Independent suspension front axle assembly for commercial vehicle

A technology of independent suspension and front axle assembly, which is applied in the direction of suspension, elastic suspension, vehicle spring, etc., can solve the problems of low reliability, low strength, and inability to meet the requirements of large load, and achieve low cost and high performance. Effects of load carrying capacity, increased mechanical strength and application reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

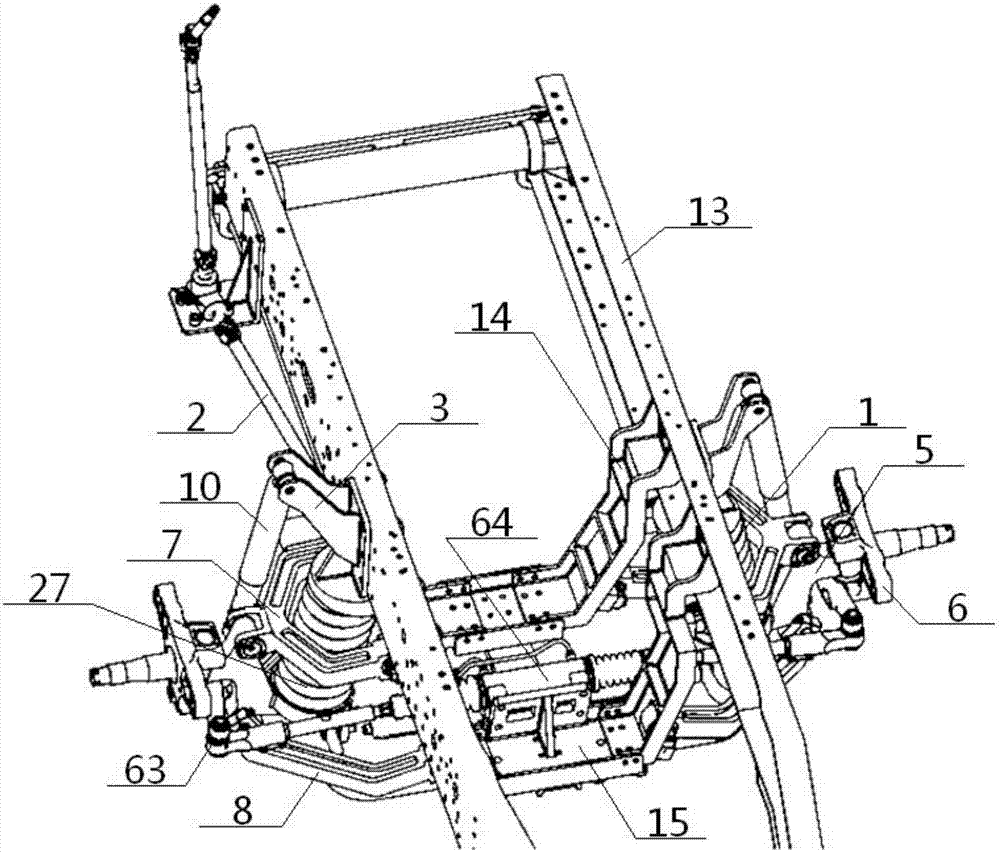

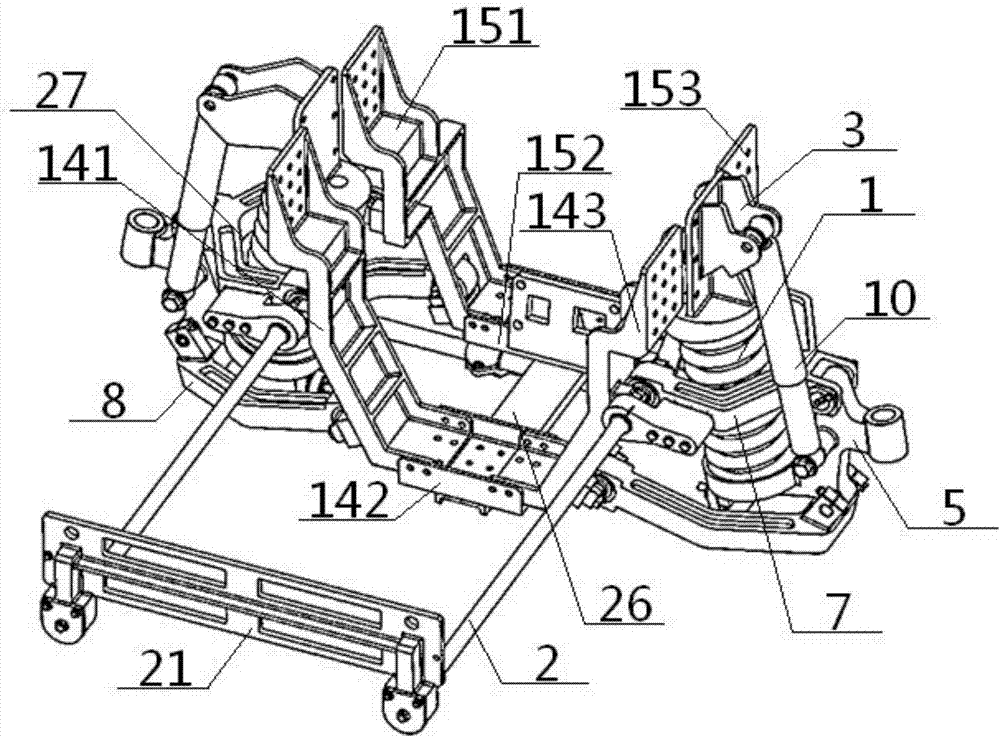

[0065] see Figure 1 to Figure 19 , an independent suspension front axle assembly for a commercial vehicle, comprising a vehicle frame 13, a front bracket assembly 14, a rear bracket assembly 15 and two front independent suspension systems 27, the front bracket assembly 14, the rear bracket Assembly 15 is arranged front and rear along the central axis of vehicle frame 13, and two front independent suspension systems 27 are symmetrically arranged left and right along the central axis of vehicle frame 13, and front independent suspension system 27 is all connected with vehicle frame 13, front bracket assembly 14, The rear bracket assemblies 15 are all connected;

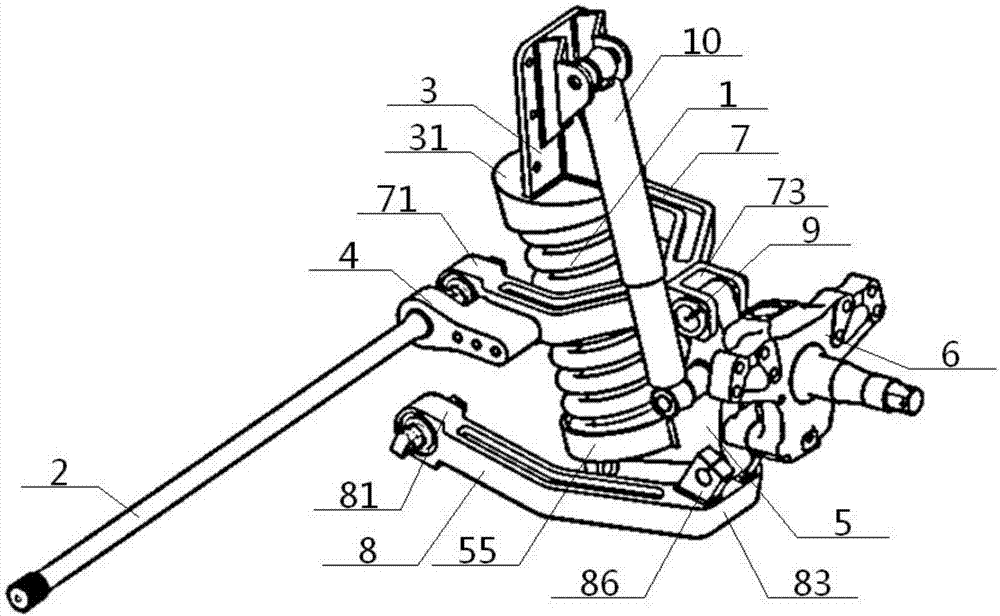

[0066] The front independent suspension system 27 includes a coil spring 1, a torsion bar spring 2, a coil spring mounting bracket 3, a torsion bar spring mounting bracket 4, a steering knuckle bracket 5, a steering knuckle 6, an upper swing arm 7 and a lower swing arm 8, and The steering knuckle bracket 5 is connecte...

Embodiment 2

[0068] Basic content is the same as embodiment 1, the difference is:

[0069] The upper left forearm foot 71, the upper left rear arm foot 72, the lower left forearm foot 81, and the lower left rear arm foot 82 are embedded with a corresponding first rubber bushing 74, a second rubber bushing 75, The third rubber bushing 84, the fourth rubber bushing 85, the axes of the first rubber bushing 74 and the second rubber bushing 75 are coaxial, the third rubber bushing 84, the fourth rubber bushing The axis line of 85 is coaxial. The axis line of the torsion bar spring 2 is parallel to the longitudinal plane of the vehicle frame 13, and the torsion bar spring 2 is located at the front end of the wheel; the shock absorber assembly 10 is located at the front end of the symmetrical center plane of the wheel. The distance between the axis of rotation of the upper swing arm 7 is less than or equal to the distance of the axis of rotation of the lower swing arm 8 , and the upper swing arm...

Embodiment 3

[0071] Basic content is the same as embodiment 1, the difference is:

[0072] The steering knuckle bracket 5 includes a bottom tray 55, a hollow cylinder 54 and an L-shaped bracket body 51. The bracket body 51 includes a bottom bracket arm 52 and a side bracket arm 53 connected to each other, and the inner end of the bottom bracket arm 52 is connected to the bottom tray. The bottom of 55 is connected, and the outer end of bottom support arm 52 is connected with the bottom of side support arm 53, and the top of side support arm 53 is hinged with upper right arm foot 73 by eccentric pin 9, and the outer end of side support arm 53 The position at the junction of the proximal support arm 53 and the upper right arm pin 73 on the side is connected with the outer wall of the hollow tube 54, and the inner wall of the hollow tube 54 is connected with the steering knuckle 6 through the steering kingpin 61, and the side bracket arm The bottom end of 53 is hinged with the lower arm seat 8...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap