System and method for treating white smoke plume of desulfurization flue gas

A white and plume technology, applied in chemical instruments and methods, separation methods, gas treatment, etc., can solve problems such as adverse effects on boiler heat utilization efficiency, increase system energy consumption, and affect boilers, so as to improve technical economy and reliability Tonality, reduce the area of heat exchanger, reduce the effect of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

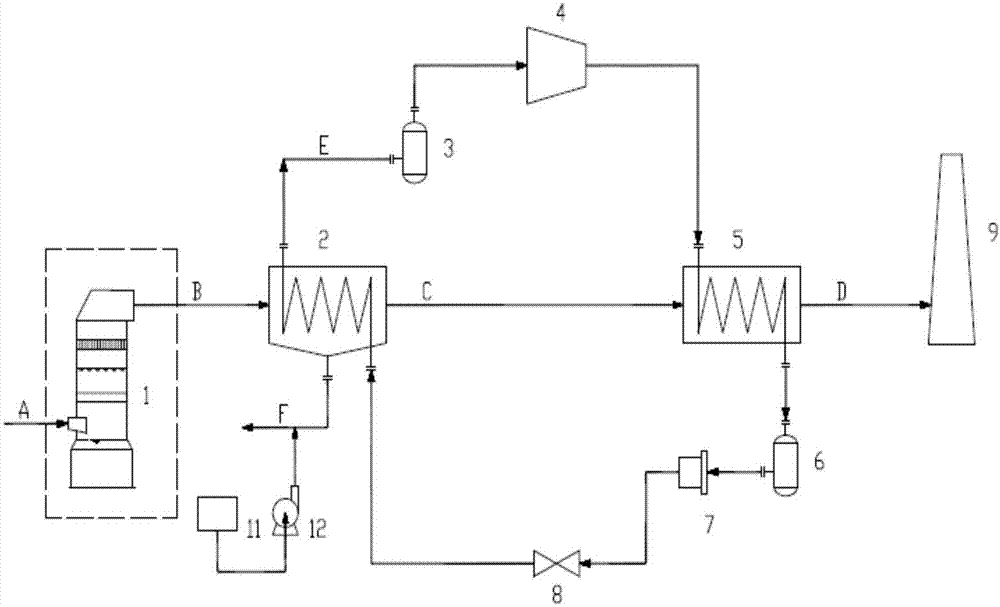

[0038] Attached to the following figure 1 The specific embodiment 1 of the present invention will be described in detail, taking a 300MW coal-fired power generating unit wet desulfurization saturated clean flue gas as an example.

[0039] The local atmospheric pressure in winter is 91.33kPa, the temperature of the high-temperature saturated net flue gas B at the outlet of wet desulfurization equipment 1 is 51.4 °C, and the water vapor content is 14.27%, and enters the evaporator 2; after cooling, the temperature of the low-temperature saturated net flue gas C is 50.0 °C, and the water The steam content is 13.32%, leaving the evaporator 2 and entering the condensing reheater 5; the low-temperature saturated clean flue gas C is heated by the condensing reheater 5 to a temperature of 21.4 °C, and the temperature of the reheated clean flue gas D reaches 71.4 °C, and the water vapor in the flue gas is concentrated. The pressure is only 12.3kPa, which belongs to unsaturated flue gas...

Embodiment 2

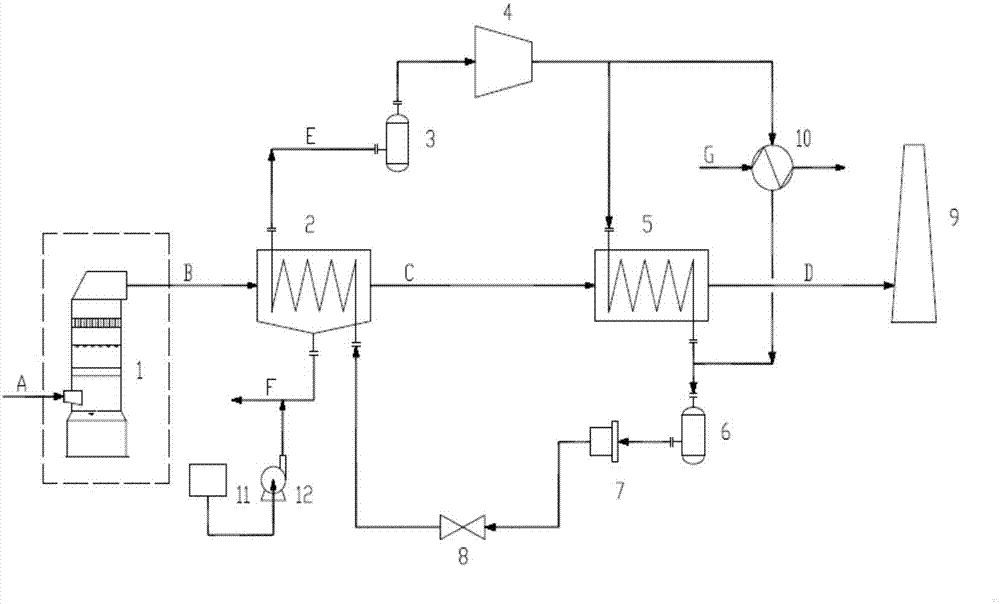

[0046] Attached to the following figure 2 The specific embodiment 2 of the present invention will be described in detail, still taking the aforementioned 300MW coal-fired power generating unit wet desulfurization saturated clean flue gas as an example. The water loss of the wet desulfurization system includes four items: the evaporative water volume of the absorption tower, the waste water discharge, the water volume of the gypsum, and the water volume of the external flue gas, totaling about 62.2t / h. In order to achieve "zero water make-up" in the desulfurization system, it is necessary to cool the high-temperature saturated clean flue gas B to 40.9 °C to recover enough water to be used as the process water make-up water for the desulfurization system.

[0047] The high temperature saturated clean flue gas B at the outlet of wet desulfurization equipment 1 has a temperature of 51.4°C and a water vapor content of 14.27%, and enters the evaporator 2; The evaporator 2 enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com