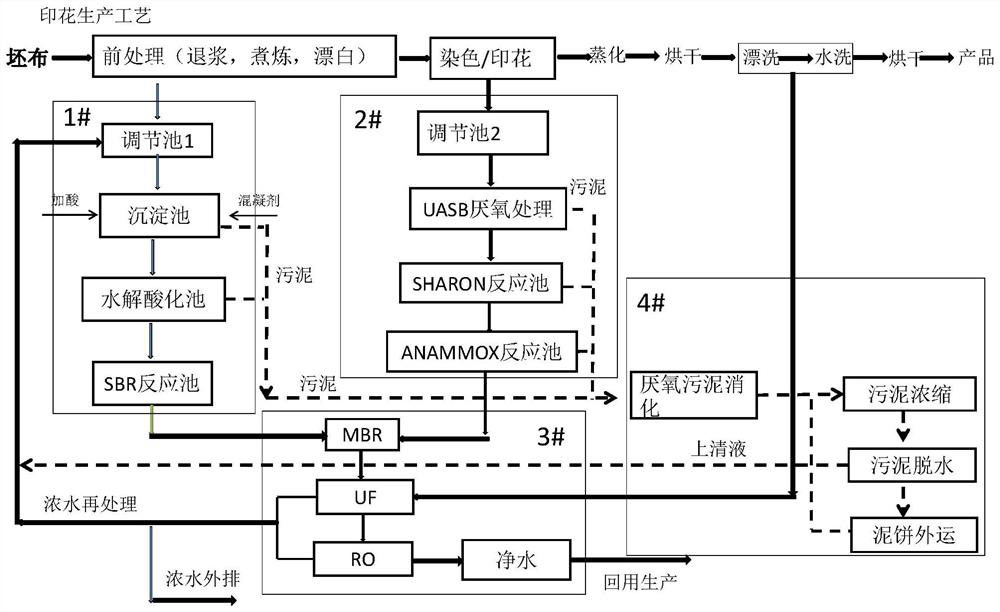

A high-nitrogen printing wastewater treatment and reuse system and its application method

A printing wastewater and high nitrogen technology, which is applied in textile industry wastewater treatment, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems of difficult denitrification of printing wastewater, shorten the hydraulic retention time, and avoid sludge Effect of swelling, high biophase concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A textile limited liability company has an annual natural output of 6,500 tons of cotton yarn, 1,000 tons of knitted gray cloth, and 4.5 million pieces of knitwear. It is a textile enterprise integrating cotton spinning, knitting, printing and dyeing, and garment making. The dyeing and finishing wastewater of this enterprise is divided into desizing wastewater and wastewater generated during the printing process. The amount of desizing wastewater is 1600-2000m 3 / d, the amount of printing wastewater is 800~1000m 3 / d, desizing wastewater COD Cr The concentration is 20000~30000mg / L, COD Cr / BOD<0.3, belongs to refractory biodegradable wastewater. The nitrogen content of printing wastewater reaches 300-500mg / L, and the COD concentration is also 2000-3000mg / L. big. In order to meet the discharge standards and reduce operating costs, the company decided to adopt the high nitrogen printing wastewater treatment and recycling system integration process of the present invent...

Embodiment 2

[0047] A textile company is a large knitting printing and dyeing enterprise in China. It produces a combination of knitting and printing and dyeing, with a displacement of 10,000-12,000m 3 / d, the discharged wastewater contains a large amount of complex components such as residual dyes, slurry, surfactants, and alkali agents, and has the characteristics of large chroma, high concentration of organic matter, strong alkalinity, and large changes in water quality and quantity. The removal effect of chemical and biological methods is not ideal. The company's desizing wastewater volume is 6000 ~ 8000m 3 / d, the amount of printing wastewater is 2000-4000m 3 / d, desizing wastewater COD Cr The concentration is 20000~30000mg / L, COD Cr / BOD<0.3 belongs to refractory biodegradable wastewater. The nitrogen content of printing wastewater reaches 300-500mg / L, and the COD concentration is also 2000-3000mg / L. big. In order to meet the discharge standards and reduce operating costs, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com