LED panel display structure

A display and panel technology, applied in the direction of static indicators, instruments, electric solid devices, etc., can solve the problems of inability to install driver ICs, inability to achieve small-area high-resolution, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

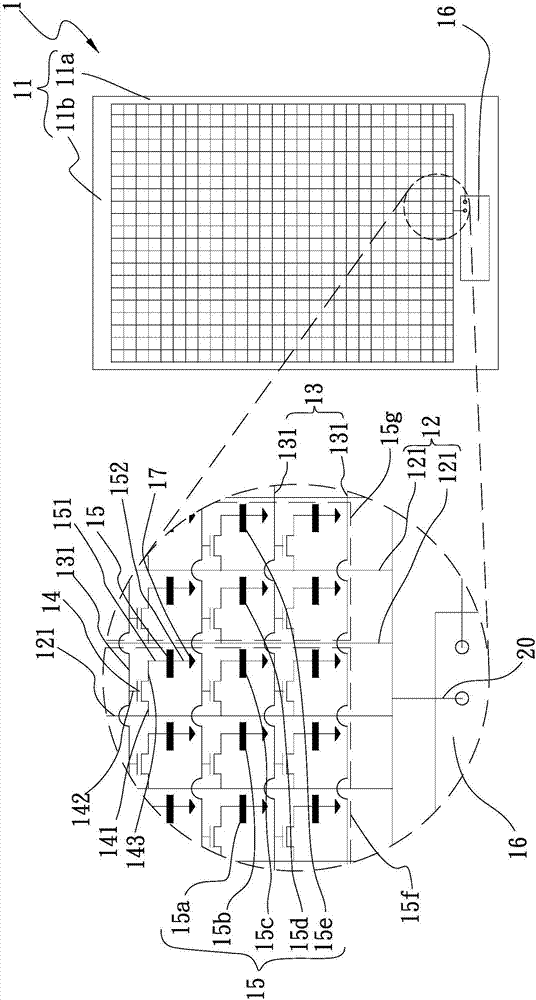

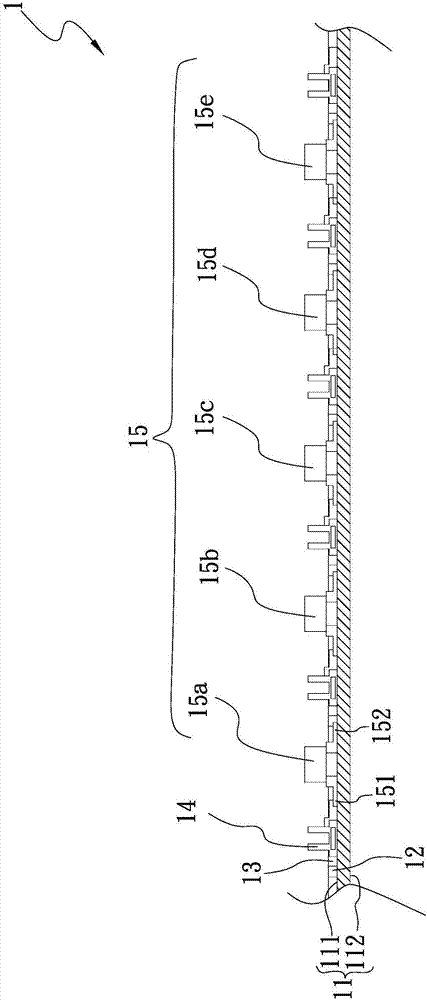

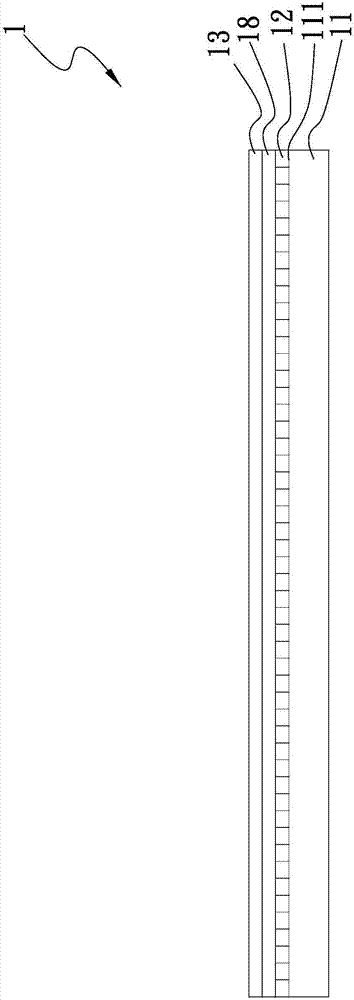

[0017] The above-mentioned purpose of the present invention and its structural and functional characteristics will be described according to the preferred embodiments of the accompanying drawings.

[0018] Such as figure 1 , figure 2 As shown, they are respectively the top view and combined cross-sectional view of the first embodiment of the LED panel display structure provided by the present invention. As shown in the figure, the LED panel display structure 1 provided by the present invention includes: a base 11, a first electrode layer 12. A second electrode layer 13, a plurality of switching elements 14, a plurality of light emitting diode elements 15 and a control chip 16;

[0019] The base 11 has a first side 111 and a second side 112 , and the base 11 is any one of glass, film or flexible substrate.

[0020] The first electrode layer 12 has a plurality of first electrode lines 121, and the plurality of first electrode lines 121 are longitudinally extended and arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com