Method used for prolonging capacitor life

A capacitor and life-span technology, used in capacitors, capacitor manufacturing, circuits, etc., can solve problems such as electrolyte loss of dielectric

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Further detailed explanation through specific implementation mode below:

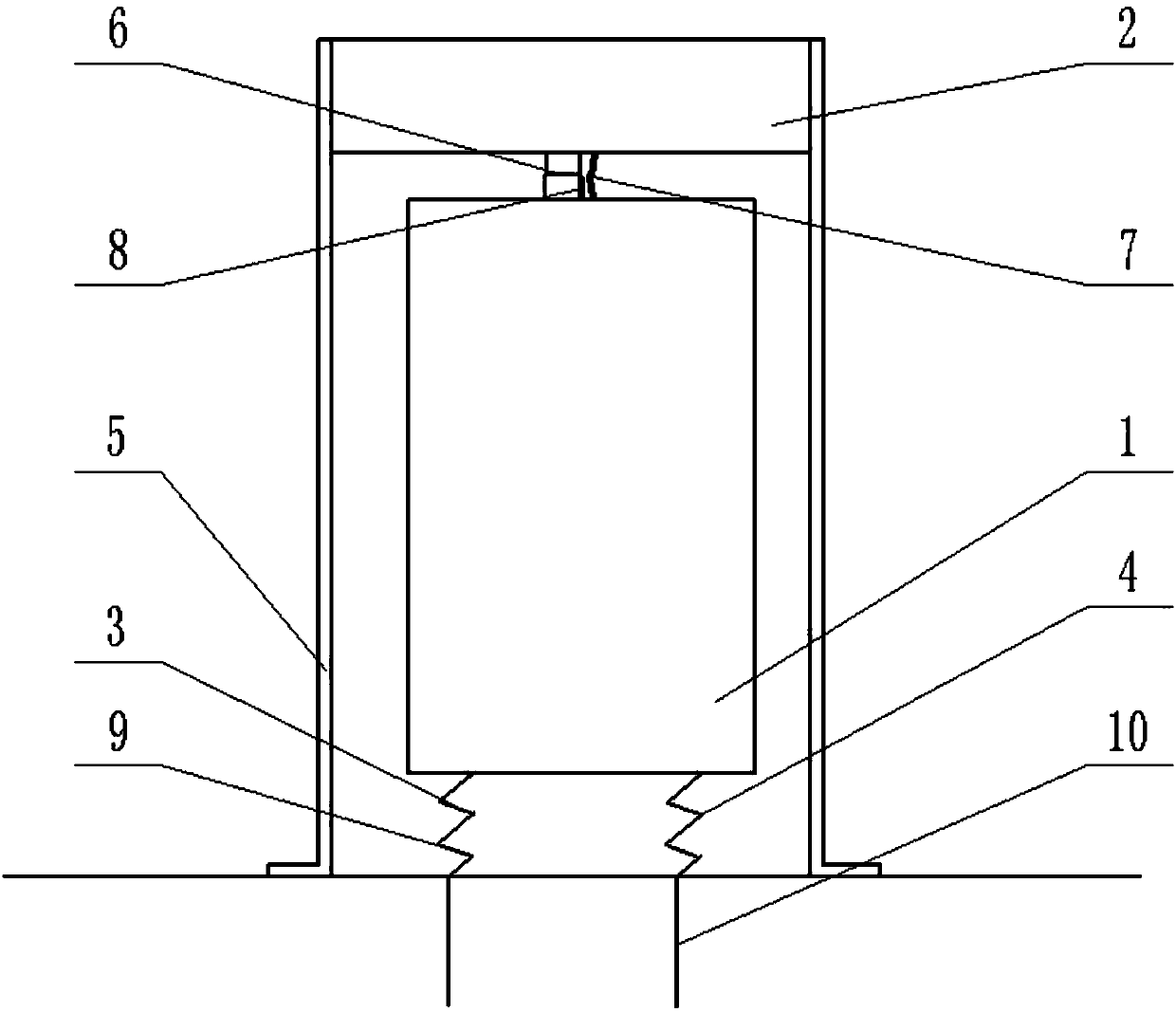

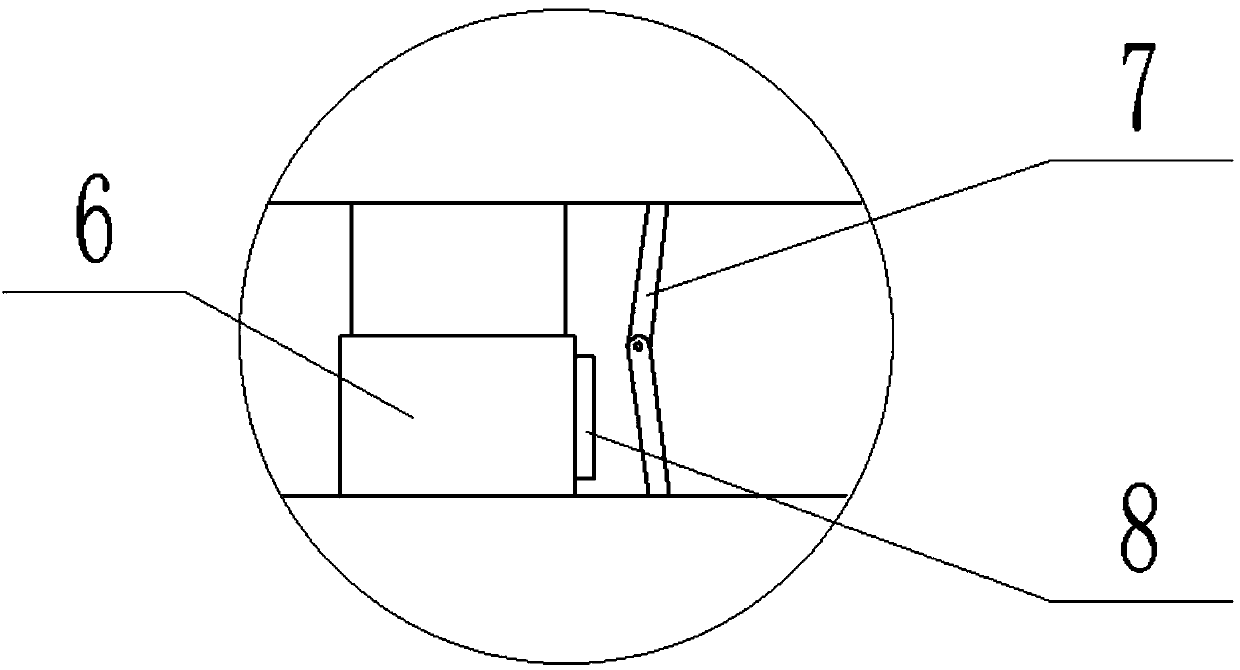

[0027] The reference signs in the accompanying drawings include: box body 1, sub box 2, positive pole 3, negative pole 4, support foot 5, electrolyte tube 6, connecting rod 7, switch button 8, spring part 9, pin part 10.

[0028] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0029] The method for prolonging the service life of capacitor in the present embodiment comprises the following steps:

[0030] S1: After the capacitor in this solution is used for a period of time, the box body 1 becomes lighter and is lifted up by the spring-shaped positive pole 3 and negative pole 4;

[0031] S2: The box body 1 lifted up drives the connecting rod 7 to bend in the direction of the switch button 8 arranged on the electrolyte tube 6;

[0032] S3: The liquid valve is opened after the switch button 8 is pressed by the connecting rod 7;

[0033] S4: The solute in the No. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com