Built-in wire sorting box device with optical fiber tank

A cable management box, fiber box technology, applied in the direction of light guide, optics, optical components, etc., can solve the problem of the box door cannot be closed, and achieve the effect of being conducive to stability, improving reliability, and convenient installation and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

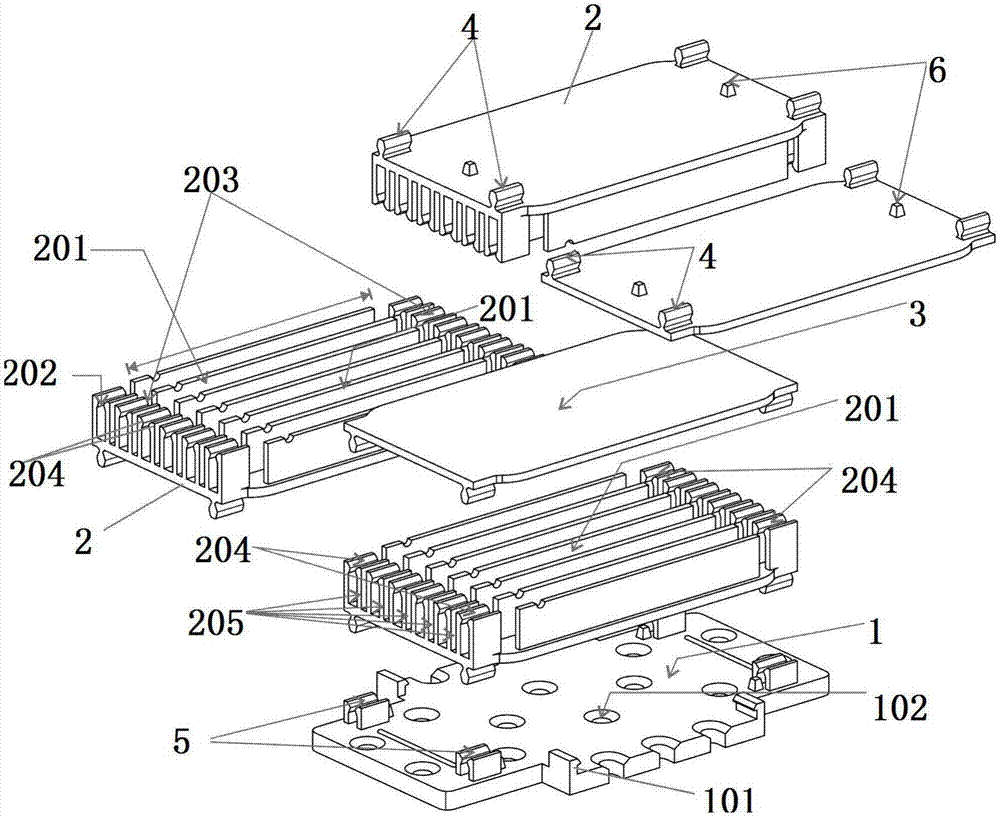

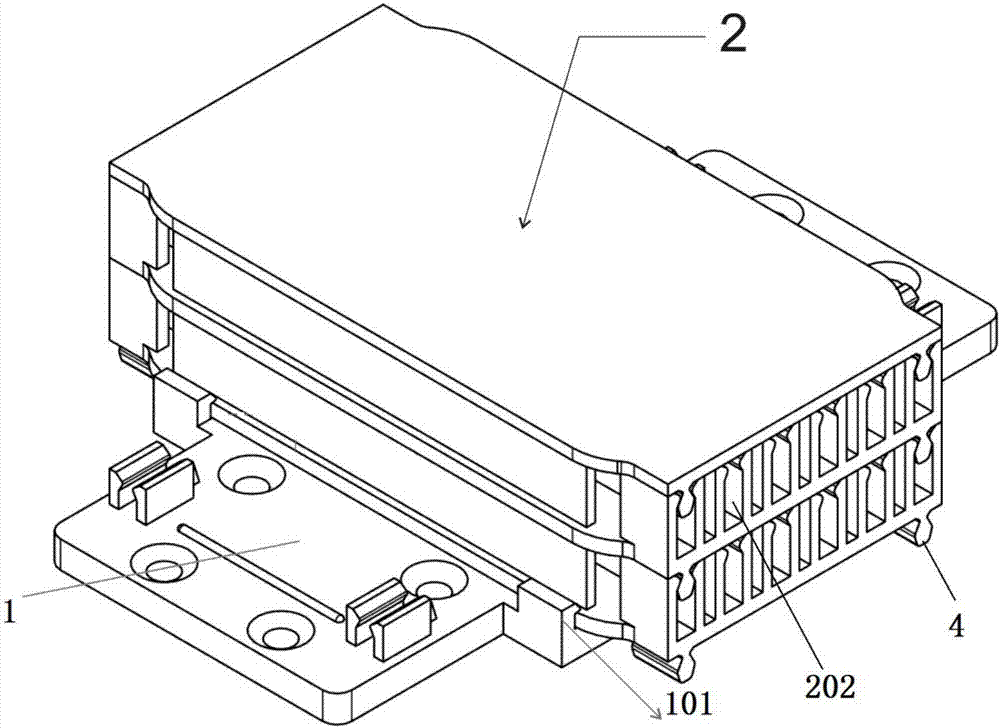

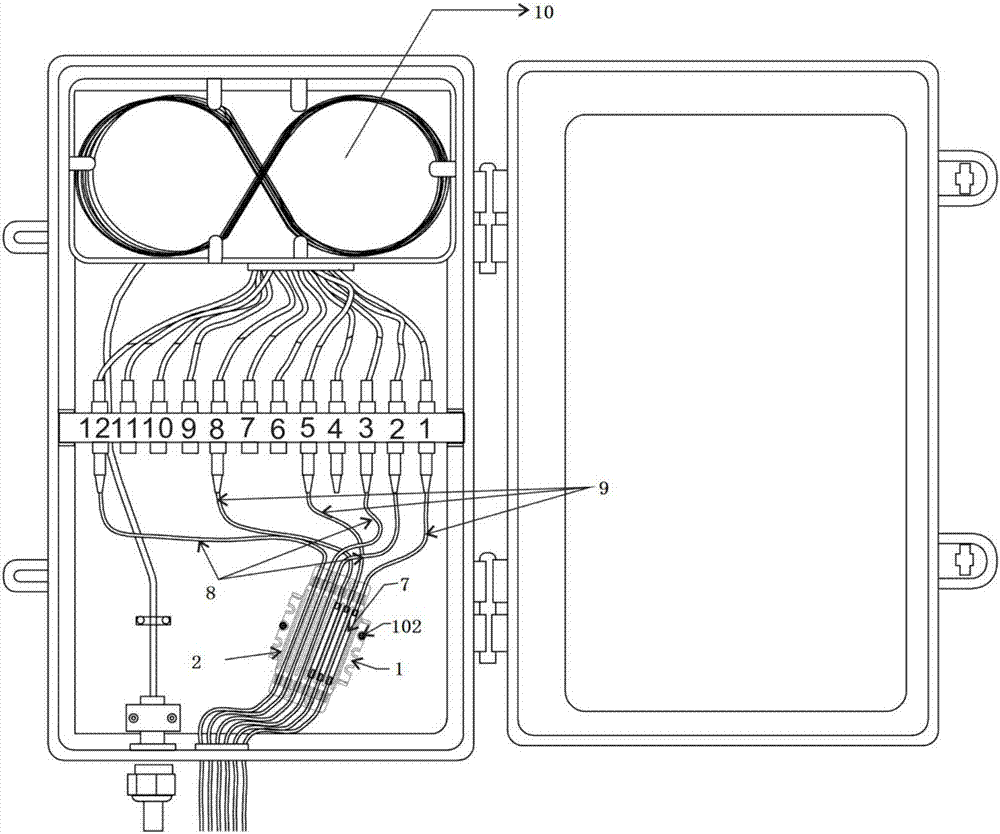

[0025] Such as figure 1 As shown, this embodiment discloses a built-in cable management box device in a fiber optic box, which includes a base 1, a cover plate 3 matched with the above base, and a wiring body 2 arranged between the above base 1 and the cover plate 3 .

[0026] One end surface of the above-mentioned wiring body 2 is provided with a plurality of wiring grooves 201, and the two ends of the above-mentioned wiring groove 201 are provided with a number of clamping grooves 202, and the other end surface of the above-mentioned wiring body 2 is provided with a protruding connection 4, the above-mentioned connecting piece 4 is matched with the top of the above-mentioned wire holding groove 201, or the above-mentioned connecting piece 4 is matched with the connecting groove 5 provided on the above-mentioned base 1.

[0027] In this embodiment, the above-mentioned cover plate 3 is provided with the above-mentioned protruding connecting piece 4, and the above-mentioned co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com