Feedback type energy-saving stone crusher and ore stone crushing method

A stone crusher and feedback technology, applied in grain processing, etc., can solve the problems of high energy consumption and low efficiency, and achieve the effect of reducing energy consumption and improving the efficiency of crushing stones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

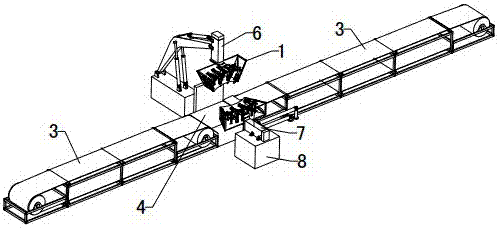

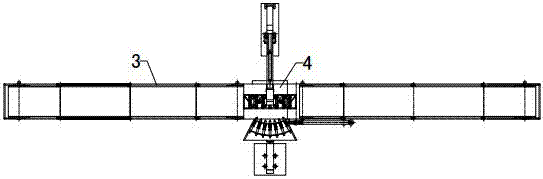

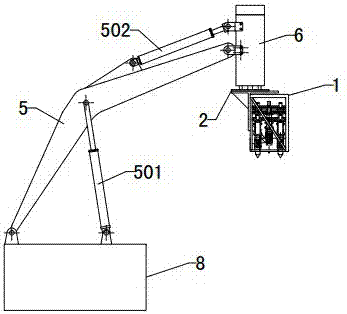

[0033] Refer to attached Figure 1~2 : A feedback type energy-saving stone crusher, comprising a conveyor 3, a crushing stone clamping and impacting device 1 positioned at one side of the conveyor 3, and a detection head 9 installed at the feeding end of the conveyor 3, and the crushing stones clamping and impacting device 1 is set Above the conveyor 3, one side of the gravel clamping and impacting device 1 is respectively provided with a push-out mechanism to drive its overall movement; both the gravel clamping and impacting device 1 and the detection head 9 are provided with a plurality of radially arranged punches , each punch is respectively provided with individually controlled electromagnetic drivers and sensors 104 . The sensors 104 include shock sensors and acoustic wave sensors.

[0034] Conveyor 3 can be a plurality of conveying rollers arranged in parallel, and protective baffles are set on both sides of the conveying rollers to prevent the rolling of stone materia...

Embodiment 2

[0047] Two sets of horizontal gravel clamping and impacting devices 1 are provided, and two sets of horizontal gravel clamping and impacting devices 1 are symmetrically arranged on both sides of the conveyor 3 . Other settings and working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com