Wire drawing device for detecting tensile performance of electric heating wire

A heating wire and tensile strength technology, applied in the field of wire drawing devices for testing the tensile properties of heating wires, can solve the problems of inconvenient heating wire pulling, inconvenient fixing of the heating wire, inconvenient operation of breaking the heating wire, etc. The effect of pulling performance and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0016] The technical scheme of concrete implementation of the present invention is:

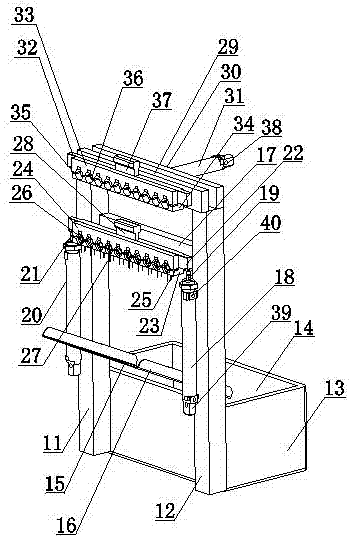

[0017] Such as figure 1 As shown, a wire drawing device for testing the tensile performance of an electric heating wire includes a first support pipe 11 and a second support pipe 12, and a recovery frame 13 is arranged between the lower ends of the first support pipe 11 and the second support pipe 12, and the recovery The inside of the frame 13 is provided with a recovery tank 14, and the top of the recovery frame 13 is an open structure; a horizontal bar 17 is provided between the upper ends of the first support pipeline 11 and the second support pipeline 12; the side po...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap