Solid contact conducting layer based on magnetic field induction, and solid ion specific electrode

An ion-selective, conductive layer technology, applied in the direction of material analysis, measuring devices, instruments, etc. through electromagnetic means, can solve the problems of complex devices, cumbersome and time-consuming operations, etc., and achieve the effects of easy control, simple operation, and rapid preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

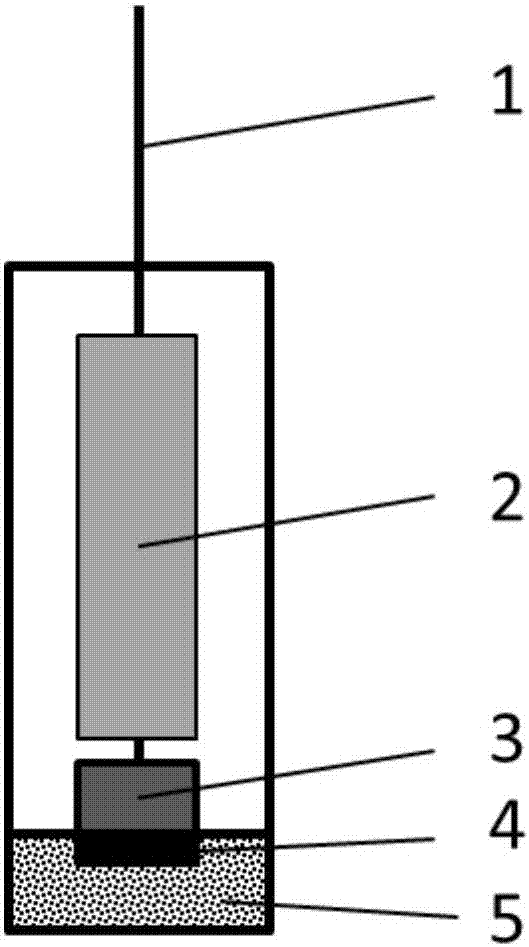

[0032] The invention provides a preparation method of the ion selective electrode, comprising the steps of:

[0033] (1) Using magnetic field-induced self-assembly technology to adsorb magnetic graphene on the electrode surface to prepare a magnetic graphene-modified electrode substrate;

[0034] (2) The surface of the electrode substrate prepared in step (1) is pasted with a polymer sensitive membrane containing an ionophore by tetrahydrofuran, and dried at room temperature to form the ion-selective electrode.

Embodiment 1

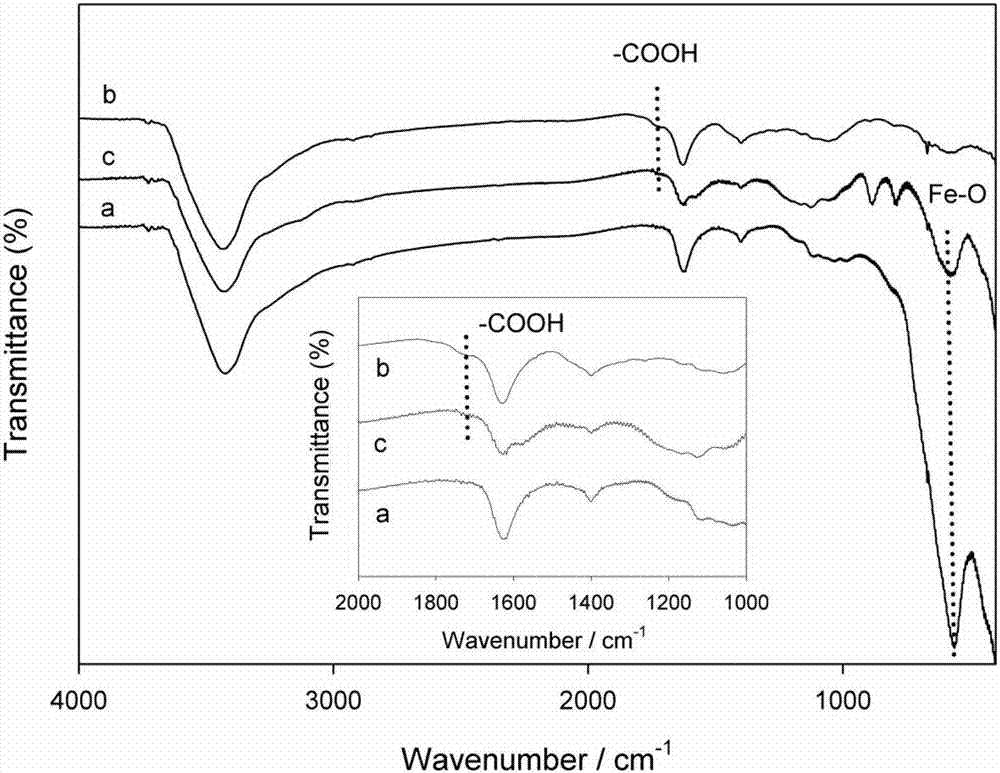

[0035] The comparison of the infrared spectrogram of embodiment 1 magnetic graphene, ferric oxide and graphene oxide

[0036] Comparison of infrared spectra of magnetic graphene, ferroferric oxide and graphene oxide, including:

[0037] (1) get about 1mg magnetic graphene, ferroferric oxide and graphene oxide respectively, then add respectively in 100mg potassium bromide powder, compress tablet, put into the mensuration of infrared spectrum in Fourier transform infrared spectrometer; Magnetic graphene is composed of reduced graphene modified by ferric oxide. The preparation method is to weigh 0.225g graphene oxide and disperse it in 62.5ml deionized water. After ultrasonication for 1h, it is mixed with 1.6M FeCl3 and 0.8M The solution of FeSO4 is mechanically stirred and mixed, and the pH of the reaction solution is adjusted by slowly adding ammonia solution = 10, so that the ferric oxide particles are deposited on the graphene oxide sheet, then the reaction solution is heated...

Embodiment 2

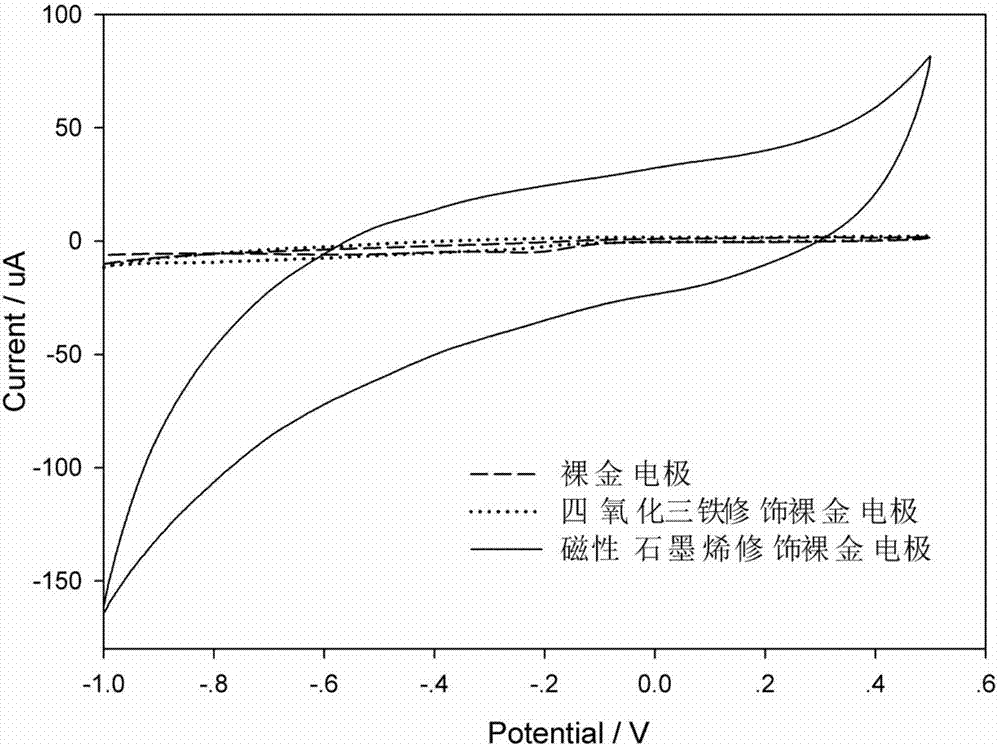

[0040] The comparison of the cyclic voltammogram of embodiment 2 magnetic graphene and ferroferric oxide modified electrode matrix and bare gold electrode

[0041] Comparison of cyclic voltammograms of magnetic graphene and Fe3O4-modified electrode substrates with bare gold electrodes, including:

[0042](1) Weigh each 3mg of magnetic graphene and ferroferric oxide solid powder with a balance, and then use magnetic field induction to adsorb on the magnetic gold plate electrode respectively, that is, the electrode substrate and ferric ferric oxide modified by magnetic graphene are obtained. Modified electrode substrate;

[0043] (2) The magnetic graphene-modified electrode substrate obtained in step (1), the ferroferric oxide-modified electrode substrate and the bare gold electrode were respectively used as working electrodes, Ag / AgCl (3M KCl) was used as a reference electrode, and platinum wire was used as an auxiliary electrode. Electrode, connect the three-electrode system ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap