Heat pump heat supply type drying device

A drying device and heat pump technology, applied in the direction of drying gas arrangement, non-progressive dryer, dryer combination, etc., can solve the problem of lack of vertical lifting adjustment mechanism of hot air dryer, low efficiency of thermal drying treatment of plates, etc. Inconvenient positioning and installation of boards, etc., to achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

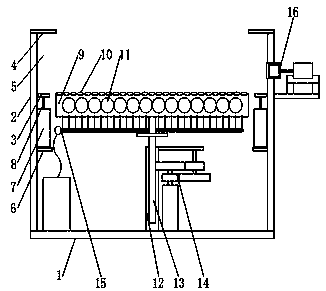

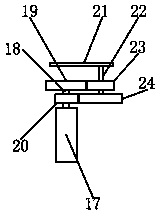

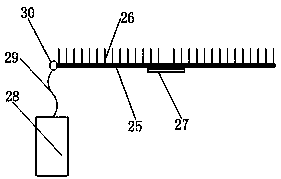

[0021] Such as Figure 1 to Figure 4 As shown, the heat pump heating drying device includes a base 1, side seats 2 are provided on both sides of the base 1, a lifting and clamping seat 3 is provided on the inward facing surface of the side seat 2, and a lifting and clamping seat 3 is provided on the top of the side seat 2. The top seat 4, between the top seat 4 and the lifting clamping seat 3 is a clamping chamber 5; the inward facing position of the side seat 2 is provided with a hydraulic cylinder 7, the upper part of the hydraulic cylinder 7 is provided with a piston rod 8, and the piston rod 8 The end of the bottom of the lifting clamping sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com