A pay-off stand for super thin wires

A technology of thin wires and pay-off racks, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve the problems of breaking wires, low wire strength, affecting normal production, etc., and achieves rapid response, The effect of preventing breaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

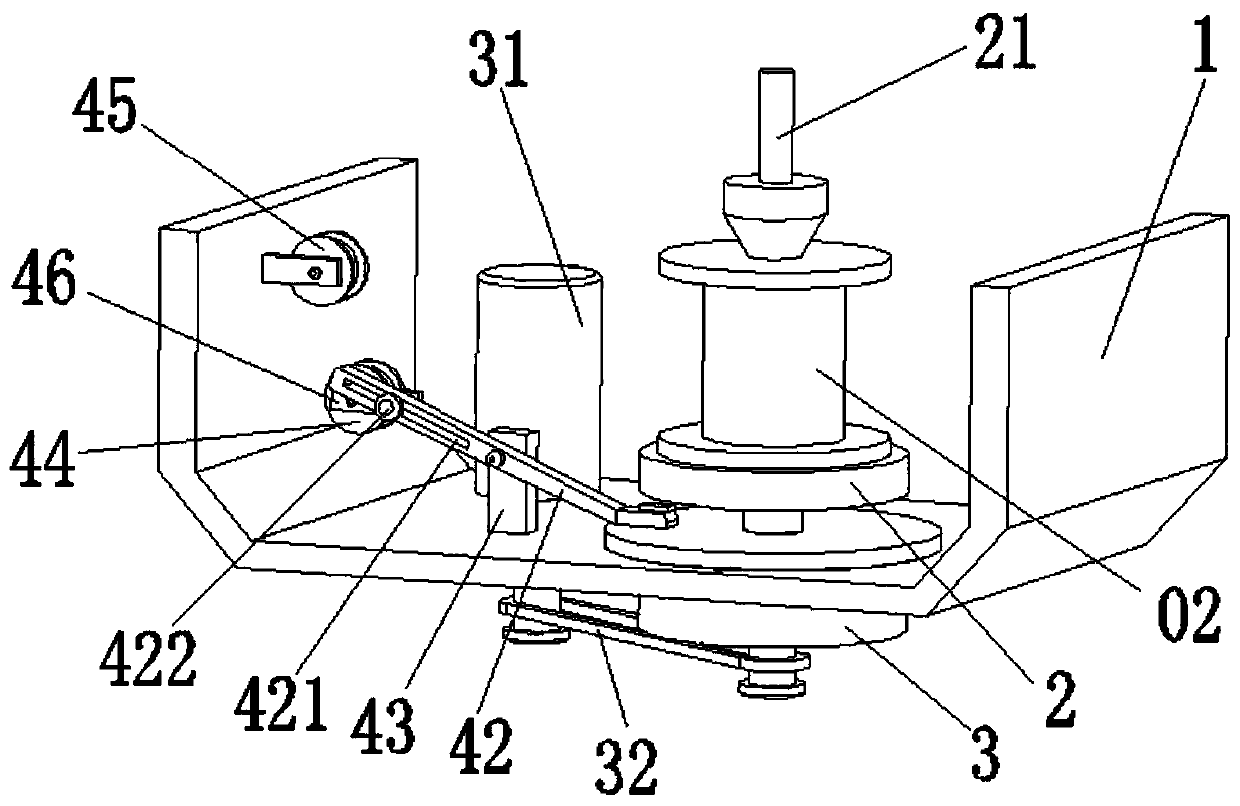

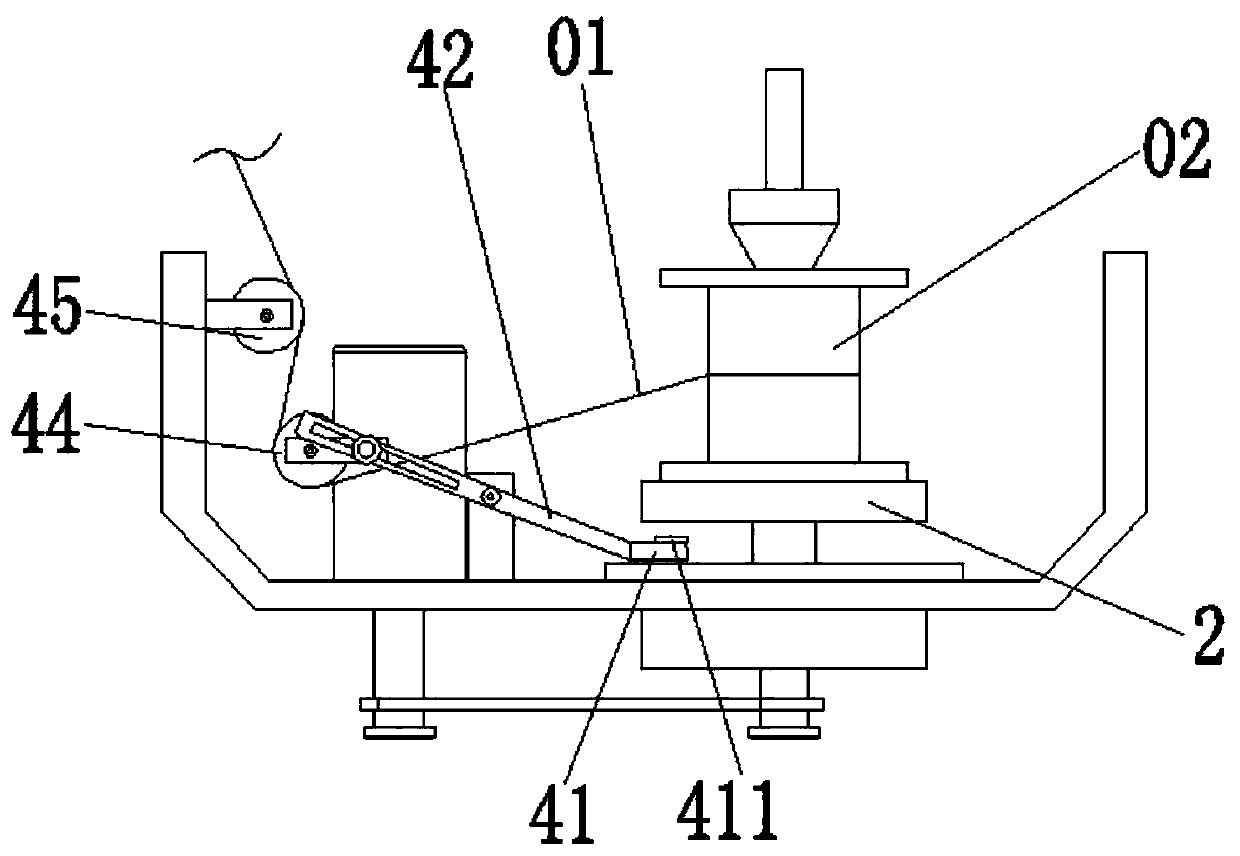

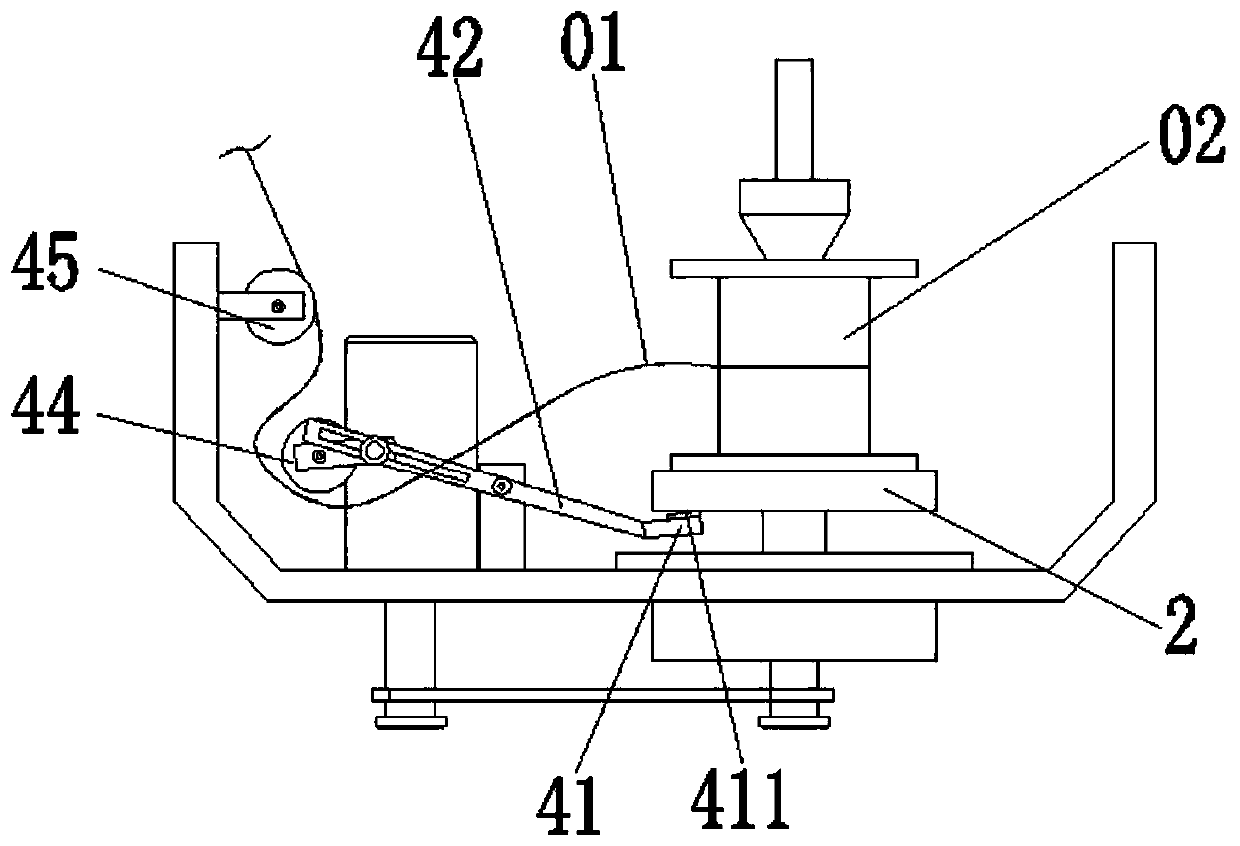

[0032] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0033] The invention provides a pay-off stand for super thin wires, such as Figure 1 to Figure 3 As shown, it includes a bracket 1, a first turntable 2, a second turntable 3 and a motor 31, the first turntable 2 is rotatably mounted on the bracket 1, and the first turntable 2 is provided with a cable reel installation shaft 21 for installing the cable reel 02 , the motor 31 drives the second turntable 3 to rotate, the second turntable 3 is arranged coaxially with the first turntable 2 with a certain distance therebetween, and the second turntable 3 drives the first turntable 2 to rotate through magnetic force.

[0034] Based on the above-mentioned structure, the second turntable 3 and the first turntable 2 of the pay-off frame for super thin wires of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com