Insert block type ball screw pair

A technology of ball screw pairs and balls, which is applied in belts/chains/gears, mechanical equipment, transmission devices, etc., can solve the problems of noise structure and manufacturability, and achieve simplification of processing, reduction of noise and temperature rise, and application The effect of widening the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

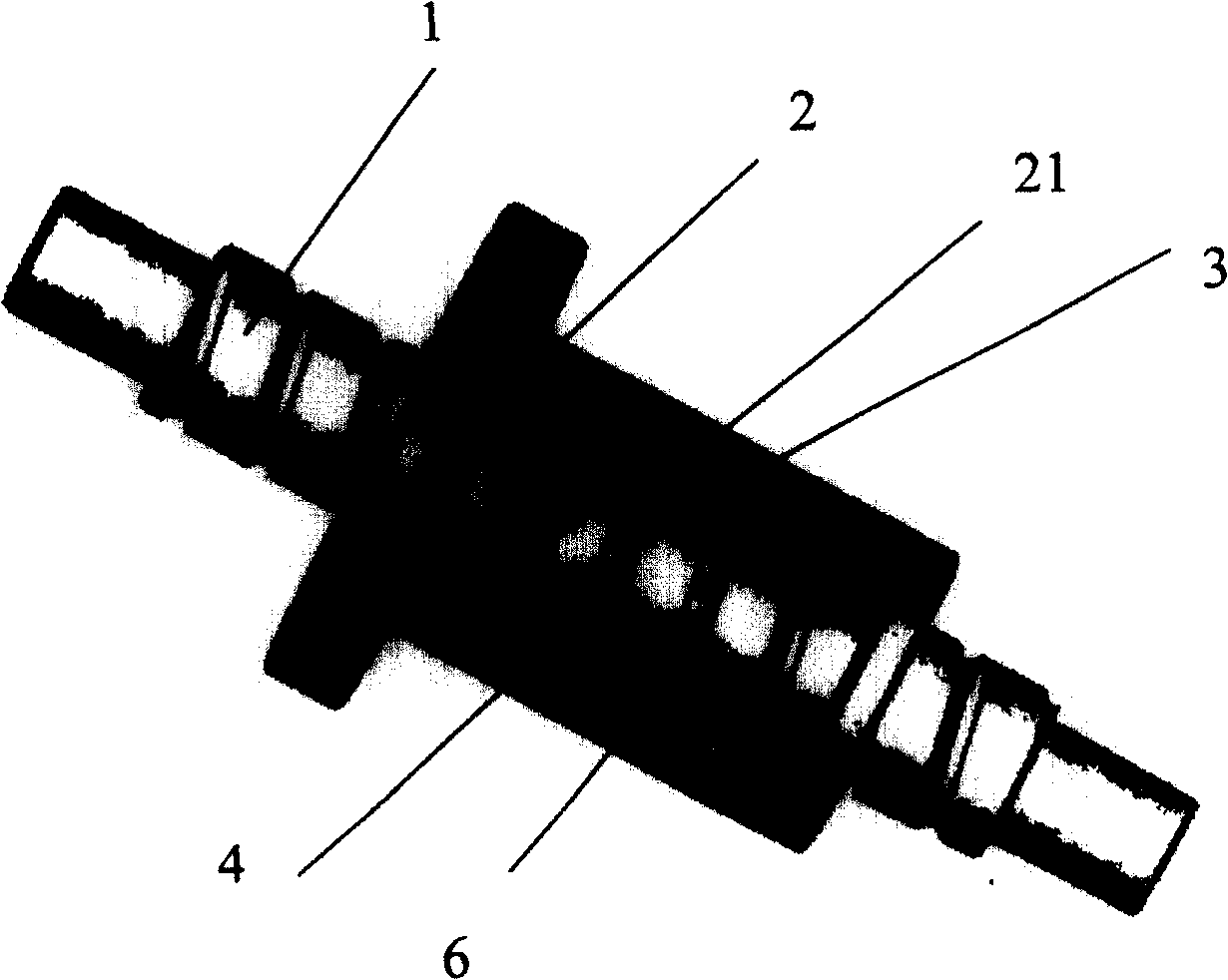

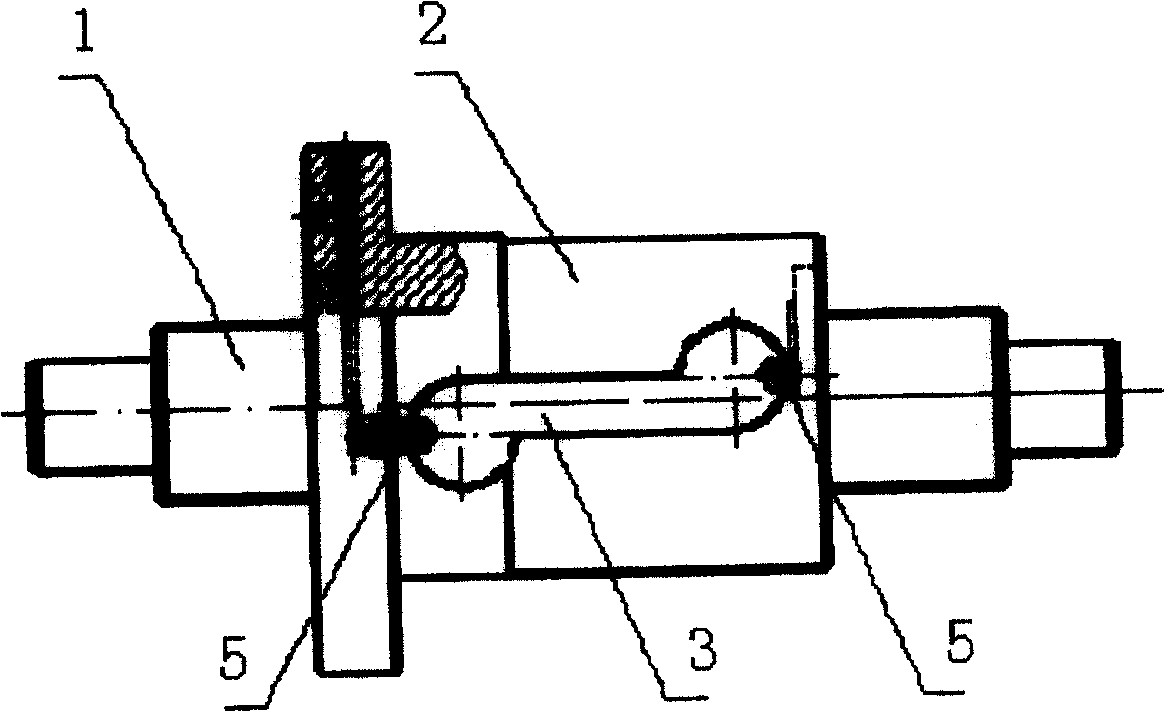

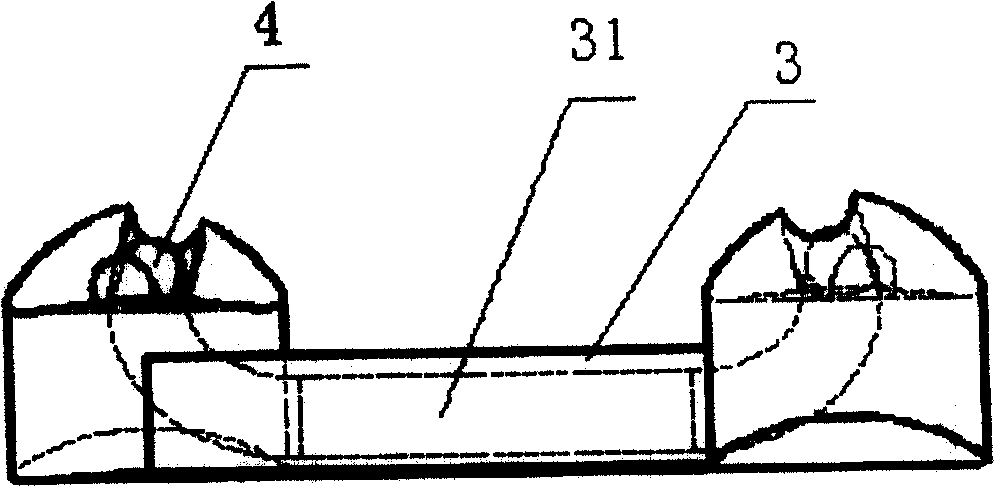

[0030] A single-nut plug-in type ball screw pair according to the present invention, see figure 1 , including a lead screw 1, a nut 2, a reverser 3 and a ball 4, the thread on the lead screw 1 is adapted to the nut 2, and the nut 2 is set on the lead screw 1; a group of balls 4 is arranged on the lead screw 1 and the In the spiral passage formed by the spiral groove of the nut 2, the nut 2 moves on the lead screw 1 through the ball 4 and the reverser 3. The shape of the retroreflector 3 is approximately bone-shaped. The outer circle of the nut 2 is provided with a mounting groove 21 matching the shape of the reverser 3; the mounting groove 21 on the nut 2 is composed of two eccentric circular holes and a straight groove along the direction of the nut busbar, the straight groove The two sides are respectively tangent to the two eccentric circular holes, and the shape of the deflector 3 matches the shape formed by the two holes on the nut 2 and the straight groove. The reverse...

Embodiment 2

[0033] A double-nut washer pre-tightened plug-in ball screw pair according to the present invention, see Figure 6. Including lead screw 1, flange nut 2a, straight nut 2b, adjusting gasket 7, reverser 3, ball 4, spacer 6, etc. Both the flange nut 2a and the straight nut 2b are mounted on the lead screw 1, and the flange nut 2a and the straight nut 2b are fixedly connected by a key 8. An adjusting washer 7 is provided between the flange nut 2a and the straight nut 2b to adjust the pretightening force. The ball 4 and the spacer 6 are installed between the lead screw 1 and the two nuts 2a, 2b, and the thread transmission between the lead screw 1 and the nuts is realized by the ball 4 . The outer circle of the nut is processed with a bone-shaped installation groove 21 for installing the reverser 3, and the bone-shaped reverser 3 is installed in the installation groove 21, and the two ends are fixed with the set screws 5 with tapered ends.

[0034] When working, the ball screw p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap