Air bag type grouting hole packer

A hole sealer and grouting hole technology, which is used in sealing/sealing, gas discharge, safety devices, etc., can solve the problems of uneven force on gas drainage pipes, low work efficiency, and poor sealing. The effect of uniform force, cost saving and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

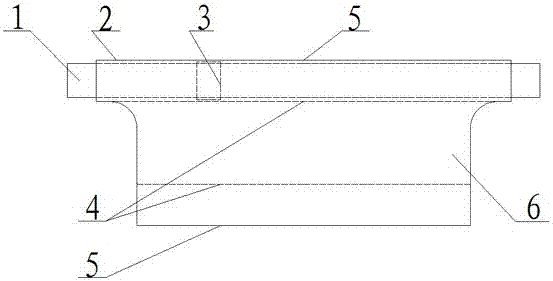

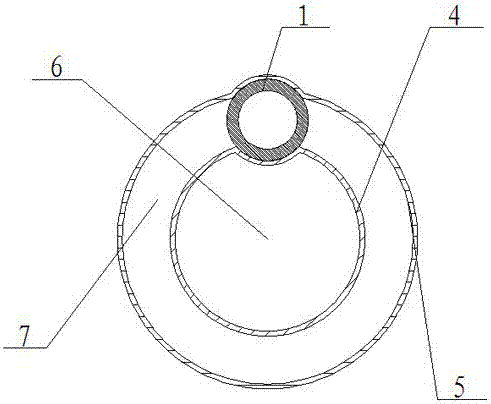

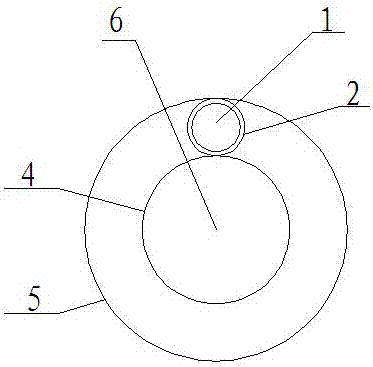

[0015] As shown in the figure, the specific implementation method is as follows:

[0016] A bag-type grouting hole sealing device, including a grouting pipe 1, and a plurality of annular cloth bags arranged at intervals, the annular cloth bag includes an inner wall 4 and an outer wall 5, and the inner wall 4 is wound to form a hole for piercing. Set the through hole 6 of the gas drainage pipe. When it is necessary to install the gas drainage pipe, put the gas drainage pipe in the through hole, and then seal the hole by grouting. When the gas drainage pipe does not need to be installed, directly Grouting can be used to seal the hole. The outer wall 5 is wound around and set on the outside of the inner wall 4. The outer wall 5 and the inner wall 4 are sealed. The outer wall 5 and the inner wall 4 on the two ends of the length direction of the cloth bag respectively extend a section to form a grouting hole 2 connected with the grouting sealing cavity 7, and the grouting pipe 1 ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com