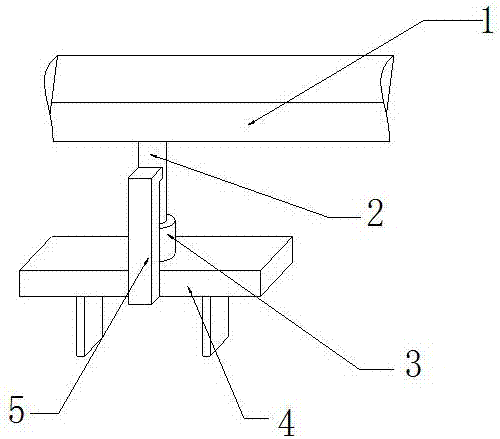

Rapid changeover clamp of industrial robot

An industrial robot, quick-change technology, applied in the direction of manufacturing tools, chucks, manipulators, etc., can solve the problems of untimely replacement of fixtures, falling clamping force, and industrial robot quick-change fixtures without a clamping force detection mechanism. , to achieve the effect of high connection efficiency and improved security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

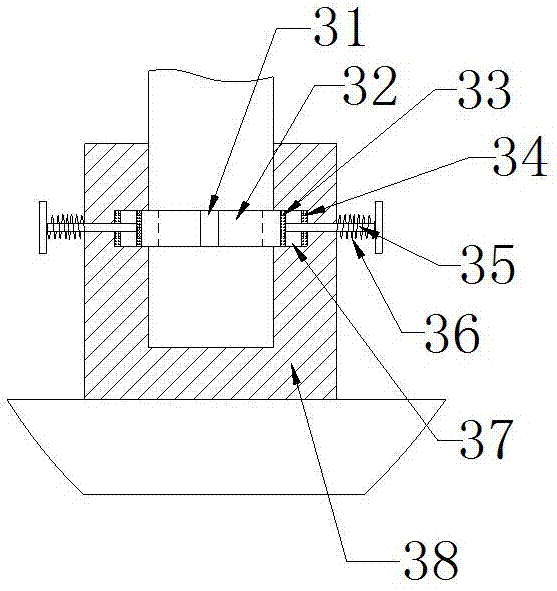

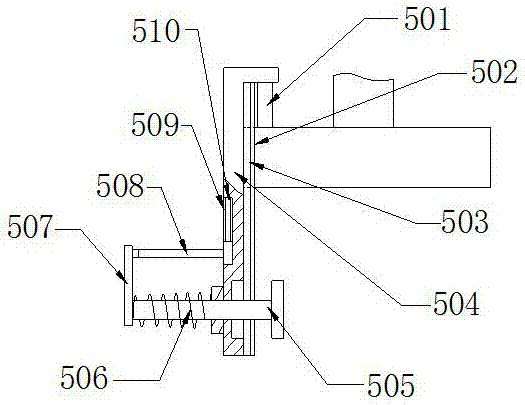

[0023] The specific embodiment: when the staff installs this device, the circuit between the electromagnet 34 and the external power supply is connected, and the electromagnet 34 is energized to generate magnetism, so that the electromagnet 34 generates a magnetic attraction force to the magnet ring 33, thereby making the magnet ring 33 to The electromagnet 34 moves in the direction, the magnet ring 33 moves to drive the clamp ring 32 to move, the clamp ring 32 moves to drive the guide rod 35 to move, and the guide rod 35 moves to generate a tensile force on the spring one 36, so that the spring one 36 is stretched, and the clamp ring 32 moves When reaching the inside of the annular groove 2 37, the staff assembles the connecting cylinder 38 to the lower end of the boom 2, and moves the connecting cylinder 38 along the boom 2. , the circuit between the electromagnet 34 and the external power supply is disconnected, so that the electromagnet 34 loses its magnetism, and under the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com