Exhaust purifier

A technology of tail gas purifier and air vent, which is applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve problems such as affecting exhaust, clogging filter elements, accumulation of particle dust, etc., achieves novel structure and avoids tail gas treatment Poor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

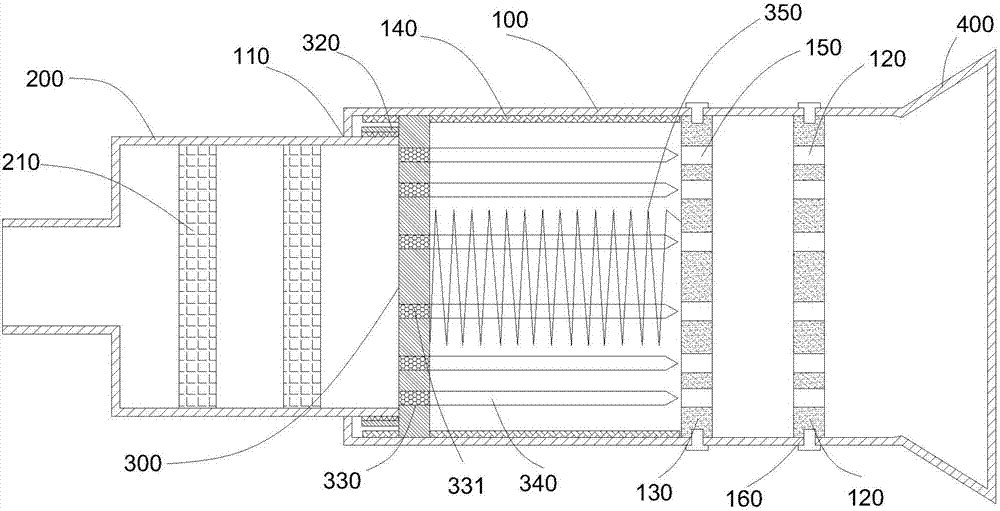

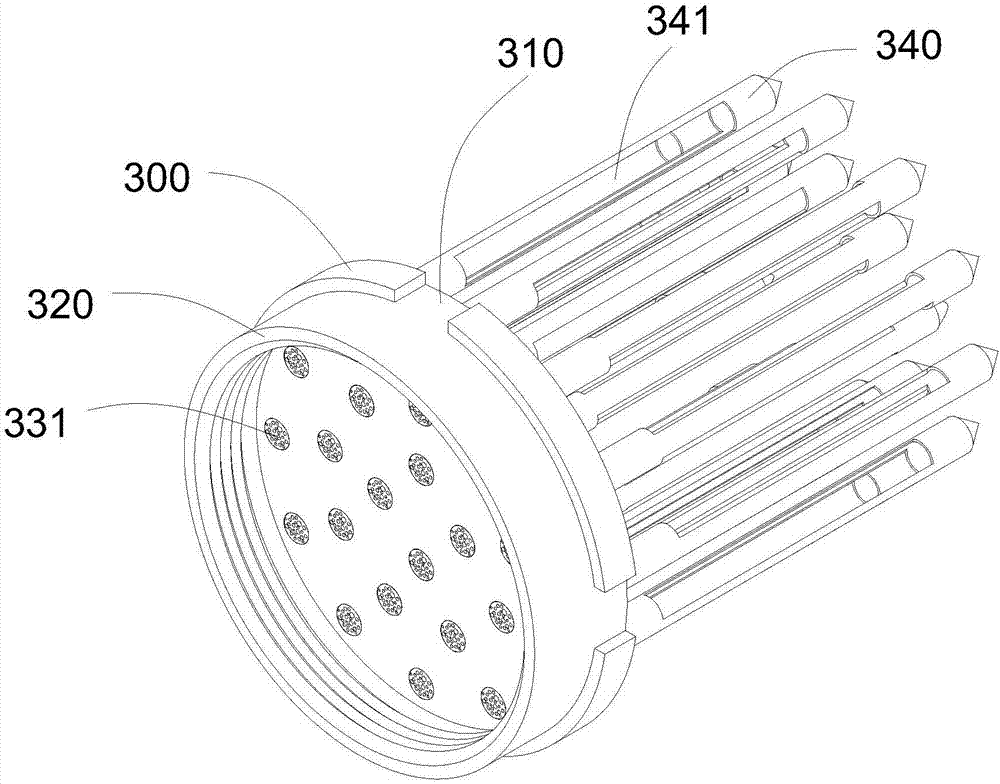

[0021] Such as figure 1 As shown, an exhaust gas purifier is provided in this embodiment, comprising a casing 100 and a push member 200 of tubular structure, one end of the casing 100 is open and the other end is sealed, and the end surface of the sealing end of the casing 100 is A locking hole 110 is provided, the diameter of the locking hole 110 is equal to the outer diameter of the pushing piece 200, and the pushing piece 200 can enter and leave the housing 100 through the locking hole 110; close to the opening The housing 100 at the end is provided with a first filter plate 120 and a second filter plate 130, the outer diameter of the first filter plate 120 and the second filter plate 130 is equal to the inner diameter of the housing 100, and The first filter plate 120 is located on the side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com