A split full paper tray

A split type and tray technology, applied in the field of packaging, can solve the problems of its own structure and fixation, and achieve the effects of small footprint, high packaging efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

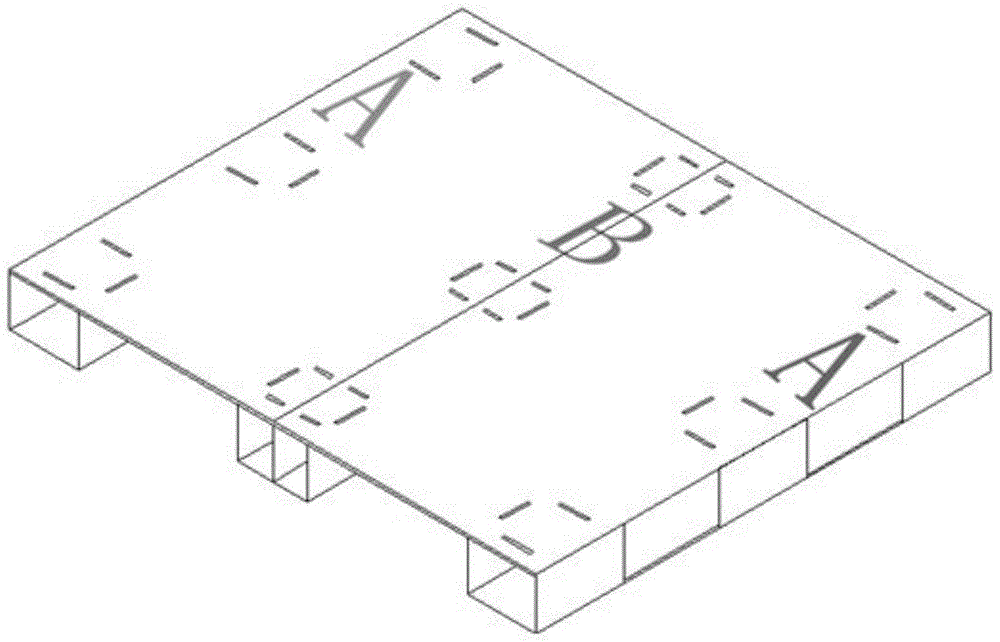

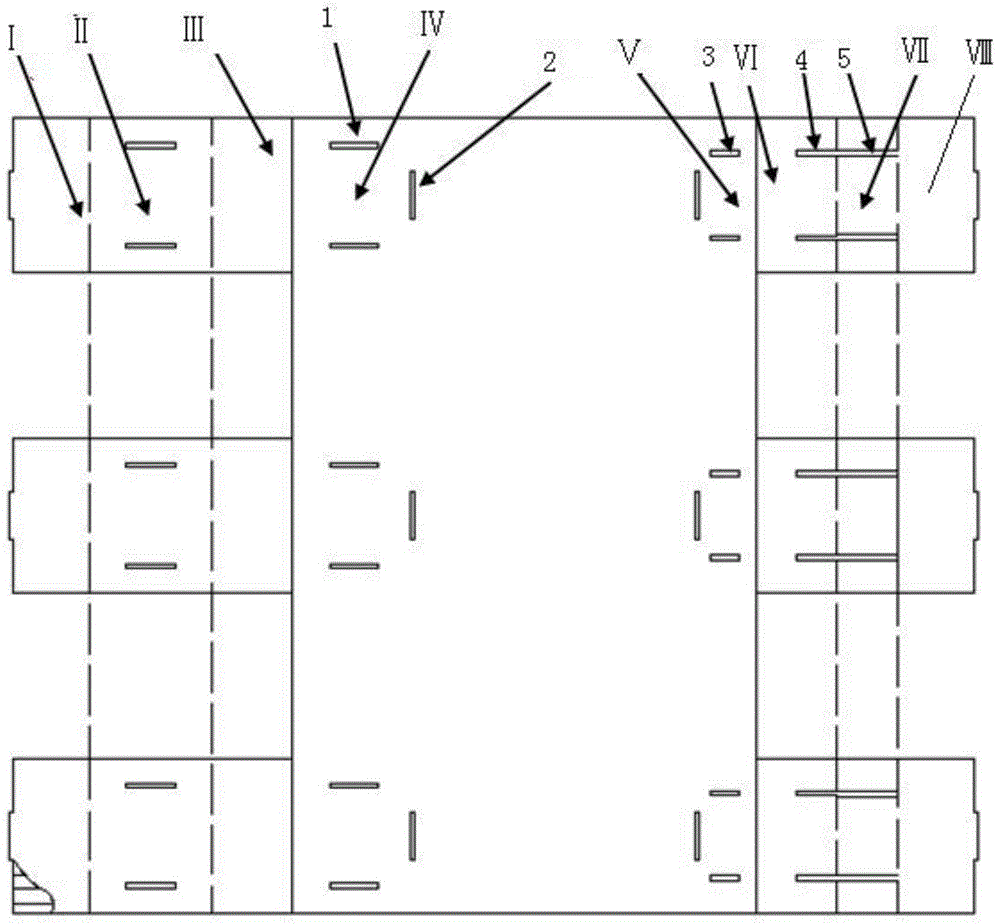

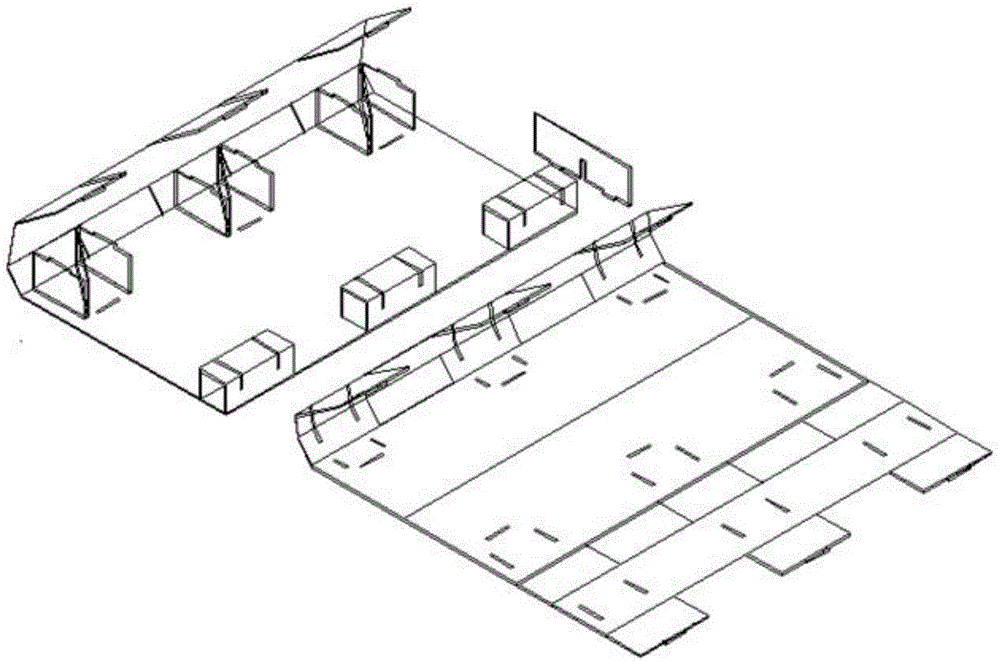

[0037] A split full paper tray, such as figure 1 and image 3 As shown, two main structural parts A are folded and connected by internal support members. The main structural part is composed of a rectangular bearing panel formed by corrugated cardboard, end legs and splicing legs. The main structural part is composed of a corrugated cardboard-paper shaped rectangular bearing panel and two feet at the left and right ends, and the overall tray is composed of two main structural parts. The rectangular load-bearing panel is used for placing items, and the rectangular parallelepiped feet are used for bearing weight. figure 1 There are three end legs shown at A, each of identical construction, each along figure 2 Fold at the dotted line to form a cuboid with a length of 19cm, a width of 15cm, and a height of 10cm. The cuboid is fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com