tiller, 13, soil dividing plate, 15 nuts.

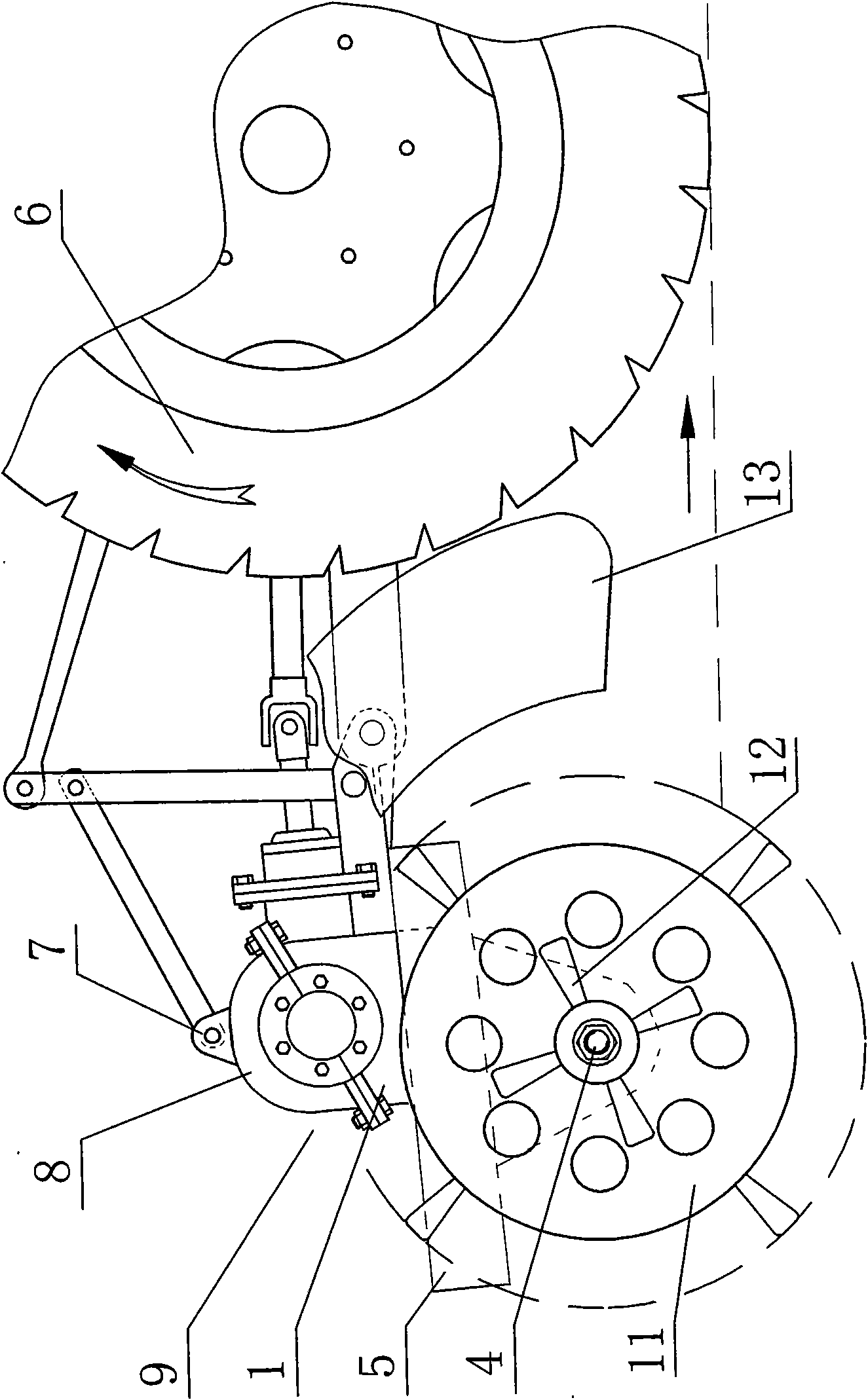

[0044] Figure 3 is with figure 2 Corresponding to the structural diagram shown from the right side of the tractor, in the figure: 1. The lower housing of the gearbox, 4. The extension shaft, 5. The frame of the rotary tiller, 6. The driving wheel of the tractor, 7. The universal joint , 8, the upper casing of the gearbox, 9, the connecting bolts, 11, the ditching cutter head, 12, the rotary tiller. In the fig...

Embodiment 3

[0045] Embodiment 3, a wide-width multifunctional rotary tiller. Figure 4 It is a schematic diagram of assembling a rotary tiller on an extension shaft and expanding it into a wide-width rotary tiller. Figure 4 It is also the rear view direction diagram of the tractor. In the figure: 1. Gear box lower housing, 2. Coulter shaft, 3. Locking pin, 4. Extension shaft, 5. Rotary cultivator frame, 6. Tractor drive wheel, 7. Universal joint, 8. Gear box upper case, 9. Connecting bolts, 10. Stubble fence, 12. Rotary tiller. The coulter shaft tube 14 is a circular tube-shaped structure, which is provided with several rotary cultivators 12, which are set on the extension shaft 4, and have other structures for transmitting torsion such as keys coupled with the extension shaft 4, and nuts on the outside. 15 Tighten.

[0046] If the function of the rotary tiller is to be restored, parts such as the ditching cutter head on the extension shaft and the shaft can be removed, and a dust cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com