A tension-compression type prestressed anchor cable anchoring end device

A prestressed anchor cable and anchored end technology, used in the installation of anchor rods, sheet pile walls, mining equipment, etc., can solve the problems of grouting body damage, anchor cable prestress loss, tensile stress concentration, etc. Optimize the effect of stress bearing and compressive strength improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. However, it can be understood that the following specific embodiments are only preferred technical solutions of the present invention, and should not be construed as limiting the present invention.

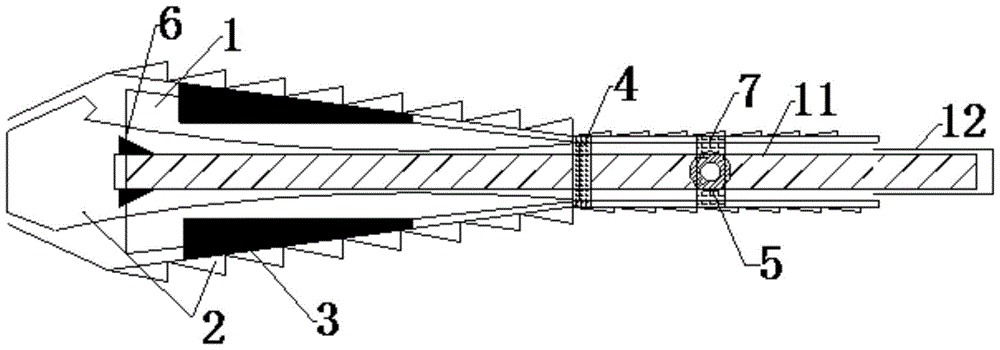

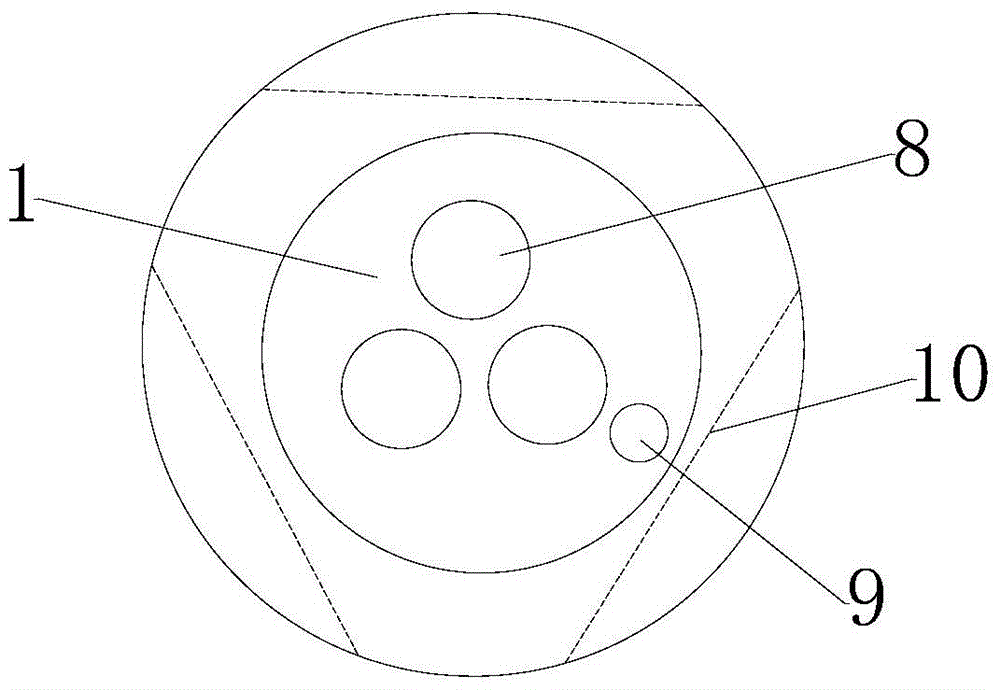

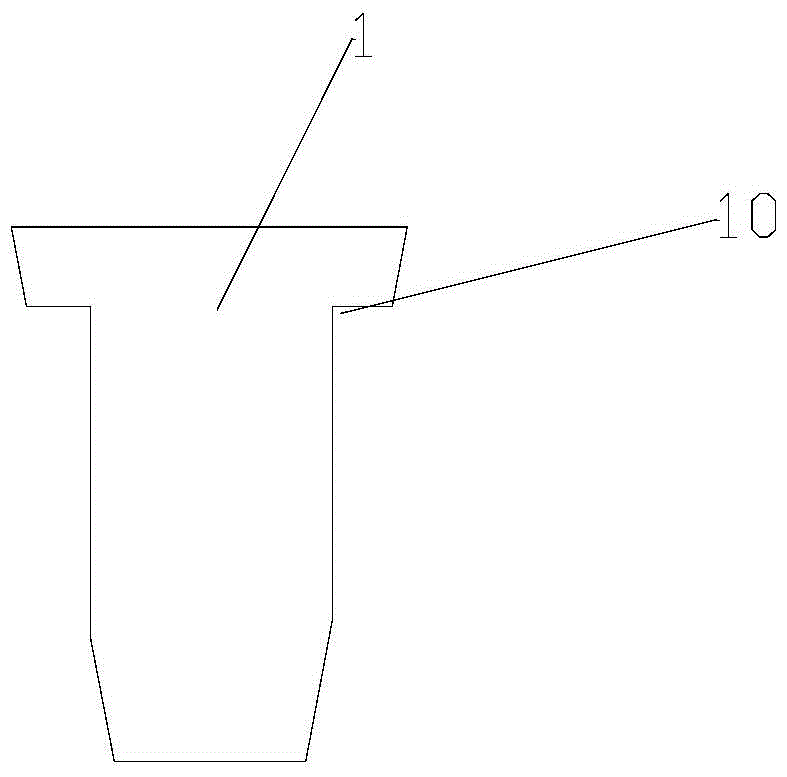

[0022] like figure 1 , figure 2 As shown, a tension-compression type prestressed anchor cable anchoring end device mainly includes an expansion shell inner wedge 1, an expansion piece 2, an extrusion body 3, a hoop ring 4, an extrusion nut 5, a tension sleeve 6, a welding Circular ring 7, the inner wedge 1 of the expansion shell is provided with a perforation 8 and a grouting port 9 for the steel strand 11 to pass through. The diameter of the perforation 8 is set to 20mm, which can be used for Φ13, Φ15, The steel strands 11 of three specifications of Φ18 pass through, and the steel strands 11 are fixedly connected with the inner wedge 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com