a stretch tube

A technology of telescopic tubes and fixed wires, which is applied in the field of hoses, can solve the problems of unsightly appearance of products, easy to get dirty, and dirt, and achieve the effects of increasing market competitiveness, beautiful appearance, and preventing breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

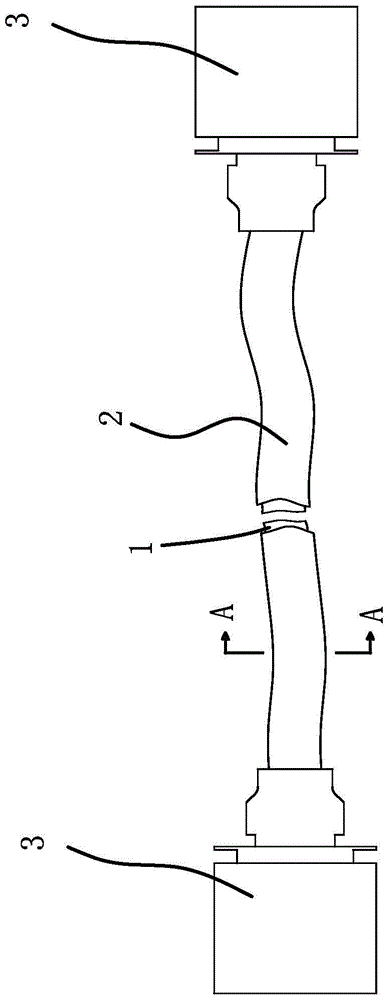

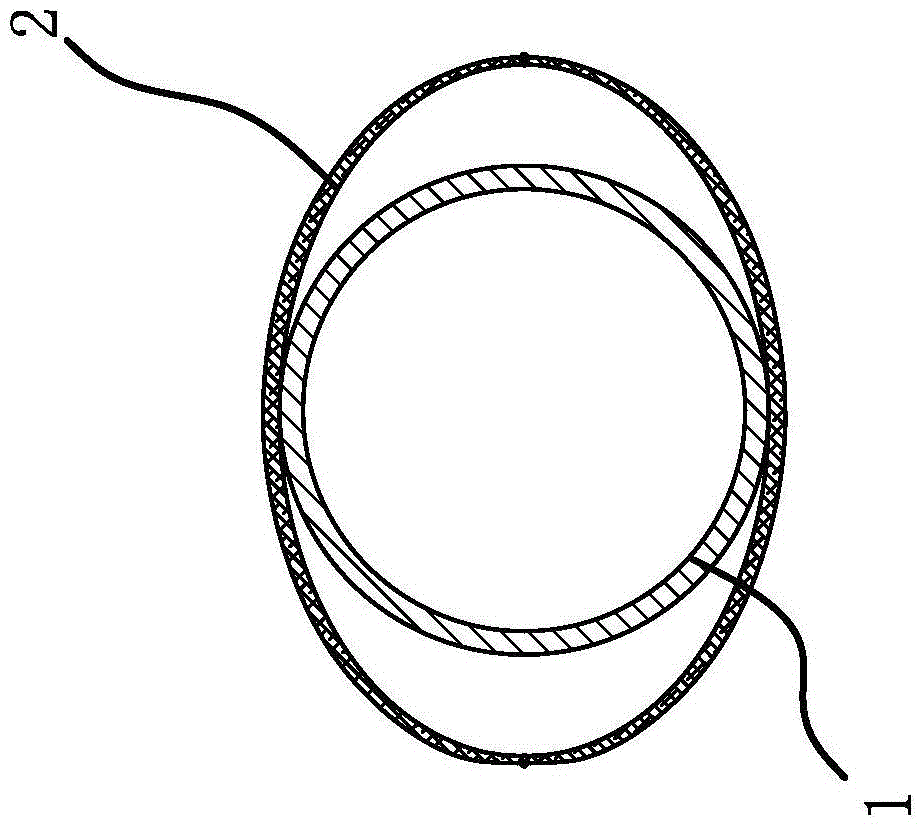

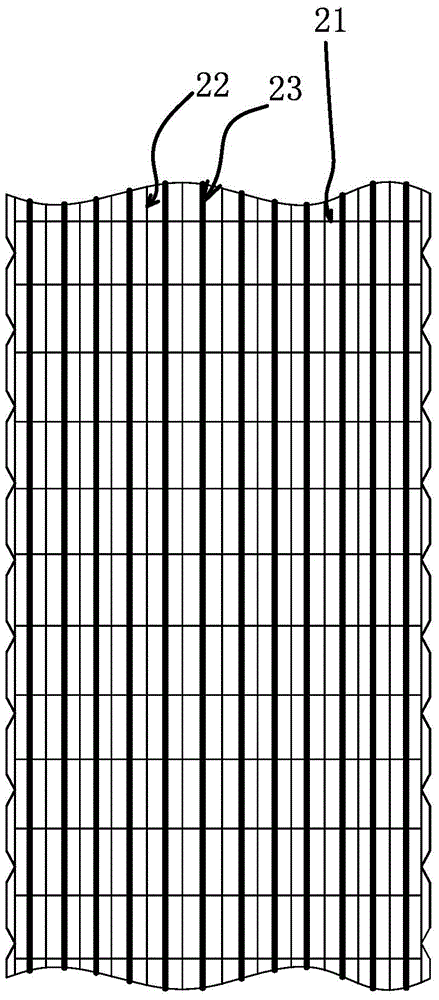

[0025] Such as figure 1 and figure 2 As shown, the telescopic tube includes an outer sleeve 2 and an inner tube 1 disposed inside the outer sleeve 2 , the outer sleeve 2 is in a straight cylindrical shape, and the two ends of the outer sleeve 2 and the inner tube 1 are respectively fixed together by connectors 3 . The connector 3 includes a connecting sleeve with a through hole and a locking ring. One end of the connecting sleeve can be connected to a spray gun or a water gun, and the other end of the connecting sleeve is connected to the outer sleeve 2 and the inner pipe 1. The locking ring is threaded on the other end of the connecting sleeve. At one end, there are two clamping washers between the locking ring and the coupling sleeve. When the outer jacket 2 and the inner tube 1 are put on the connecting sleeve, the locking ring is fixed on the connecting sleeve, and the locking ring clamps two clamping washers so as to tightly fix the outer jacket 2 and the inner tube 1 o...

Embodiment 2

[0032] The structure and principle of this embodiment are basically the same as those of Embodiment 1, except that the warp thread is elastic yarn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com