Threaded steel sleeve press fitting floating mechanism and press fit method thereof

A floating mechanism and push mechanism technology, applied in the field of machinery, can solve the problems of easy thread slippage, influence of product yield, inability to meet assembly and repeated disassembly, etc., to achieve the effect of fast and accurate press-fitting and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

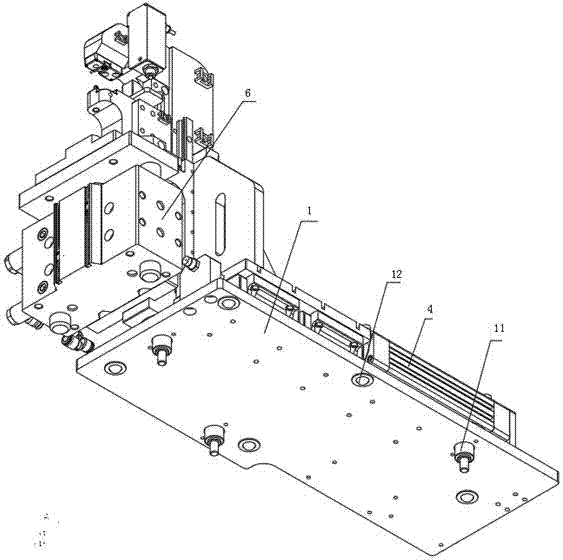

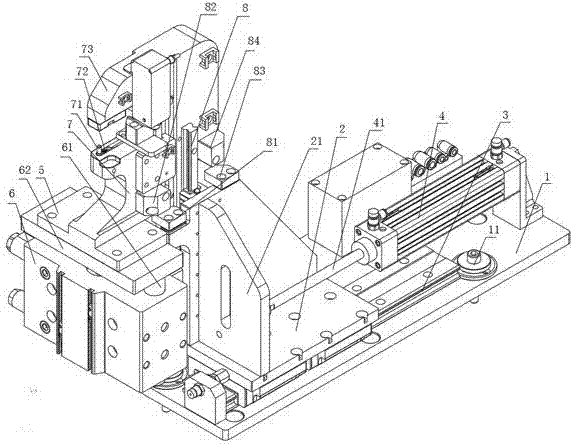

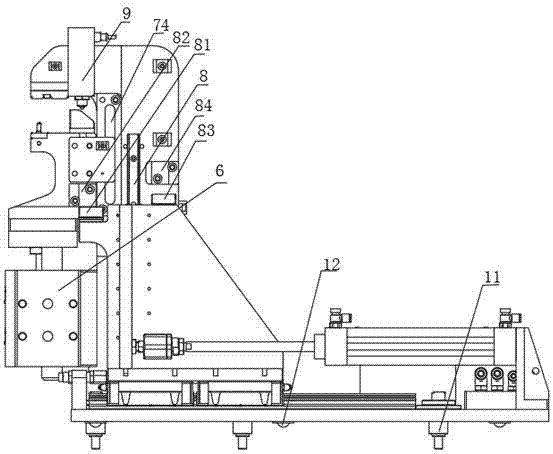

[0028] The technical scheme of the present invention is specifically described below in conjunction with the embodiments. The present invention specifically discloses a floating mechanism for a press-fit threaded steel sleeve, which combines Figure 1-Figure 3 As shown, it includes a bottom plate 1, a first pushing mechanism arranged on one side of the bottom plate 1, and a press-fitting mechanism connected to the first pushing mechanism. One side of the pressing mechanism is also connected with a second pushing mechanism. The bottom of the bottom plate 1 is provided with a positioning pin shaft 11 for positioning, and the positioning pin shaft is a gap pin shaft, and a floating steel ball 12 is also provided on the bottom plate 1 . When the mechanism is in use, the positioning pin 11 at the bottom can be used for preliminary positioning, so that the whole mechanism can easily shake freely in the gap between the pins, and then the floating steel ball 12 can reserve a gap of ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com