Inert chemical product charging bucket cleaning device

A technology for chemical products and cleaning devices, which is applied in the fields of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve the problems of poor cleaning effect, long time consumption, and serious operator injury.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

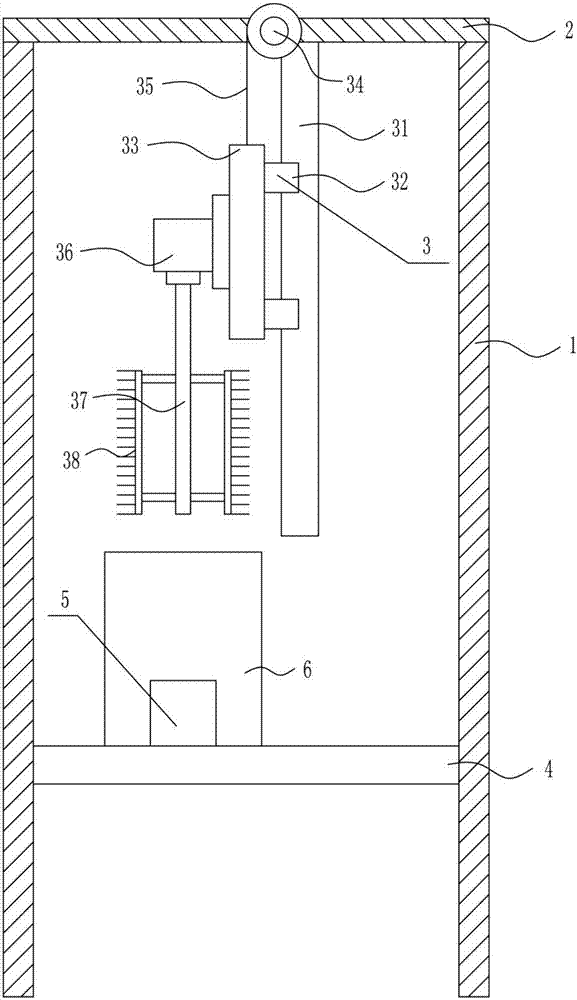

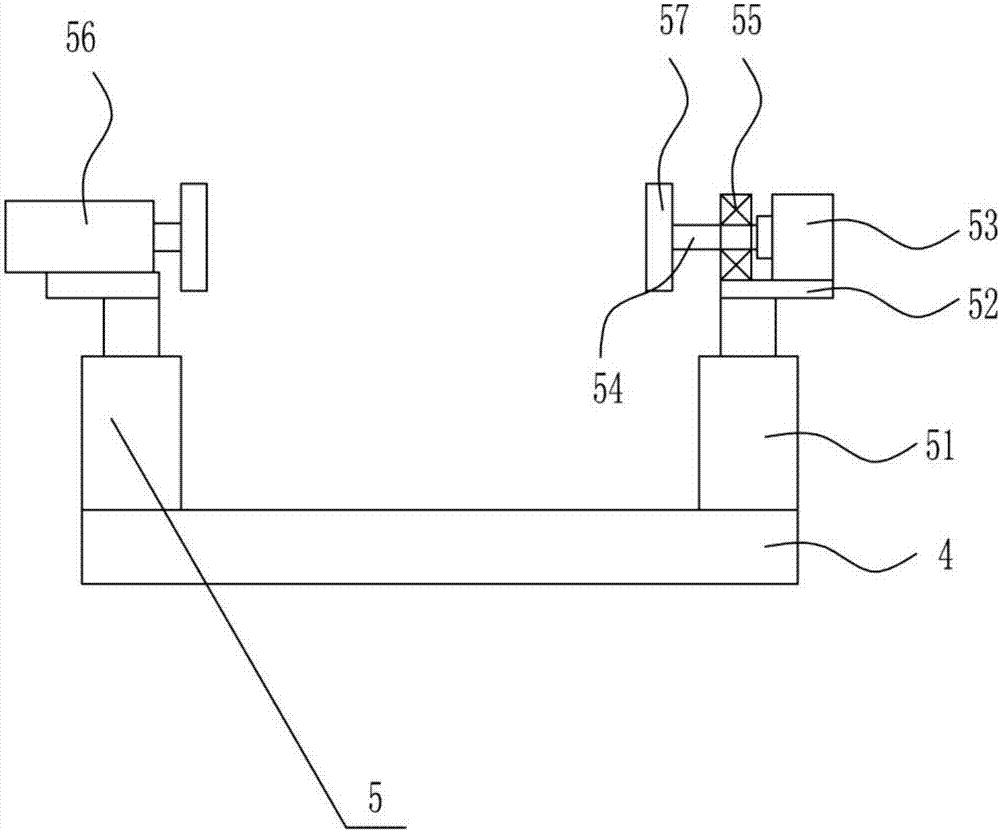

[0030] An inert chemical product charging tank cleaning device, such as Figure 1-4 As shown, it includes a support leg 1, a first support plate 2, a cleaning mechanism 3, a second support plate 4, and a turning and dumping mechanism 5. The tops of the left and right support legs 1 are horizontally placed with a first support plate 2, and the first support plate 2 A cleaning mechanism 3 is installed in the middle of the bottom, and a second support plate 4 is connected to the upper position of the bottom between the left and right side legs 1, and a turning and dumping mechanism 5 is installed on the second support plate 4.

Embodiment 2

[0032] An inert chemical product charging tank cleaning device, such as Figure 1-4 As shown, it includes a support leg 1, a first support plate 2, a cleaning mechanism 3, a second support plate 4, and a turning and dumping mechanism 5. The tops of the left and right support legs 1 are horizontally placed with a first support plate 2, and the first support plate 2 A cleaning mechanism 3 is installed in the middle of the bottom, and a second support plate 4 is connected to the upper position of the bottom between the left and right side legs 1, and a turning and dumping mechanism 5 is installed on the second support plate 4.

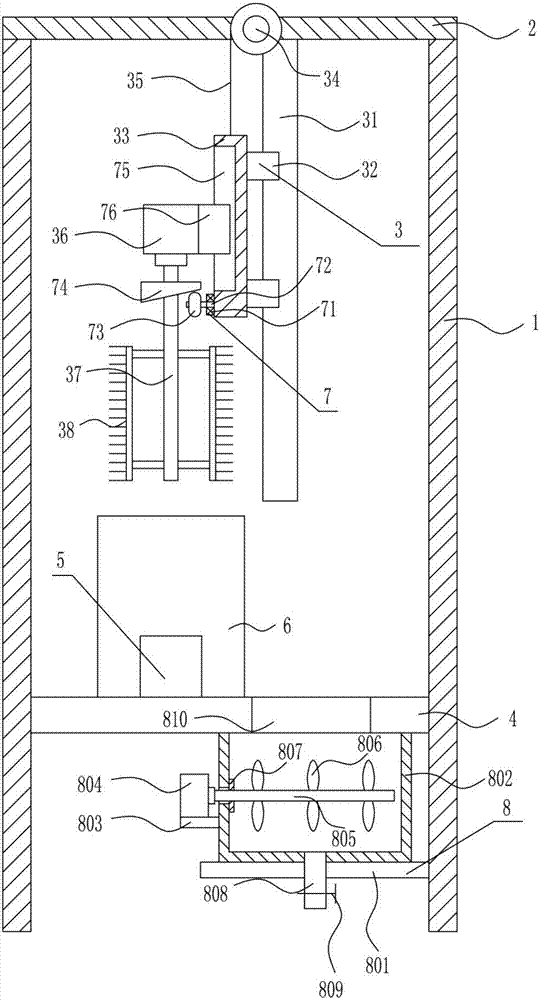

[0033] The cleaning mechanism 3 includes a first slide rail 31, a first slide block 32, a fixed plate 33, an electric reel 34, a stay wire 35, a first motor 36, a first rotating rod 37 and a first brush plate 38, the first The middle of the bottom of the support plate 2 is vertically connected with a first slide rail 31, the first slide rail 31 is slidabl...

Embodiment 3

[0035] An inert chemical product charging tank cleaning device, such as Figure 1-4 As shown, it includes a support leg 1, a first support plate 2, a cleaning mechanism 3, a second support plate 4, and a turning and dumping mechanism 5. The tops of the left and right support legs 1 are horizontally placed with a first support plate 2, and the first support plate 2 A cleaning mechanism 3 is installed in the middle of the bottom, and a second support plate 4 is connected to the upper position of the bottom between the left and right side legs 1, and a turning and dumping mechanism 5 is installed on the second support plate 4.

[0036] The cleaning mechanism 3 includes a first slide rail 31, a first slide block 32, a fixed plate 33, an electric reel 34, a stay wire 35, a first motor 36, a first rotating rod 37 and a first brush plate 38, the first The middle of the bottom of the support plate 2 is vertically connected with a first slide rail 31, the first slide rail 31 is slidabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com